Foamed cement insulating brick machining device

A processing device and technology of foamed cement, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low cutting accuracy and labor, and achieve the effects of reducing defective products, simple operation, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

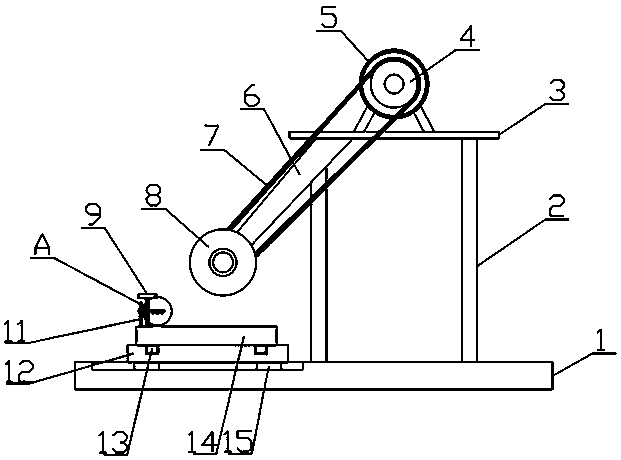

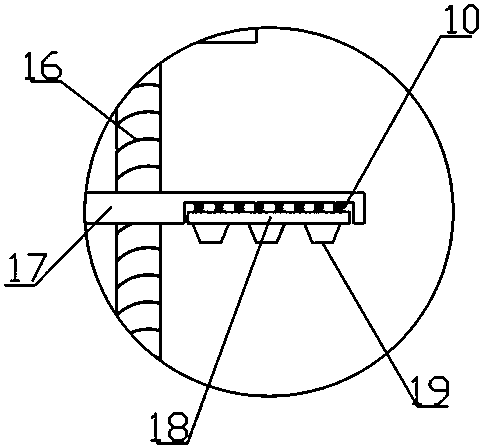

[0014] refer to Figure 1-2 , a foam cement insulation brick processing device, comprising a base 1, the upper end of the base 1 is fixedly connected with two support rods 2, the upper ends of the two support rods 2 are jointly provided with a mounting plate 3, and the upper end of the mounting plate 3 is fixedly connected with The driving motor 5 is fixedly connected with the driving wheel 4 at the end of the output shaft of the driving motor 5, pushes the fixed plate 12, the first slider 15 moves, then pushes the storage plate 14, the second slider 13 moves, and then turns on the switch of the driving motor 5 , the drive motor 5 rotates to drive the driving wheel 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap