Four-speed-gear single-motor hybrid power assembly

A technology of hybrid power and single motor, which is applied in the field of vehicle hybrid power to achieve the effects of small torque, low power consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

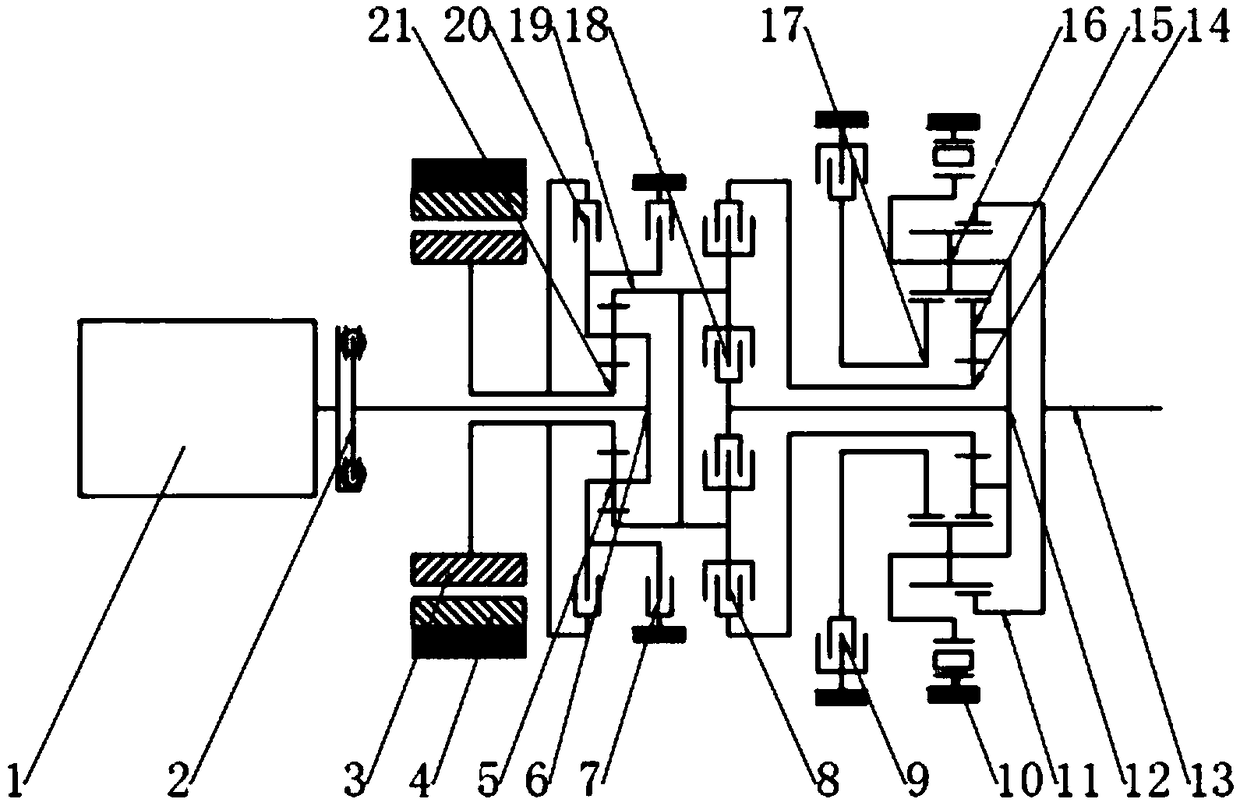

[0032] In order to solve the above technical problems, the present invention discloses a four-speed single-motor hybrid powertrain, see figure 1 , the hybrid powertrain includes an engine 1, an electric motor, a coupling planetary row, a transmission, a third clutch 20 and a second brake clutch 7, and the engine 1 and the electric motor serve as the transmission device through the coupling planetary row The power is transmitted to drive the vehicle through the output shaft 13 .

