Rapid cereal digestion method and applications thereof

A technology of grain and ferric tetroxide, which is used in the preparation, sampling, and measuring devices of test samples, can solve the problems of difficult separation and recovery of iron-containing reagents, consumption of large and strong corrosive acids, and high cost of instruments, so as to shorten the sample time. The effect of pretreatment time, reduction of temperature and consumption of concentrated acid, and simplification of digestion steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

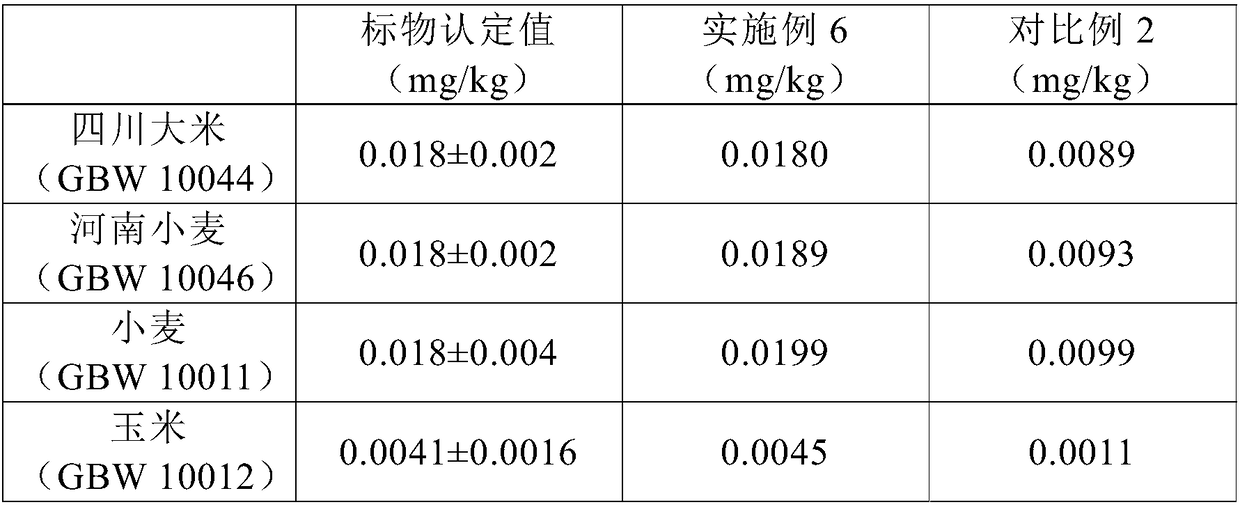

Examples

Embodiment 1

[0037] The mensuration of cadmium content in the rice sample of embodiment 1

[0038] The rice sample was crushed and passed through a 50-mesh sieve, and 0.2 g of the sample (accurate to four decimal places) was weighed as a digestion sample, and placed in a 50 mL centrifuge tube.

[0039] Add 5 mL of 30% hydrogen peroxide, 0.003 g of ferroferric oxide magnetic nanoparticles, and 50 μL of nitric acid. The strength is 3W / mL. After the digestion, a magnet was used to remove the ferroferric oxide magnetic nanoparticles from the solution, and the solution was constant volume to 10 mL to obtain a sample solution to be tested.

[0040] A Cd standard solution with a concentration of 4 μg / L was prepared, and the constant volume solvent was 1% nitric acid.

[0041] Use an atomic absorption spectrophotometer to measure the standard series solutions with concentrations of 0.6μg / L, 1μg / L, 2μg / L, 3μg / L, and 4μg / L, draw a standard curve, and then perform the measurement, and then obtain t...

Embodiment 2

[0043] The mensuration of cadmium content in the wheat core powder sample of embodiment 2

[0044] Weigh 0.2 g of a commercially available wheat core powder sample (accurate to four decimal places) as a digestion sample, and place it in a 50 mL centrifuge tube.

[0045] Add 5 mL of 30% hydrogen peroxide, 0.003 g of ferroferric oxide magnetic nanoparticles, and 50 μL of nitric acid. The strength is 3W / mL. After the digestion, a magnet was used to remove the ferroferric oxide magnetic nanoparticles from the solution, and the solution was constant volume to 10 mL to obtain a sample solution to be tested.

[0046] A Cd standard solution with a concentration of 4 μg / L was prepared, and the constant volume solvent was 1% nitric acid.

[0047] Use an atomic absorption spectrophotometer to measure the standard series solutions with concentrations of 0.6μg / L, 1μg / L, 2μg / L, 3μg / L, and 4μg / L, draw a standard curve, and then perform the measurement, and then obtain the sample to be test...

Embodiment 3

[0049] The mensuration of cadmium content in the rice sample of embodiment 3

[0050] The rice sample was crushed and passed through a 50-mesh sieve, and 0.2 g of the sample (accurate to four decimal places) was weighed as a digestion sample, and placed in a 50 mL centrifuge tube.

[0051] Add 6 mL of 30% hydrogen peroxide, 0.005 g of ferroferric oxide magnetic nanoparticles, and 60 μL of nitric acid. The intensity is 4W / mL. After digestion, use a magnet to separate the ferroferric oxide magnetic nanoparticles from the solution, and dilute the solution to 10 mL to obtain the sample solution to be tested.

[0052] A Cd standard solution with a concentration of 4 μg / L was prepared, and the constant volume solvent was 1% nitric acid.

[0053] Use an atomic absorption spectrophotometer to measure the standard series solutions with concentrations of 0.6μg / L, 1μg / L, 2μg / L, 3μg / L, and 4μg / L, draw a standard curve, and then perform the measurement, and then obtain the sample to be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com