Inflow vertical shaft for reducing gas explosion intensity of urban deep drainage system

A drainage system and shaft technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problem of gas explosion, incorrect air circulation channel position, and any protective measures for intercepted air masses that are difficult to meet the rain and sewage inflow capacity during heavy rains at the same time and other problems, to achieve the effect of improving the phenomenon of gas explosion, safe and stable operation, and alleviating intermittent severe surges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

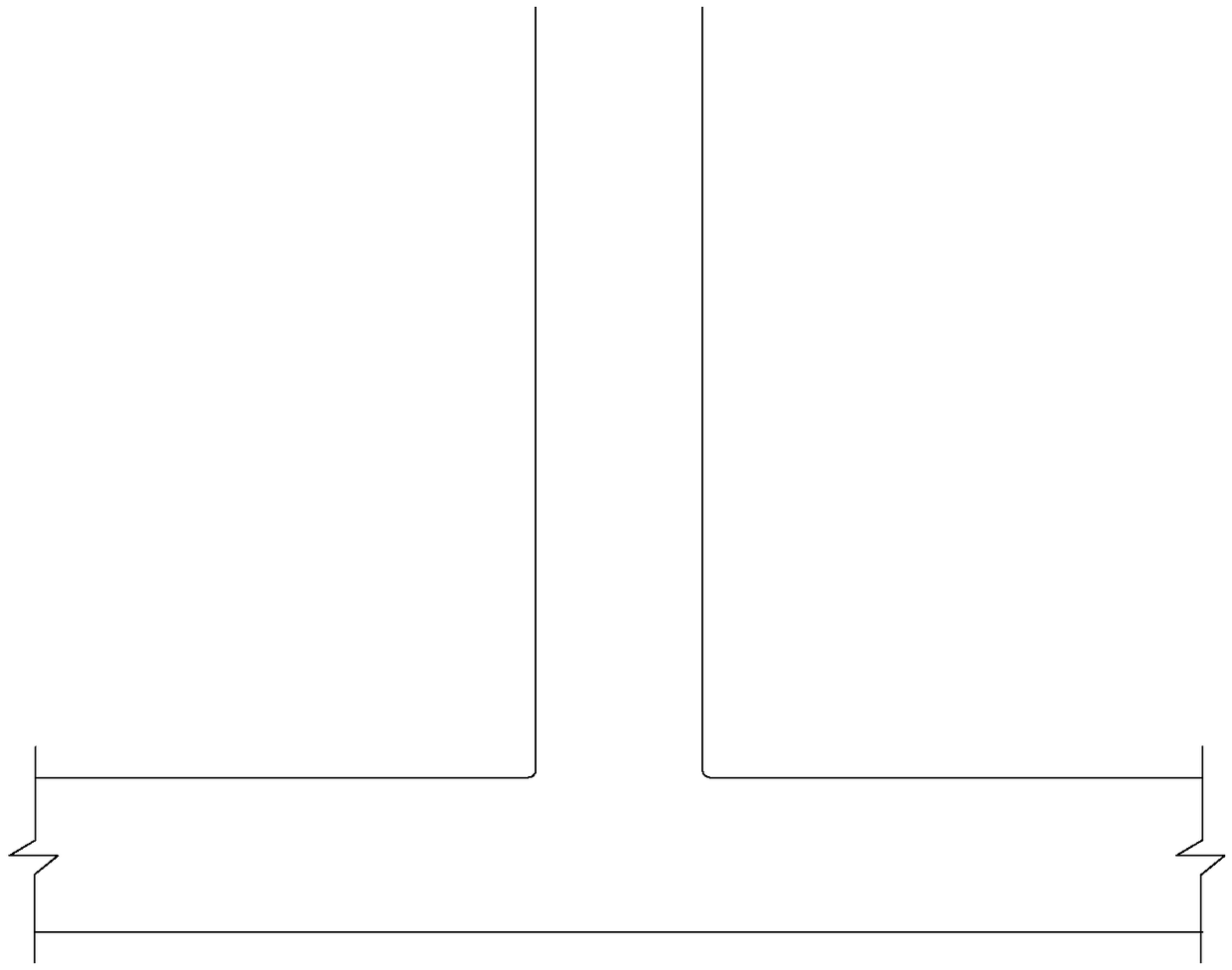

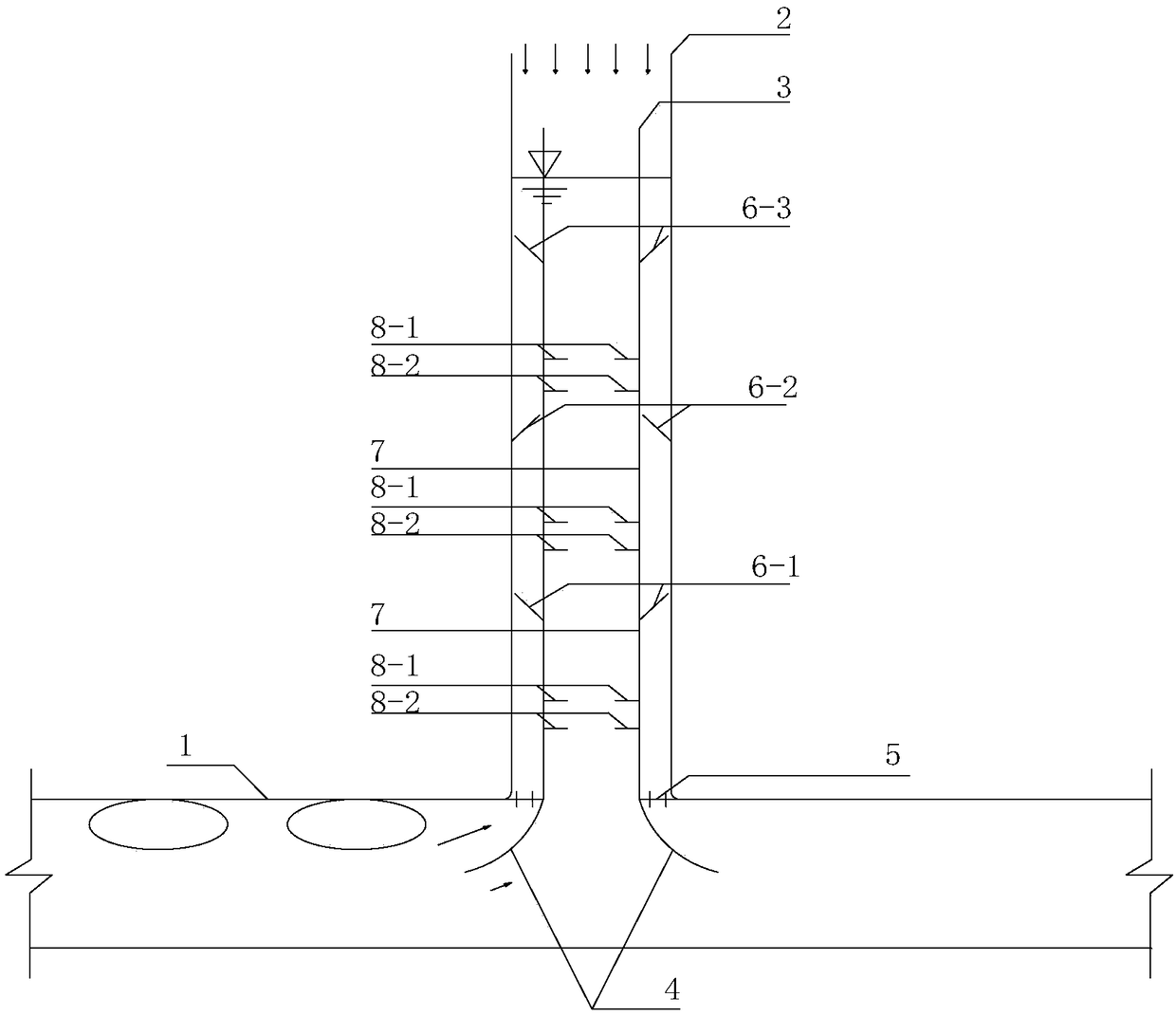

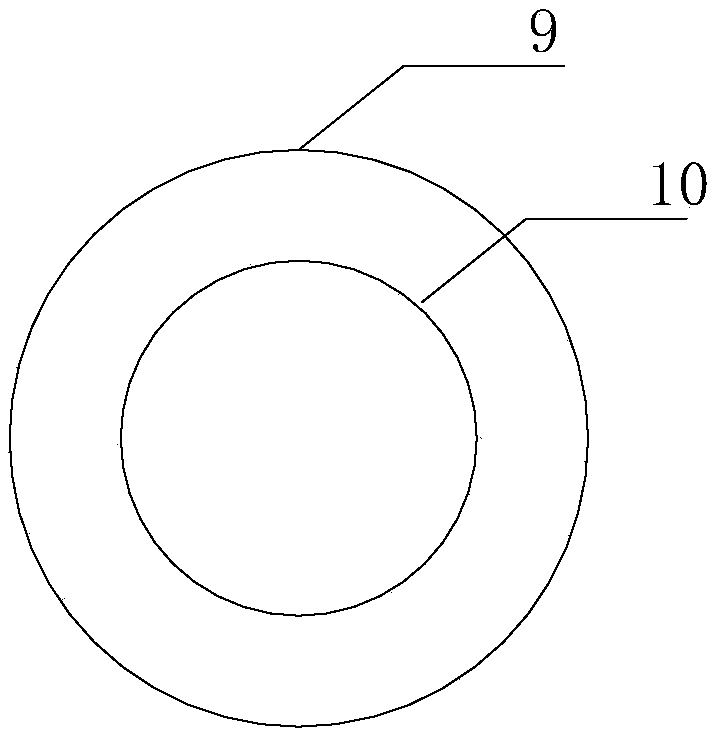

[0040] The drainage pipe inflow shaft device used to improve the gas explosion phenomenon in this embodiment is as follows: figure 2 As shown, a cylinder 3 is arranged on the upper part of the inflow shaft 2 of the deep tunnel 1 . A supporting ring 5 is sleeved between the shaft 2 and the cylinder 3 for fixing the cylinder 3 . The bottom end of the cylinder 3 is provided with an annular bell mouth 4, which guides the trapped air mass into the interlayer between the inflow shaft 2 and the cylinder 3, and plays the role of gas collection. The air hole rings 6-1 to 6-3 are arranged in the interlayer to fully divide the air cavity into air bubbles. Part of the air bubbles are discharged from the interlayer to the outside of the well, and the other bubbles rise up along the inner wall of the cylinder 3 through the pores 7 of the cylinder wall. Under the action of the partitions 8-1 to 8-2, they avoid re-polymerization and are discharged to the outside of the cylinder. Through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com