Desktop 3D printer with novel wire feeding mechanism

A technology of 3D printer and wire feeding mechanism, which is applied in the field of 3D printing, and can solve the problems of insufficient spray nozzle stability, poor printing quality, and large wire feeding resistance, and achieve stable feeding, improved effective contact, and low wire feeding resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

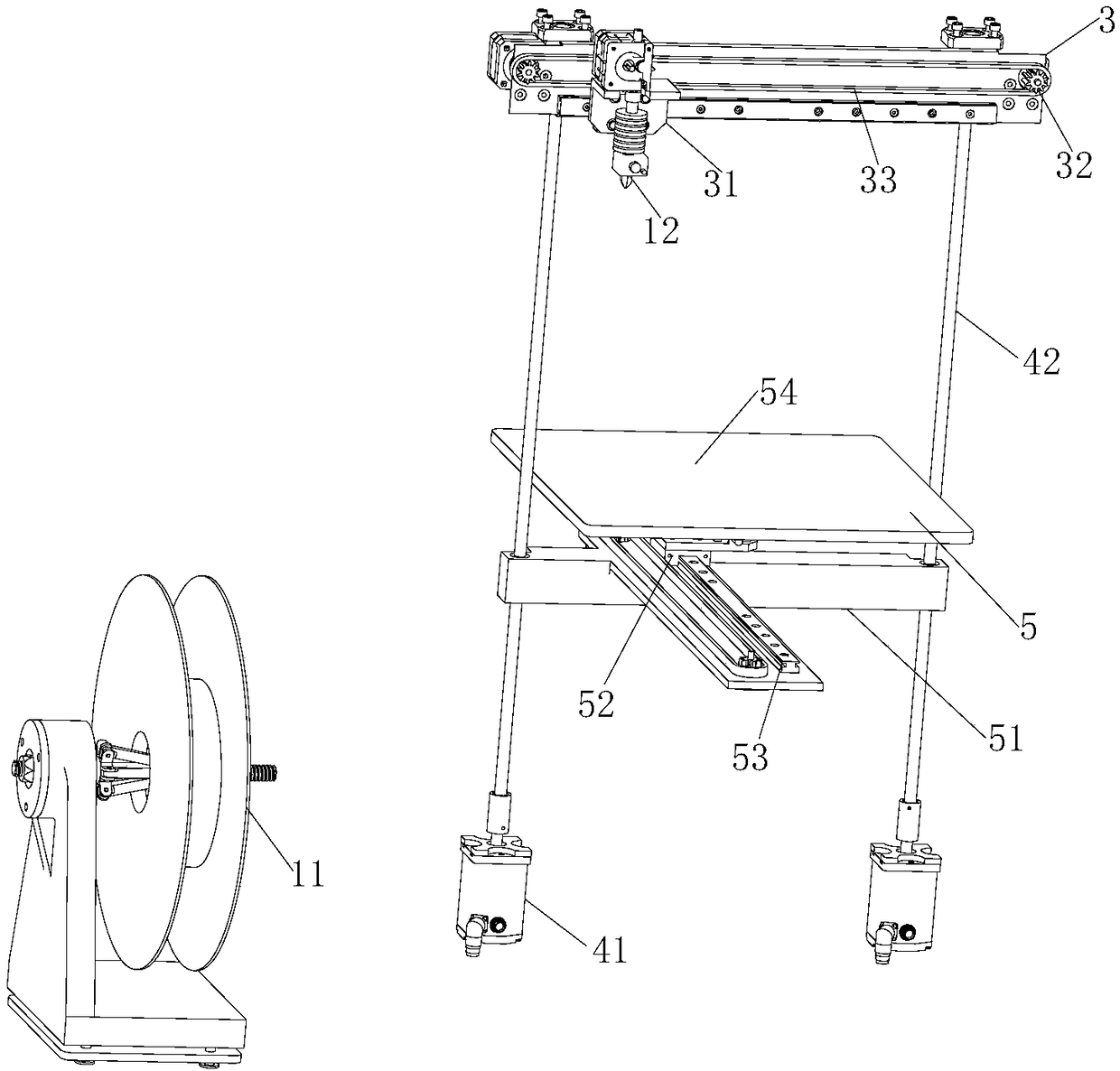

[0024] combine Figure 1 to Figure 6 As shown, this embodiment is a detailed description of the structure of a desktop 3D printer with a new wire feeding mechanism.

