Horizontal stabilizer bar assembly with quick and adjustable roll stiffness of FSAE racing car and adjusting method thereof

A technology of stabilizer bars and stiffness, which is applied in the direction of racing cars, motor vehicles, vehicle springs, etc., can solve the problems of increasing the length and quality of the main body plate, uneven force on the tie rods, and low adjustment efficiency, so as to reduce the mass of the assembly, Reduce disassembly and assembly processes and improve adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

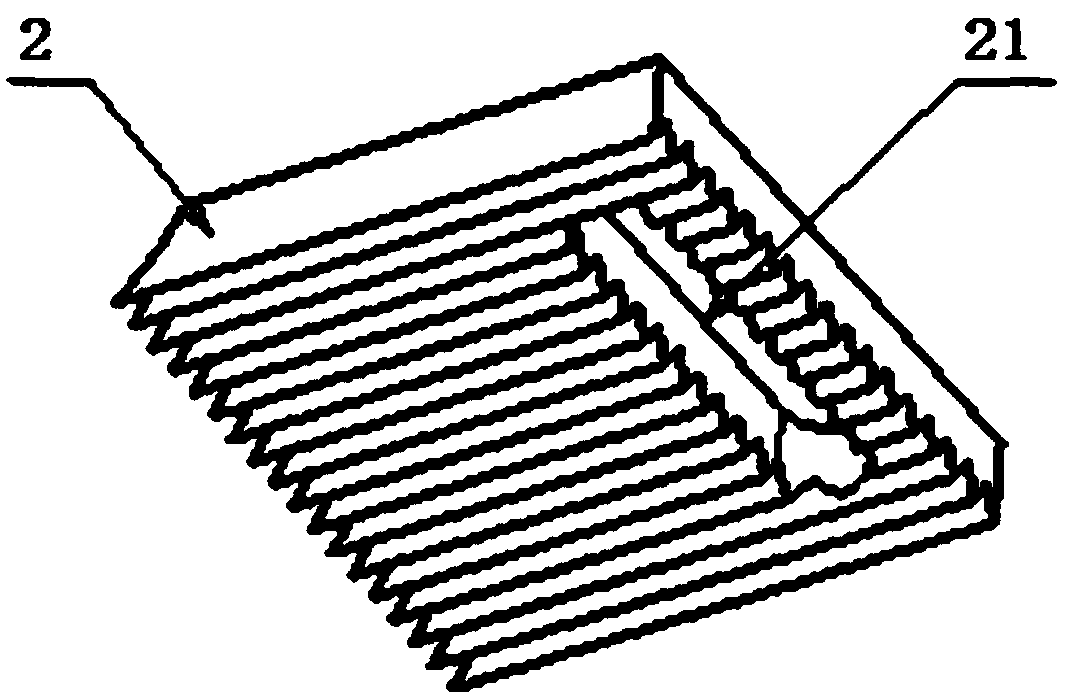

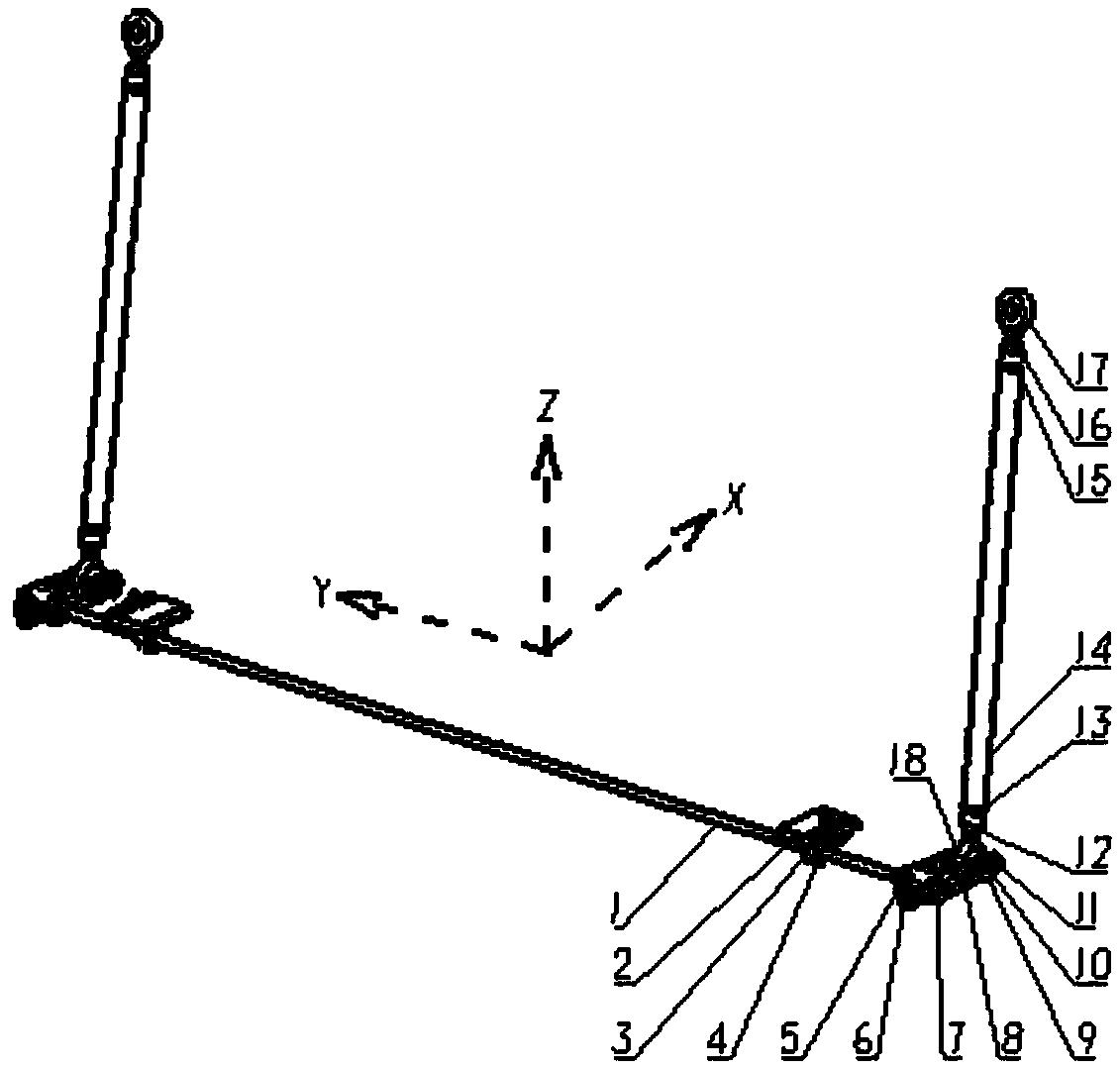

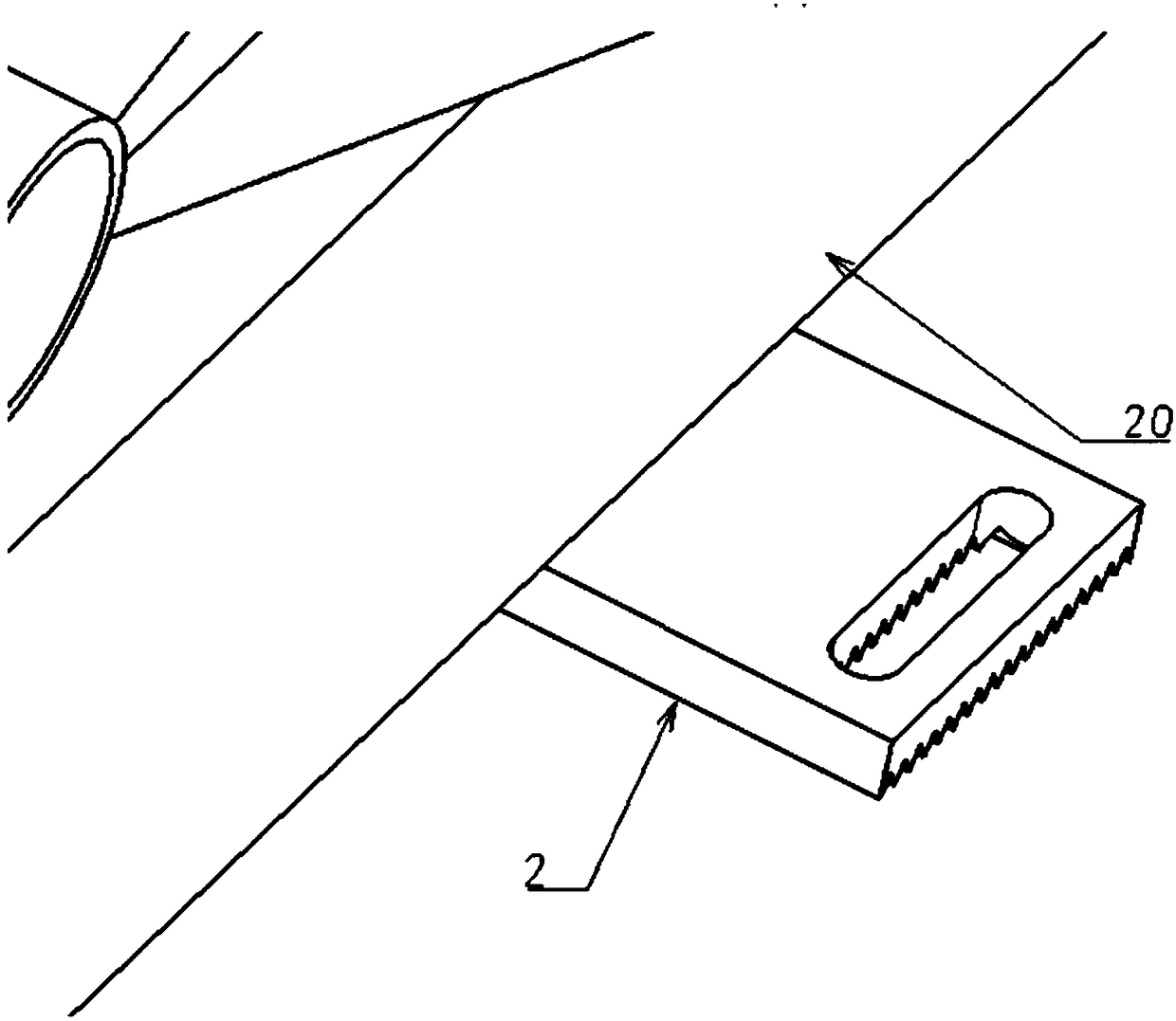

[0034]The meaning of each label in the attached drawings: 1- torsion bar spring, 2- lug seat, 3- lug, 4- bushing, 5- lock nut, 6- grade C full thread hex head bolt, 7- terminal , 8-adjusting arm, 9-plug bolt, 10-spherical washer, 11-external thread right-handed rod end joint bearing, 12-right-handed hex nut, 13-right-handed rod end bearing thread sleeve, 14-tie rod, 15 -Threaded sleeve for left-handed rod end bearing, 16-Left-handed hex nut, 17-External threaded left-handed rod end joint bearing, 18-Class C flat washer, 19-Suspension rocker, 20-Frame, 21-Guide groove, 22- Adjusting hole, 23-bearing hole, 24-end face.

[0035] Such as Figure 1 to Figure 11 As shown, this embodiment provides a FSAE racing car roll stiffness quickly adjustable stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com