Digestion method and detection method of titanium-rich material

A detection method and technology for titanium-rich materials, which are used in material excitation analysis, preparation of test samples, thermal excitation analysis, etc. Efficient, fast, and simple to test the effect of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

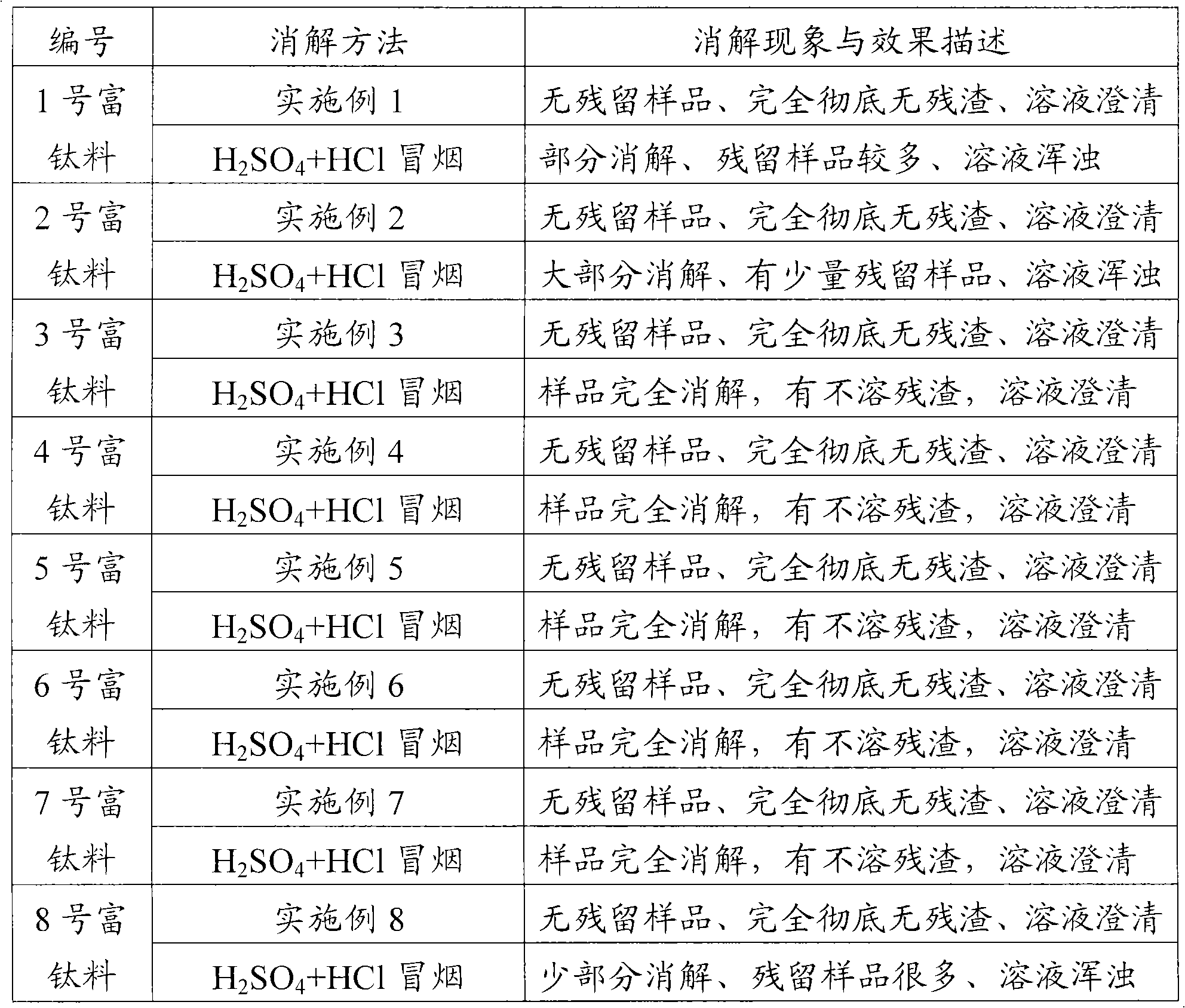

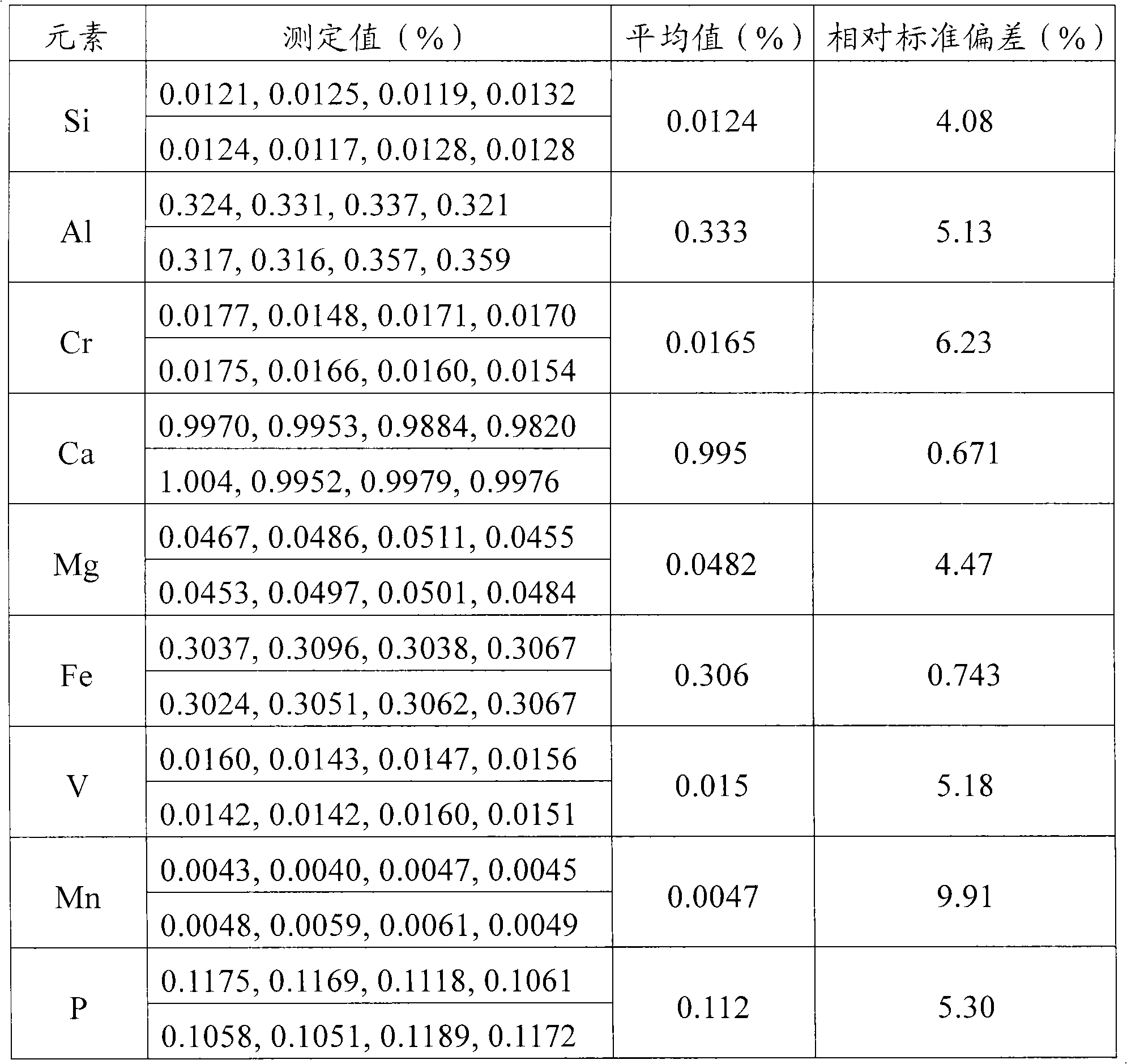

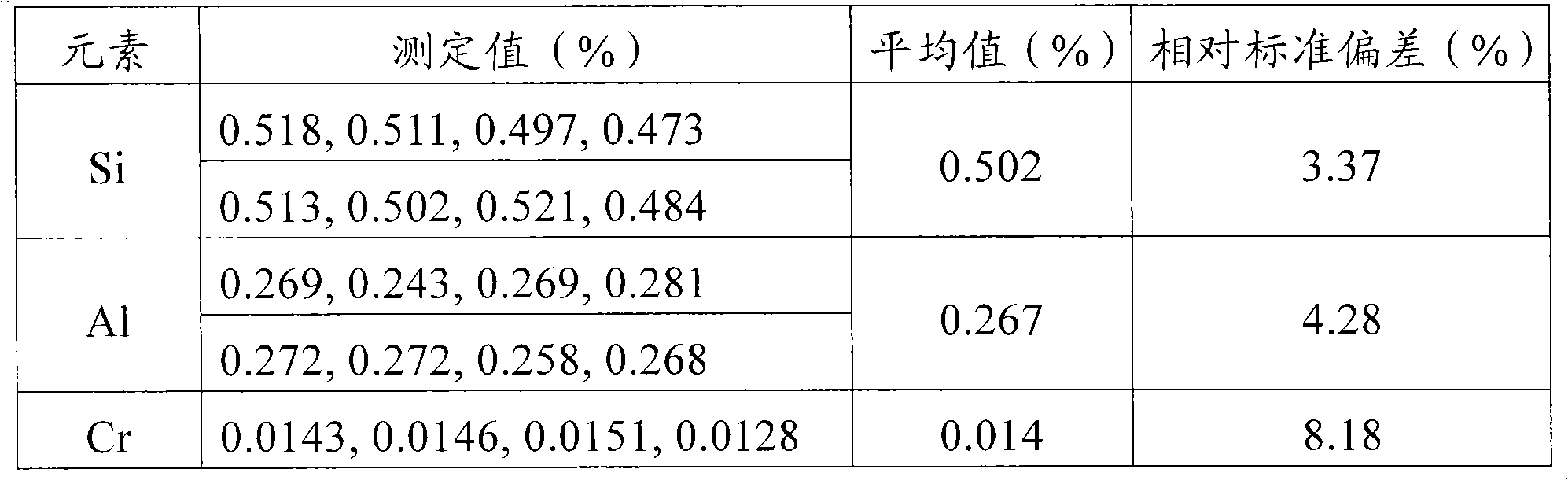

Examples

Embodiment 1

[0024] The acids and reagents used in this example are all high-grade pure. The microwave digestion system used is Mars5 produced by CEM Company of the United States.

[0025] Digestion of titanium-rich materials

[0026] In this example, for TiO 2 The No. 1 titanium-rich material with a content of 97.55% was digested. Weigh 0.2500g of No. 1 titanium-rich material into the microwave digestion inner tank, add 5.0mL of nitric acid with a concentration of 65% to 68% and 1.0mL of hydrochloric acid with a concentration of 36% to 38% dropwise along the tank wall, and shake gently Digestion tank, make the acid fully contact with titanium-rich material at room temperature and pre-react until the liquid level is calm and free of bubbles and NO 2 Brown smoke is generated. After the temperature of the material in the digestion tank is close to room temperature, add 1.0mL of hydrofluoric acid with a concentration of 40% to 47%. In the digestion furnace, connect the temperature and pr...

Embodiment 2

[0035] In addition to using TiO 2 Except that No. 2 titanium-rich material with a content of 92.12% was used instead of No. 1 titanium-rich material, the titanium-rich material was digested in the same manner as in Example 1 and the digestion solution was detected.

Embodiment 3

[0037] In addition to using TiO 2 Except that No. 3 titanium-rich material (high titanium slag) with a content of 75.46% was used instead of No. 1 titanium-rich material, the titanium-rich material was digested in the same way as in Example 1 and the digestion solution was detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com