Launching floating transportation and underwater assembly process of fabricated comprehensive pipe gallery

A comprehensive pipe gallery and prefabricated technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of difficult precipitation, difficulty in ensuring the quality of concrete pouring at the stubble position, and reduce construction costs, pavement and foundation. Dealing with the Effects of Construction Steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

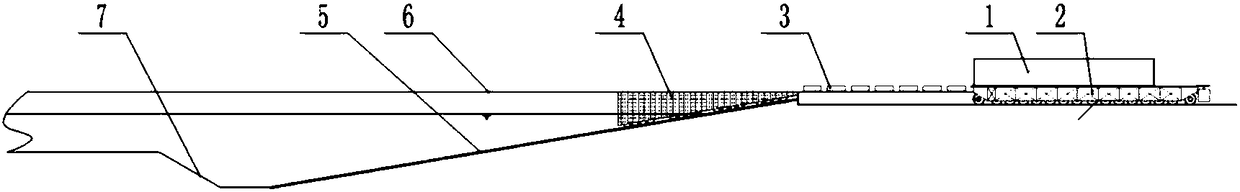

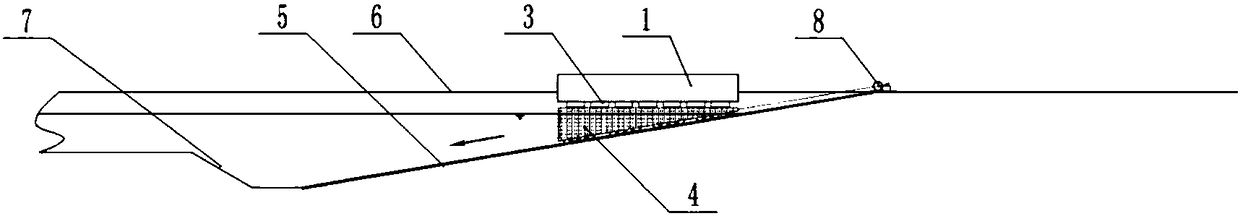

[0029] The launching, floating and underwater assembly process of the prefabricated comprehensive pipe gallery includes the following steps:

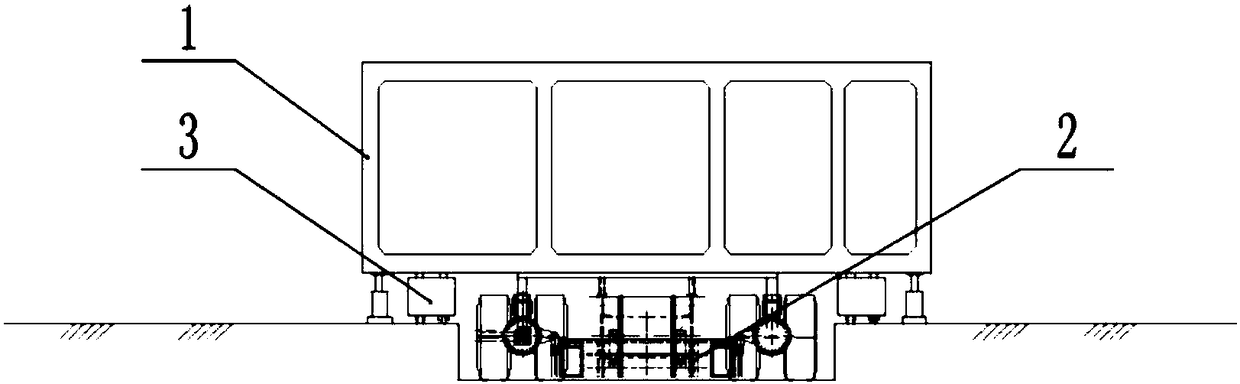

[0030] a. Use a pipe gallery pipe section 1 with a weight of 40 tons per linear meter and a prefabricated length of 20 meters in each section. The interior of the pipe gallery pipe section 1 is installed with a combined water-stop seal plate, and the water-stop seal plate The pipe section 1 of the pipe gallery is fixed with steel oblique supports, and the pipe section 1 of each section of the pipe gallery is transported horizontally between the prefabrication site and the site by a beam transport vehicle 2;

[0031] b. After the pipe gallery pipe section 1 is transported to the site, use a jack to lift it up, the beam transport vehicle 2 drives out, the rail car 3 is located on the ground line 6, the rail car 3 is pulled to the bottom of the pipe gallery pipe section 1, and the jack falls to move the pipe gallery The pipe joint 1 is pla...

Embodiment 2

[0038] The launching, floating and underwater assembly process of the prefabricated comprehensive pipe gallery includes the following steps:

[0039] a. Use a pipe gallery pipe joint 1 with a weight of 45 tons per linear meter and a prefabricated length of 20 meters in each section. The interior of the pipe gallery pipe joint 1 is installed with a combined water-stop seal plate, and the water-stop seal plate The pipe section 1 of the pipe gallery is fixed with steel oblique supports, and the pipe section 1 of each section of the pipe gallery is transported horizontally between the prefabrication site and the site by a beam transport vehicle 2;

[0040] b. After the pipe gallery pipe section 1 is transported to the site, use a jack to lift it up, the beam transport vehicle 2 drives out, the rail car 3 is located on the ground line 6, the rail car 3 is pulled to the bottom of the pipe gallery pipe section 1, and the jack falls to move the pipe gallery The pipe joint 1 is placed ...

Embodiment 3

[0047] The launching, floating and underwater assembly process of the prefabricated comprehensive pipe gallery includes the following steps:

[0048] a. Use a pipe gallery pipe joint 1 with a weight of 43 tons per linear meter and a prefabricated length of 20 meters in each section. The interior of the pipe gallery pipe joint 1 is installed with a combined water-stop seal plate, and the water-stop seal plate The pipe section 1 of the pipe gallery is fixed with steel oblique supports, and the pipe section 1 of each section of the pipe gallery is transported horizontally between the prefabrication site and the site by a beam transport vehicle 2;

[0049] b. After the pipe gallery pipe section 1 is transported to the site, use a jack to lift it up, the beam transport vehicle 2 drives out, the rail car 3 is located on the ground line 6, the rail car 3 is pulled to the bottom of the pipe gallery pipe section 1, and the jack falls to move the pipe gallery The pipe joint 1 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com