[0033] Specifically, the engine 1 includes an engine output shaft, the electric motor includes a motor rotor 3 and a motor stator 4, and the coupling planetary row includes a third sun gear 21, a third planetary gear 5, a second frame 6 and a second tooth ring 19, the engine 1 is connected to the second ring gear 19 through the engine output shaft, the motor is connected to the third sun gear 21 through the motor rotor 3, and the motor stator 4 is the motor rotor 3 provide electromagnetic driving for...

Embodiment 2

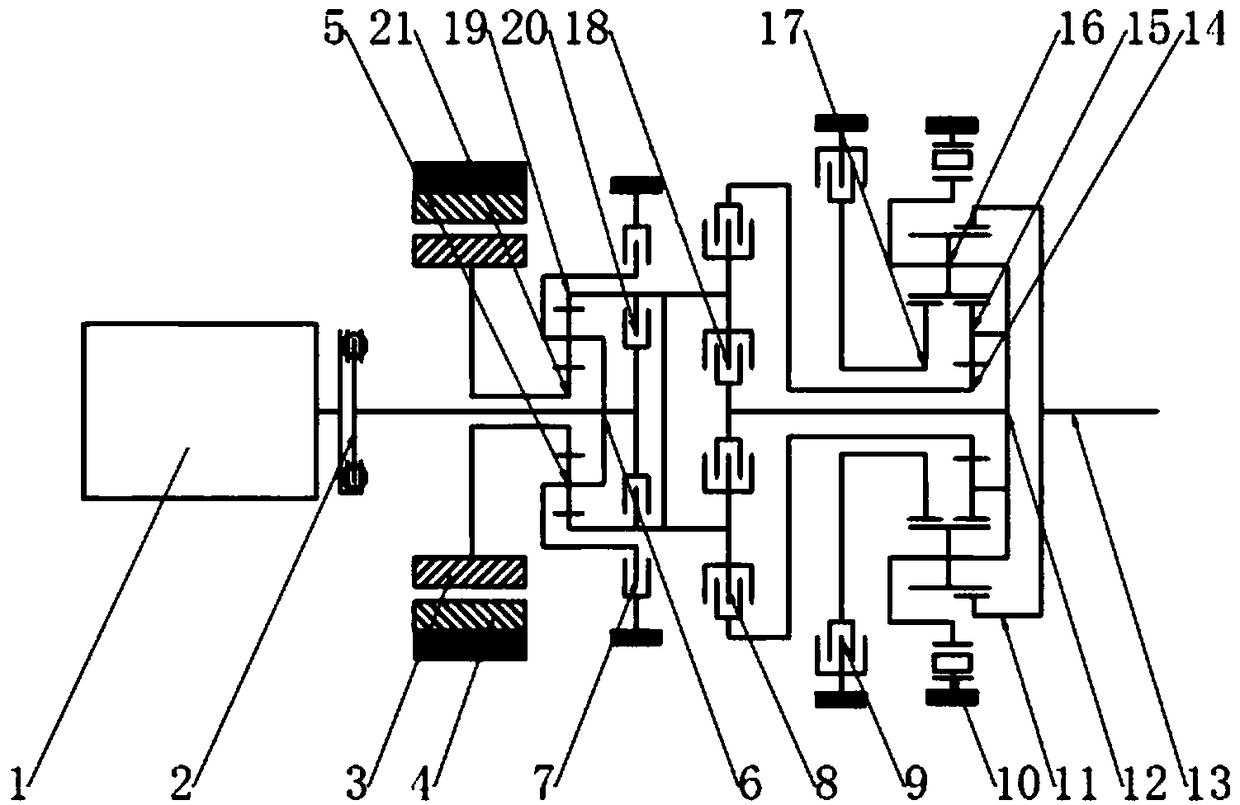

[0058] In this embodiment, different from Embodiment 1, refer to figure 2 1. The connection mode of the third clutch 20 is different, and the other connection modes are the same as those in the first embodiment. refer to figure 2 , one end of the third clutch 20 is connected to the second frame 6, and the other end is connected to the second ring gear 19. Preferably, the driving end of the third clutch 20 is connected to the second frame 6 connected, the passive end of the third clutch 20 is connected with the second ring gear 19 . The functions realized by the hybrid power in this embodiment are the same as the functions realized in Embodiment 1, and the principle of realizing the functions is also the same, which will not be repeated here.