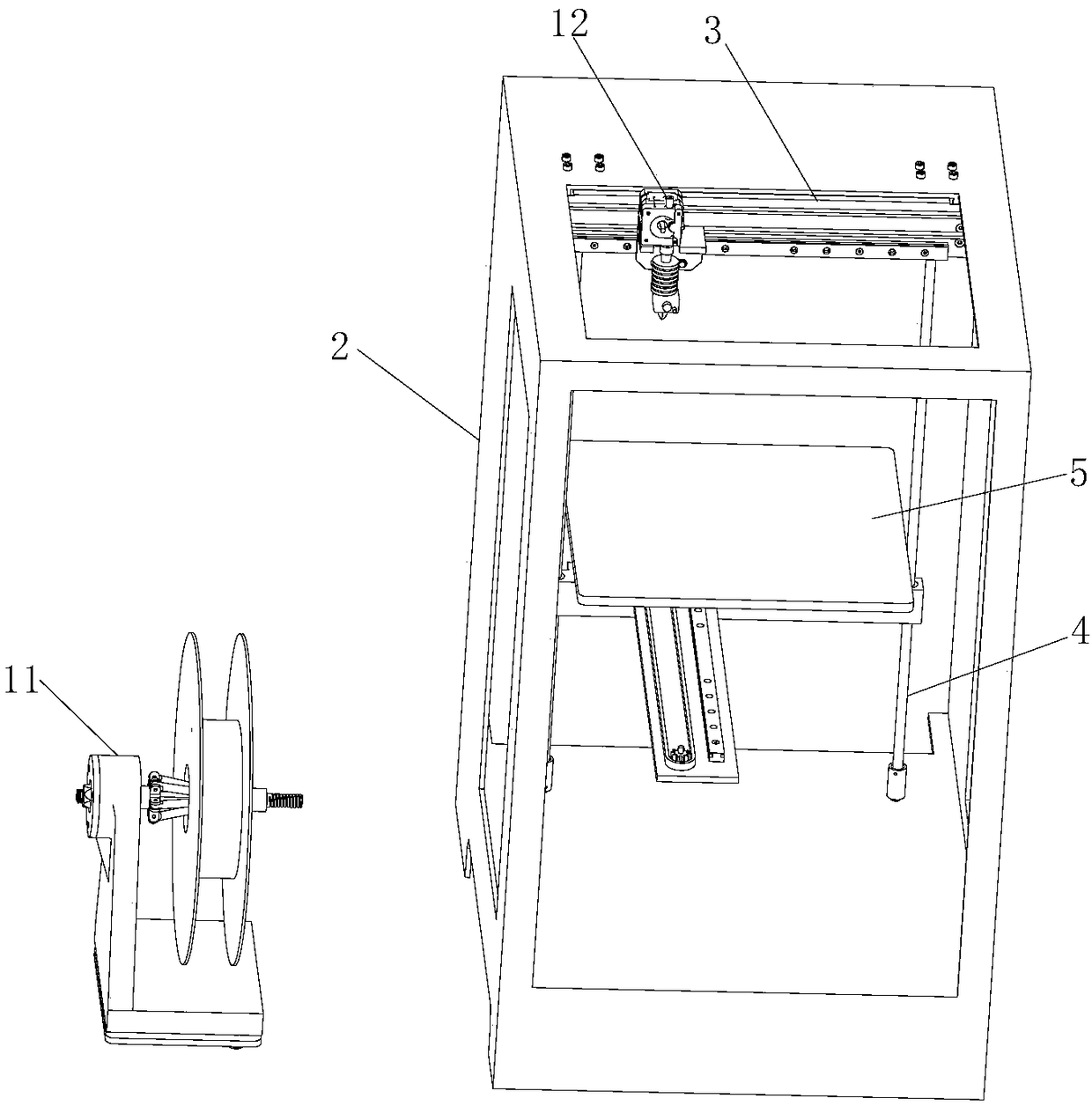

[0025] Such as figure 1 and figure 2 As shown, a desktop 3D printer with a new type of wire feeding mechanism specifically includes a wire feeding mechanism 1 , a slide rail mechanism 3 , a screw feeding mechanism 4 , a horizontal movement mechanism 5 and a printer support mechanism 2 . The printer support mechanism 2 is used as the shell support of the 3D printer. The wire feeding mechanism 1 includes an external wire feeding mechanism 11 and an internal wire feeding mechanism 12 , the external wire feeding mechanism 11 is fixedly installed on the outside of the printer or near the printer through a mounting plate, and the internal wire feeding mechanism 12 is arranged on the slide rail mechanism 3 . Lead screw feed mechanism 4 is fixed on the printer supporting mechanism, and comprises two vertical screw ma...

