Wet clutch for connecting power input with output

A wet clutch and power input technology, which is applied in the direction of mechanical drive clutches, clutches, friction clutches, etc., can solve problems such as increased power loss, reduced transmission efficiency of gearboxes, and inability to guarantee the flatness of friction pairs, etc. The effect of row conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

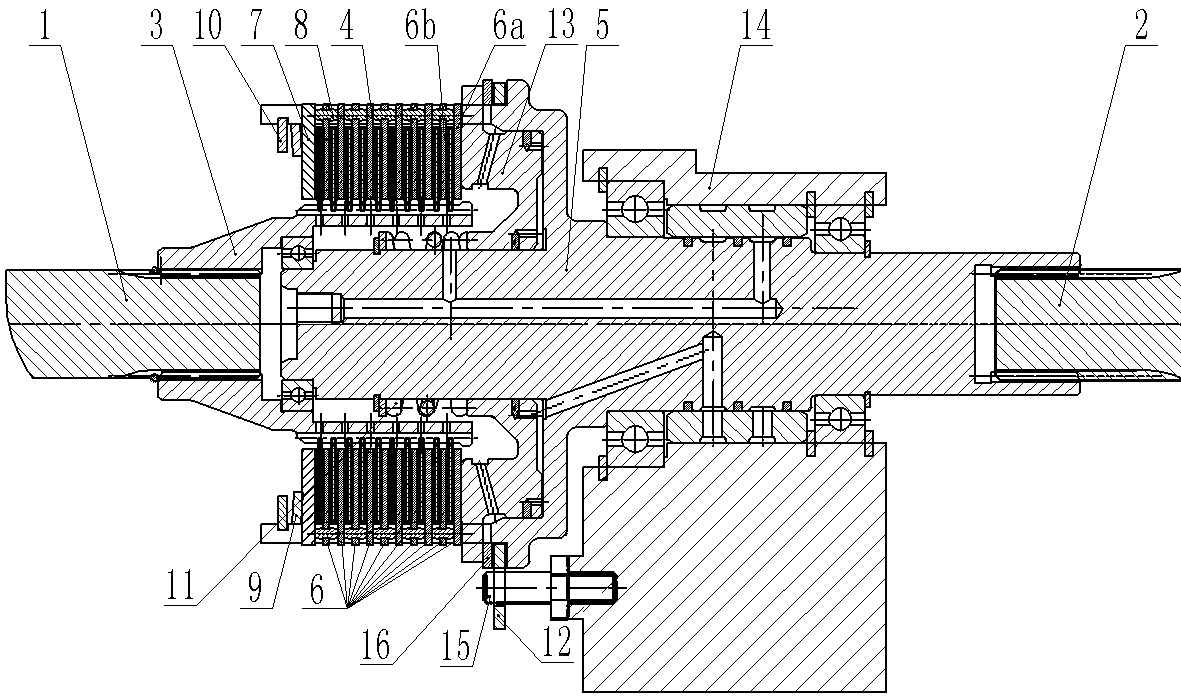

[0014] Example: figure 1 As shown, the wet clutch of the present invention is normally open, and is used to connect the power input shaft 1 and the power output shaft 2 . The engine power is input by the power input shaft 1 after being transmitted by the gearbox, and the adapter sleeve 3 is connected with the power input shaft 1 through a spline. The adapter sleeve 3 is provided with a plurality of active friction plates 4 which are relatively non-rotatable but can move axially. The clutch shaft 5 is supported on the gearbox case 14, on which a plurality of driven steel sheets 6 and pressure bearing plates 7 which are relatively non-rotatable but movable axially are mounted. Four elastic rubber plugs 8 are symmetrically installed on each even driven steel sheet 6b (from the right side), so that an appropriate distance is formed between the odd driven steel sheet 6a and the even driven steel sheet 6b. The active friction plates 4 are inserted between the odd-numbered driven s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com