Medicinal material grinding device

A grinding device and medicinal material technology, applied in cocoa, grain processing, food science, etc., can solve the problems of single crushing operation, increase equipment purchase cost, and failure to achieve medicinal powder form, and achieve convenient operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

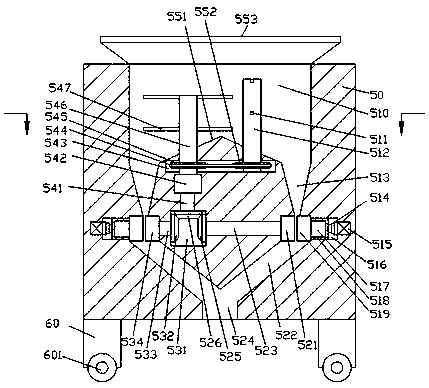

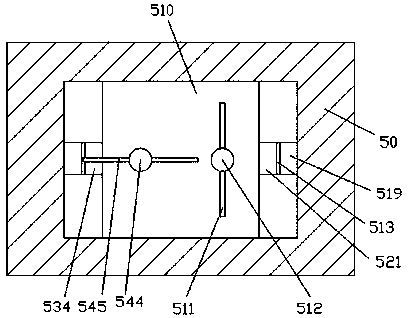

[0015] Combine below Figure 1-3 The present invention will be described in detail.

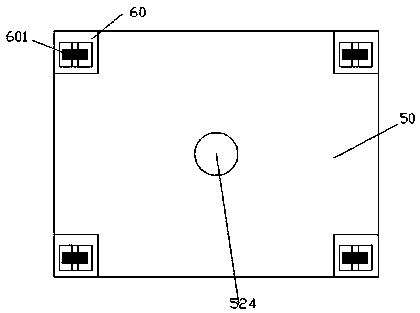

[0016] refer to Figure 1-3 According to an embodiment of the present invention, a medicinal material grinding device includes a box casing 50 fixedly arranged on a stand 60, a rolling wheel 601 is provided at the bottom of the stand 60, and a rolling wheel 601 is arranged on the top end surface of the box casing 50. There is an empty slot 510, and the left and right sides of the inner bottom wall of the empty slot 510 are connected with a first delivery cavity 513, and the inner wall body of the box housing 50 between the first delivery cavity 513 on the left and right sides There is a first rotary bin 543 extending from the middle to the left, and the first motor 542 is fixedly installed on the left side of the inner bottom wall of the first rotary bin 543. The top of the first motor 542 is powered and installed with a second motor 542 extending upward. A rotating arm 546, the first rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com