Expanded graphite composite heat storage material, as well as preparation method and application thereof

A technology of expanded graphite and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of slow dehydration kinetics and restrictions on the large-scale application of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

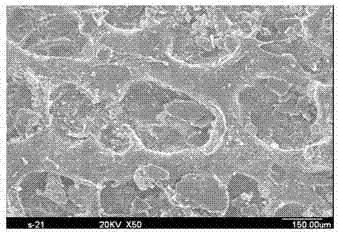

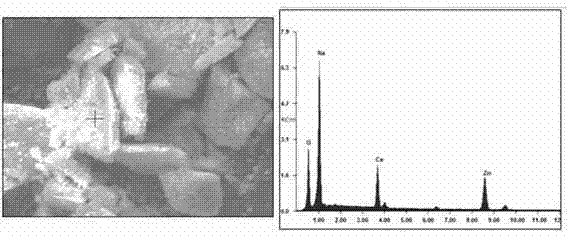

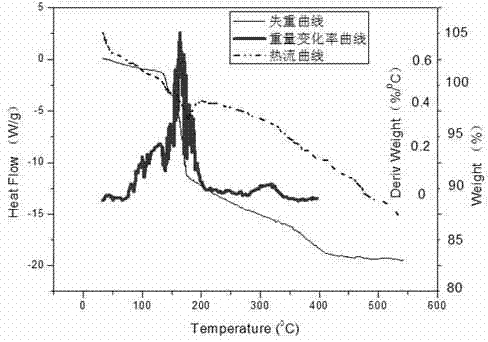

[0022] Add 1000 mL of distilled water to the beaker and heat to 330 K, add 74 mg of calcium hydroxide, stir to make it fully dissolved, add 81 mg of zinc oxide to the calcium hydroxide solution, and continue to react for 12 h under constant stirring to obtain milky white suspension. Cylindrical honeycomb-shaped expanded graphite with a mass of 200 mg, a radius of 2.5 cm and a length of 5 cm was added to the suspension, ultrasonically vibrated at a temperature of 330 K for 24 h, and after standing at a temperature of 293 K for about 12 h, Dry at a temperature of 373 K, take out the expanded graphite and rinse it for 1-2 times, and then dry it in an oven at 323 K for 5 h to make expanded graphite-based CaZn 1.03 (OH) 4.06 2H 2 O / C composite solar chemical heat storage material. Microscopic analysis shows that the material has an amorphous crystal structure and can realize nanoscale composites. Its average dehydration decomposition temperature under normal pressure is about 35...

Embodiment 2

[0024] Add 1000 mL of distilled water to the beaker and heat to 330 K, then weigh 74 mg of calcium hydroxide and add it to the beaker, and stir to make it fully dissolve; weigh 162 mg of zinc oxide and add it to the prepared calcium hydroxide solution, Stir continuously and react continuously for 12 h to obtain a milky white suspension; place a cylindrical honeycomb-shaped expanded graphite with a mass of 200 mg, a radius of 2.5 cm and a length of 5 cm in a beaker, and ultrasonically vibrate at a temperature of 330 K for 24 h; Then the solution was left to stand at a temperature of 293 K for about 12 h, and then the beaker was dried at a temperature of 373 K, and the expanded graphite was taken out and the surface was cleaned. Finally rinsed 1-2 times, and then placed in a 323 k oven to dry for 5 h to make expanded graphite-based CaZn 1.92 (OH) 5.84 2H 2 O / C composite solar energy chemical heat storage material, microscopic analysis shows that the material has an amorphous c...

Embodiment 3

[0026] Add 1000 mL of distilled water to the beaker and heat it to 330K, then weigh 74 mg of calcium hydroxide and add it to the beaker, and stir to make it fully dissolved; weigh 150 mg of nickel oxide and add it to the prepared calcium hydroxide solution, continuously Stir and react continuously for 12 h to obtain a milky white suspension; place powdered expanded graphite with a mass of 200 mg in a beaker, and ultrasonically vibrate for 24 h at a temperature of 330 K; then stand the solution at a temperature of 293 K After about 12 h, the beaker was dried at a temperature of 373 K, the expanded graphite was taken out and the surface was cleaned. Finally rinsed 1-2 times, and then placed in a 323 k oven to dry for 5 h to make expanded graphite-based CaNi 2.12 (OH) 4.24 2H 2 O / C composite solar energy chemical heat storage material, microscopic analysis shows that the material has an amorphous crystal structure and can realize nanoscale composite. Its average dehydration de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com