Convenience type foam cutting device

A cutting device and a portable technology, applied in the field of portable foam cutting devices, can solve the problems of high cost of use, low processing efficiency, inconvenient processing, etc., and achieve the effects of low cost of use, high processing efficiency and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

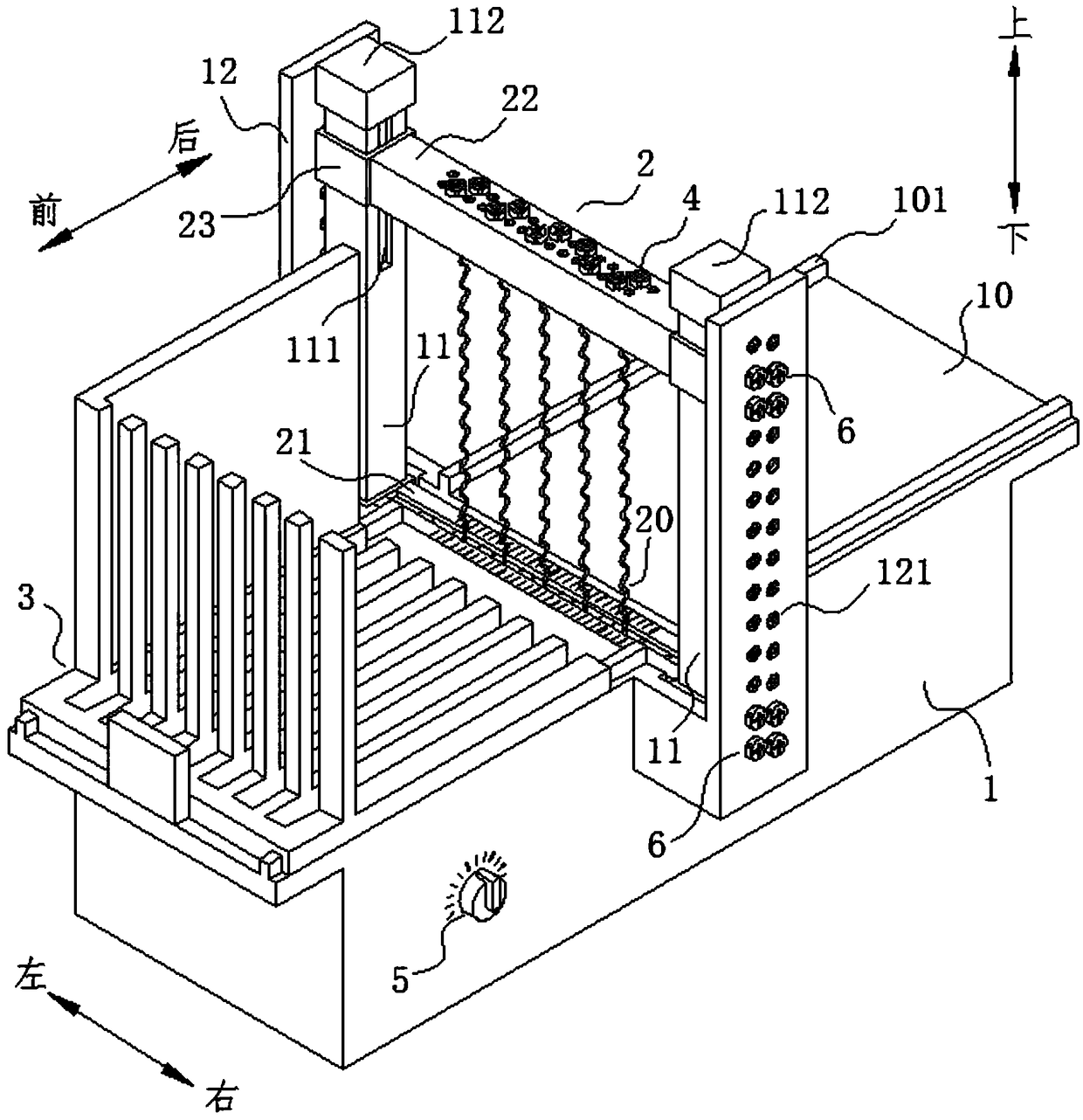

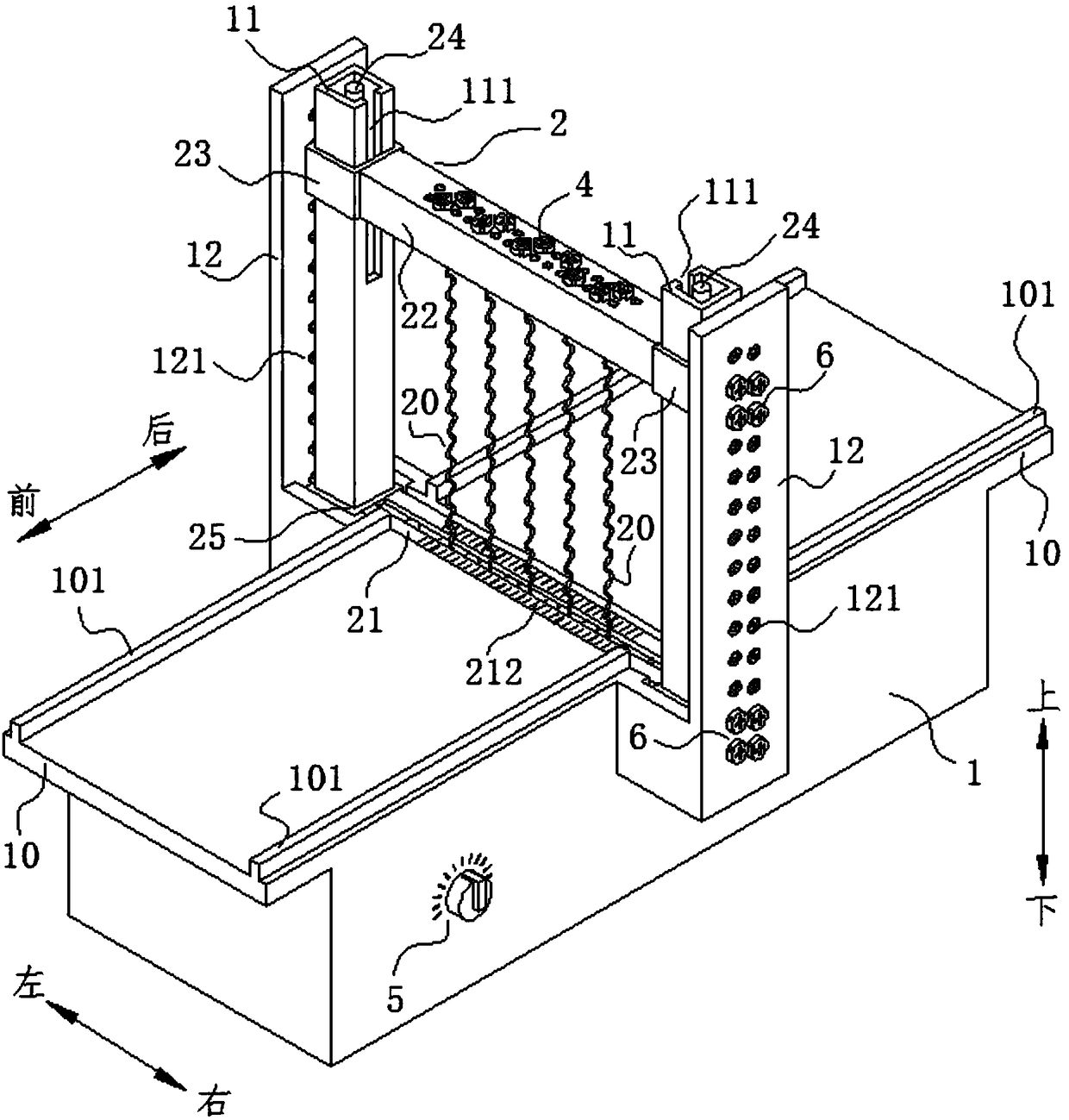

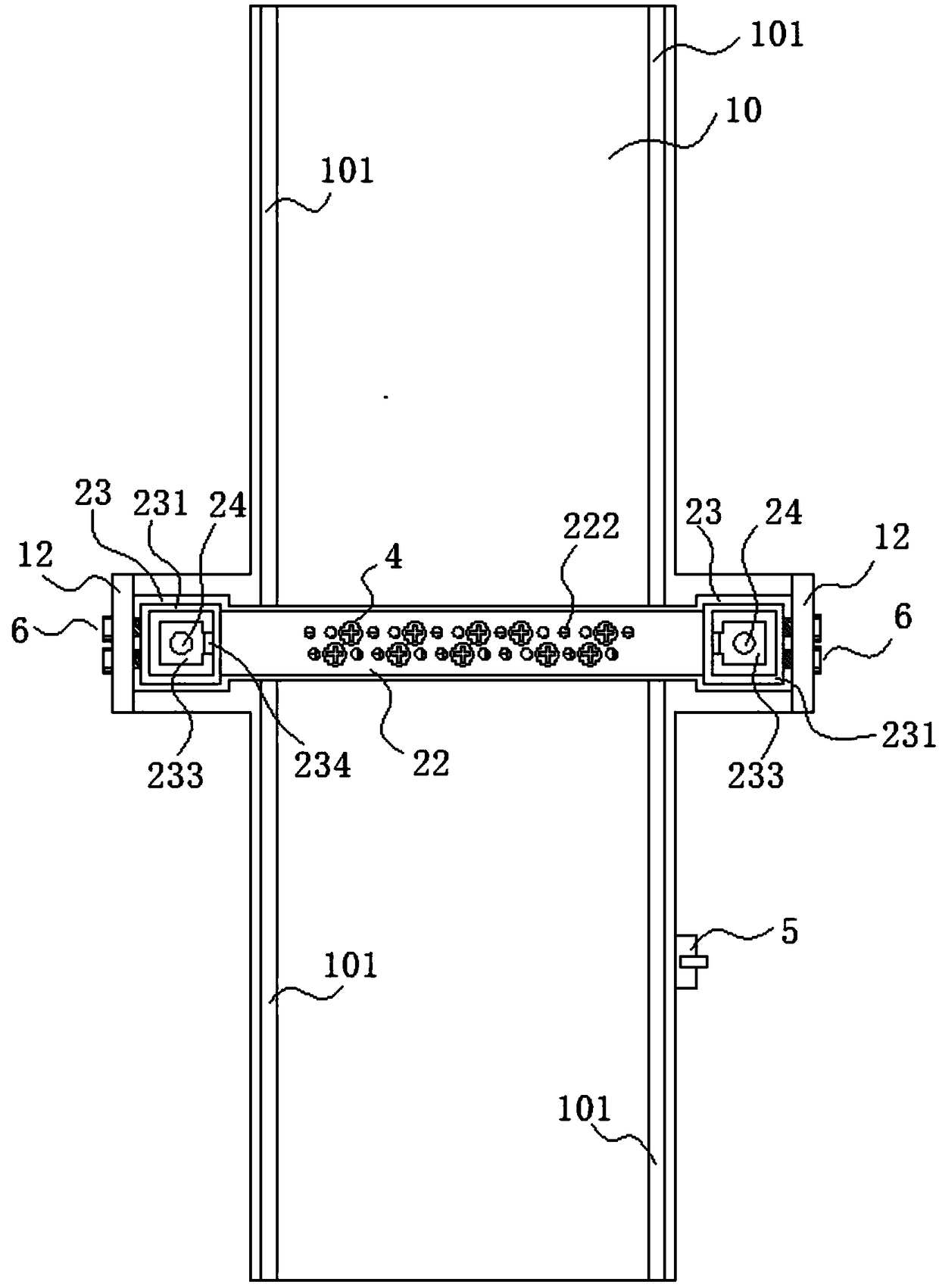

[0033] This embodiment provides a portable foam cutting device, such as Figure 1 to Figure 7 As shown, it includes a base 1 provided with a workbench 10, vertical conductive rods 24 that are vertically arranged on both sides of the base 1 and extend upward, and vertical conductive rods 24 that are respectively covered on the peripheral sides of the vertical conductive rods 24. Guide sleeve 11, a plurality of heating wires 20, and an upper conductive rod 27 and a lower conductive rod 26 for supplying power to a plurality of the heating wires 20 and respectively connected to two poles of the power supply; the two ends of the lower conductive rod 26 can be respectively The sliding sleeve 25 is disassembled and fixedly connected, and the upper side of the workbench 10 is provided with a storage groove 13 for accommodating the lower conductive rod 26 and the sliding sleeve 25, and the sliding sleeve 25 is slidingly sleeved on the vertical on the guide sleeve 11 and set in the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com