Lens coating machine with pneumatic door

A pneumatic door and coating machine technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of uneven coating thickness, bubbles in coating, affecting production efficiency and quality, etc. Coating effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

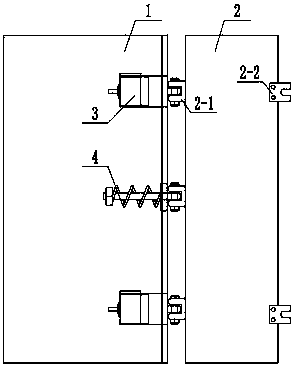

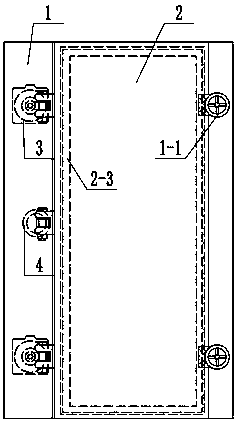

[0011] Depend on figure 1 , figure 2 It is known that a schematic diagram of a lens coating machine with a pneumatic door in the present invention is composed of a coating machine cabin body 1, a coating machine cabin door 2, a cylinder 3, and a shock-absorbing spring assembly 4. Two cylinders 3 are symmetrically installed on the side of the coating machine cabin body 1. Above, the damping spring assembly 4 is installed on the side of the coating cabin body 1 and is in the middle of the two cylinders 3. The left side of the coating cabin door 2 is provided with three U-shaped lifting lugs 2-1, two U-shaped lifting lugs 2-1 up and down. The U-shaped lifting lugs 2-1 are respectively connected with the two cylinders 3 through pins, and the middle U-shaped lifting lugs 2-1 are connected with the damping spring assembly 4 through pins. The right side of the coating machine cabin door 2 is symmetrical up and down. Two U-shaped fixed blocks 2-2 are provided, corresponding to the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com