Substrate surface treatment method, substrate and liquid crystal display panel

A substrate surface and surface treatment technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as poor alignment of liquid crystals, uneven dispersion of surface hydroxyl groups, weak alignment between self-aligned liquid crystals and substrate surfaces, and achieve improved alignment of liquid crystals , Improve the effect of alignment uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

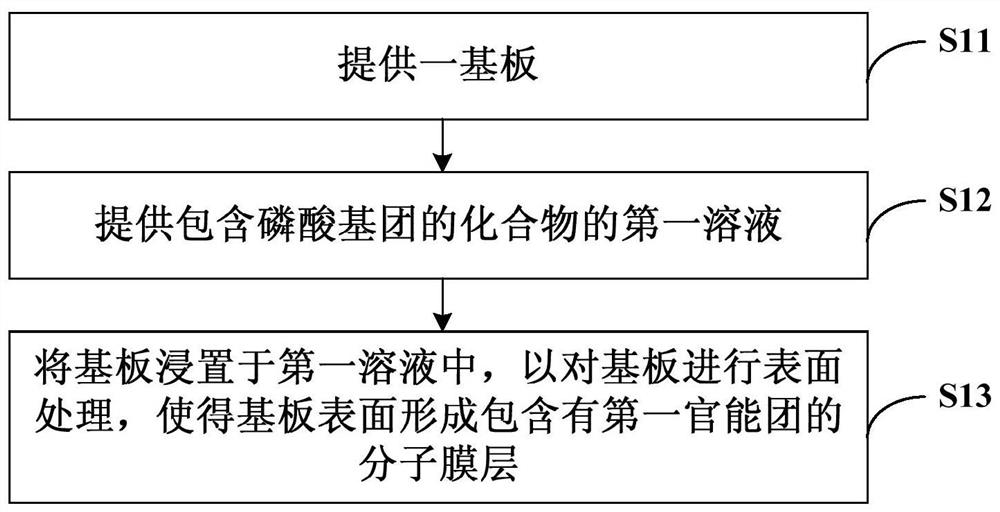

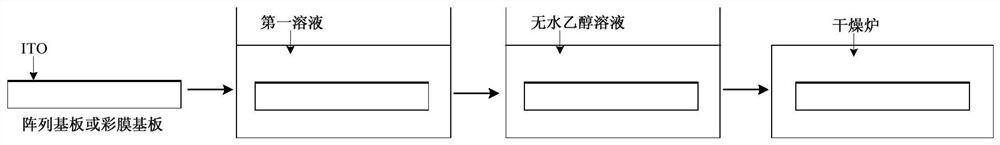

[0016] Such as figure 1 As shown, the first embodiment of the substrate surface treatment method of the present invention includes:

[0017] S11: providing a substrate;

[0018] Wherein, the substrate may be an array substrate or a color filter substrate. The substrate is an oxide substrate, such as a metal oxide substrate (such as an ITO substrate) or a SiO substrate (such as a glass substrate).

[0019] S12: providing a first solution of a compound containing a phosphoric acid group;

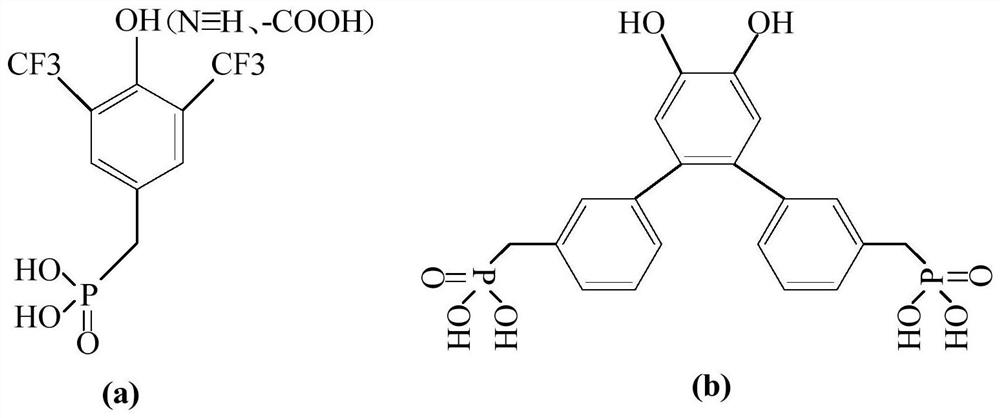

[0020] Wherein, the first functional group of the compound containing a phosphoric acid group is a rigid molecular group containing at least one of a hydroxyl group, an amine group, and a carboxyl group.

[0021] Alternatively, the first solution can be prepared by dissolving the compound containing phosphoric acid groups in an organic solvent. The concentration of the first solution can also be determined according to actual conditions such as the size of the substrate, and no specific de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com