Tobacco material scenting equipment using circulating airflow system

A technology of circulating air flow and tobacco materials, which is applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of short flavoring area, uneven flavoring, and limited throwing space, etc., and achieve reduced crushing rate, convenient operation, Avoid the effect of dissipating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

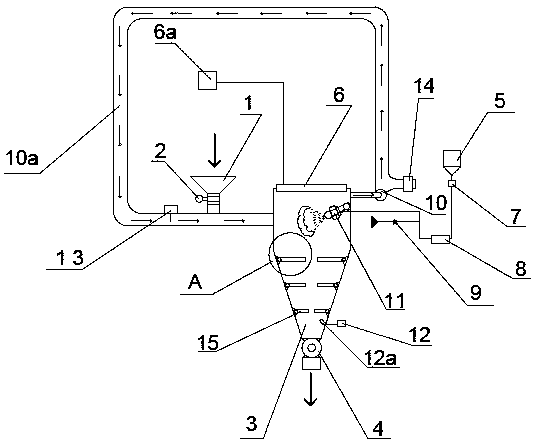

[0022] Such as Figure 1-6 As shown, the tobacco material flavoring equipment using a circulating airflow system includes a shell 3, a circulating air duct 10a connected to the shell 3, and an atomizing device 11 is arranged inside the shell 3, and the atomizing device 11 is connected to an aroma through a delivery pipe. The liquid tank 5, the lower part of the housing 3 is provided with a material outlet, the upper part of the housing 3 is connected to the air outlet of the circulating air duct 10a, and the upper part of the other side is connected to the circulating fan 10 through a pipeline, and the circulating fan 10 The other nozzle is respectively connected with the exhaust damper 14 and the circulating air duct 10a, the circulating air duct 10a is provided with a feed hopper 1, and the casing 3 is a container with a large top and a small bottom, and its inner wall is provided with fixed body 16b, each fixed body 15b is provided with a groove, the groove is movably conne...

Embodiment 2

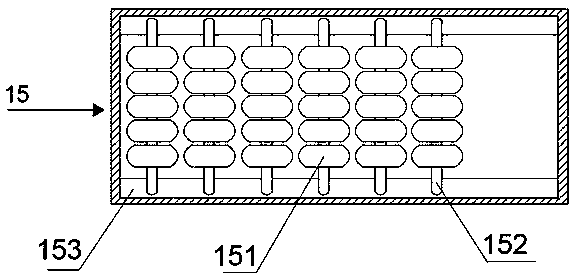

[0024] Such as figure 2As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the middle part of the shell of the baffle 15 is hollowed out, and the inner edge of the baffle 15 is provided with a hollow rolling groove 153, and a rolling rod is movably connected in the rolling groove 153 152, the rolling rod 152 is strung with balls 151, the area formed by the rolling rod 152 and the balls 151 is preferably 70% of the total area of the baffle, and the surface of the ball 151 is provided with a tapered slot hole, when the baffle 15 swings up and down under the influence of magnetic force , the rolling bar 152 in the rolling groove 153 rolls back and forth along the direction in which the baffle plate 15 swings, the balls 151 on the rolling bar 152 rotate freely with the rolling of the rolling bar 152, and a part of the tobacco material goes down along the hem of the baffle plate 15 The other part is squeezed by the rolling rod 152 and the ball 1...

Embodiment 3

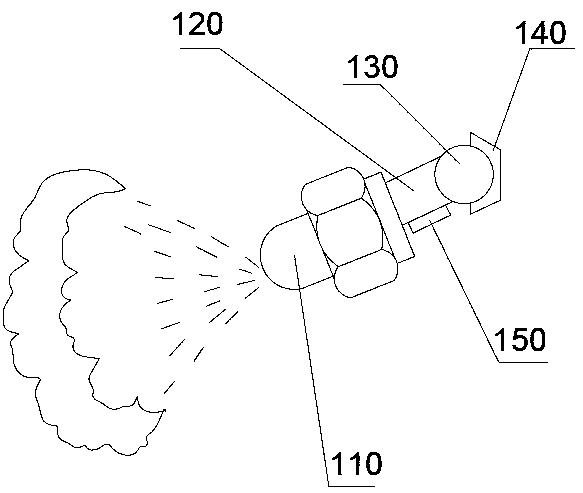

[0027] Such as Figure 1-6 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: a base 140 is provided on the inner wall of the housing 3 on the side opposite to the feed inlet, a groove is provided on the base 140, and the inside of the groove is A rolling ball 130 is movably connected, and an atomizing device 11 is fixedly connected to the rolling ball 130 through a connecting pipe 120. The atomizing device 11 is provided with an atomizing nozzle 110, and a hose 150 is connected to the connecting pipe at the tail end of the atomizing device 11. The hose 150 is connected to the fragrance liquid tank 5 through the delivery pipe, and the atomizing device 11 can swing up and down through the rolling ball 130. When the electromagnet 6 generates magnetic force, the atomizing device 11 is level with the horizontal plane and facing the feeding port of the housing 3 , initially spraying the tobacco material entering the housing 3, so that the tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com