Embodiment 3

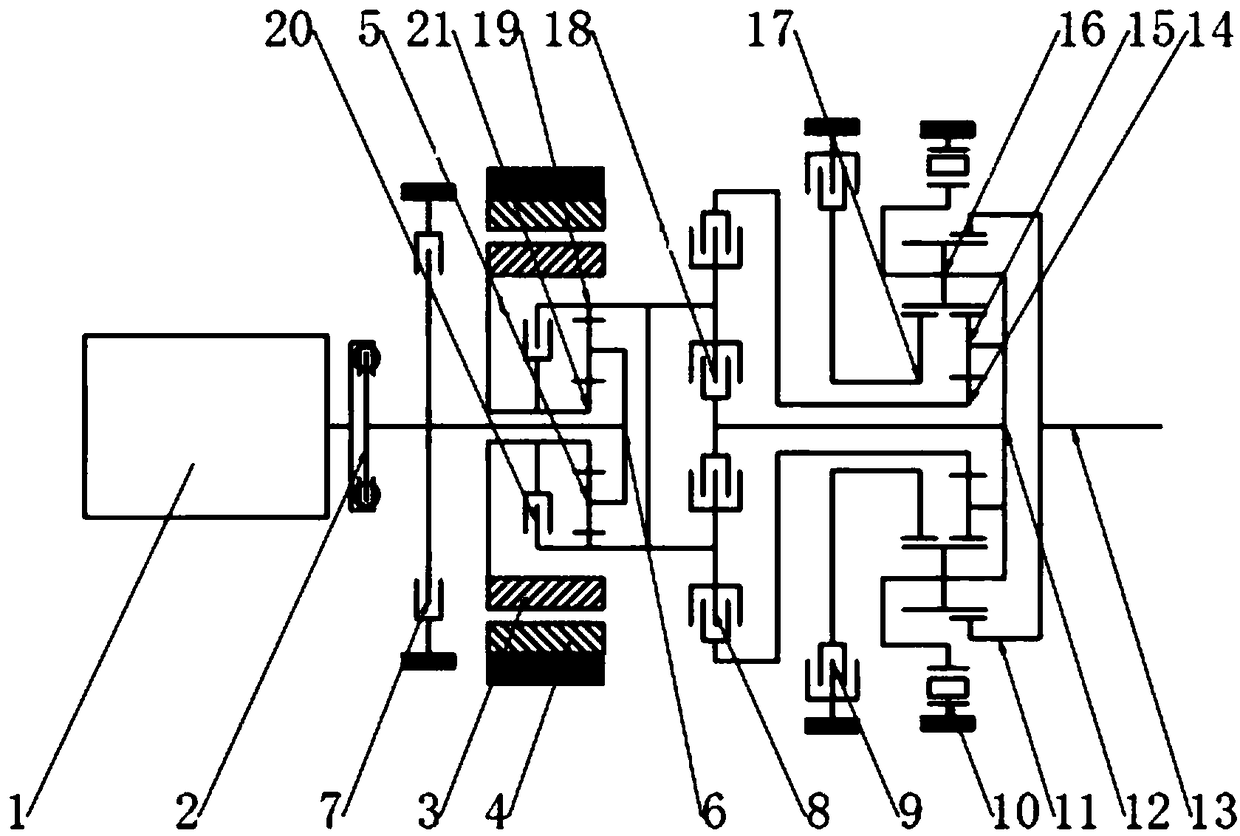

[0060] In this embodiment, different from Embodiment 1, refer to image 3 1. The connection mode of the third clutch 20 is different, and the other connection modes are the same as those in the first embodiment. refer to image 3 , one end of the third clutch 20 is connected with the third sun gear 21 , and the other end is connected with the second ring gear 19 . Preferably, the driving end of the third clutch 20 is connected to the third sun gear 21 , and the passive end of the third clutch 20 is connected to the second ring gear 19 . The functions realized by the hybrid power in this embodiment are the same as the functions realized in Embodiment 1, and the principle of realizing the functions is also the same, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com