Embodiment 2

[0031] This embodiment is an illustration of the structural optimization design of the external wire feeding mechanism of the desktop 3D printer in Embodiment 1.

[0032] combine Figure 4 As shown, the wire reels used by desktop 3D printers mainly have specifications such as 0.5kg and 1.0kg, and the inner diameters of wire reels with different weights are inconsistent. The adjustable external wire feeding mechanism 11 is designed to adapt to different inner diameters, which can reduce wire feeding friction Resistance, the support shaft 103 and the bearing 111 provided by the external wire feeding mechanism 11 have a self-lubricating function, which avoids the problem of broken wires in the nozzle caused by insufficient wire material, resulting in product defects.

[0033] As one of the key structures of the external wire feeding mechanism, the support shaft is the main force-bearing part. The material is ordinary carbon steel Q200. The support shaft is not directly connected ...

Embodiment 3

[0036] This embodiment is an illustration of the structural optimization design of the internal wire feeding mechanism of the desktop 3D printer in Embodiment 1.

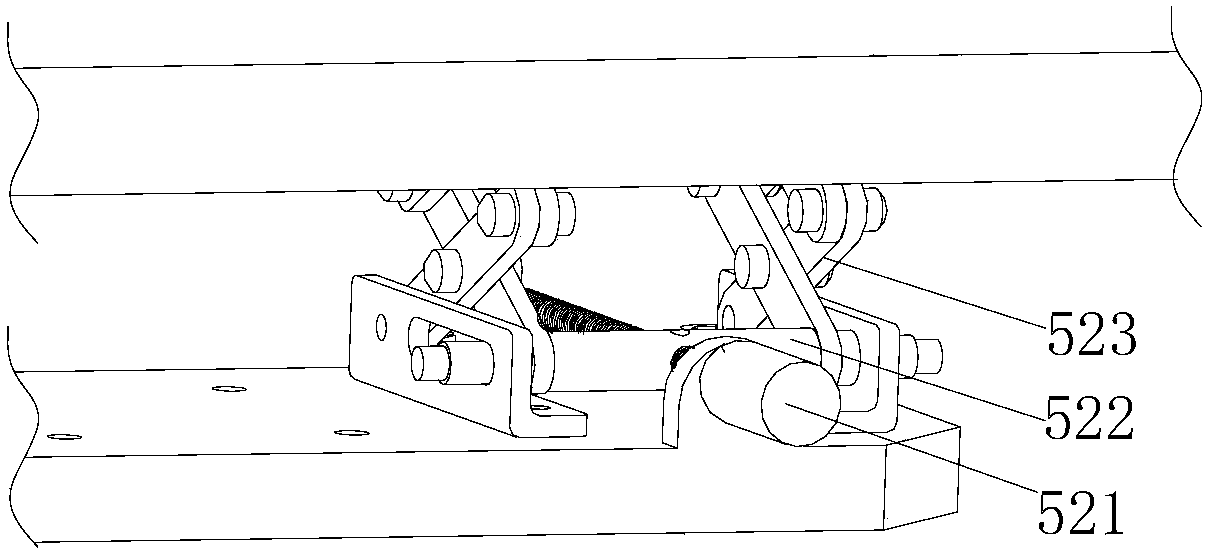

[0037] combine figure 1 , figure 2 and Figure 6 The internal wire feeding mechanism 12 shown is the main structure of the heating extrusion device. The wire feeding motor 201 uses a stepping motor to drive the active wire feeding wheel 213 to rotate, pushes the solid wire through the upper teeth of the wire feeding gear, and cooperates with the driven wheel to move The wire is sent to the wire feeding tube and enters the heating device. There are three kinds of extrusion methods: piston type, sliding vane pump type, and plunger pump type. Considering the performance of the device and the complexity of the design, the nozzle 208 is a piston type extrusion device. This design requires low control accuracy, small overall quality, and difficult processing. Small size, low processing cost and short development cycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com