Concrete silo top plate structure and construction method thereof

A concrete and roof technology, applied in building types, buildings, large-capacity bulk material storages, etc., can solve the problems of long period of erection and dismantling of formwork systems, high working surface height, and high safety risks, so as to reduce construction costs, The effect of saving costs and avoiding security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

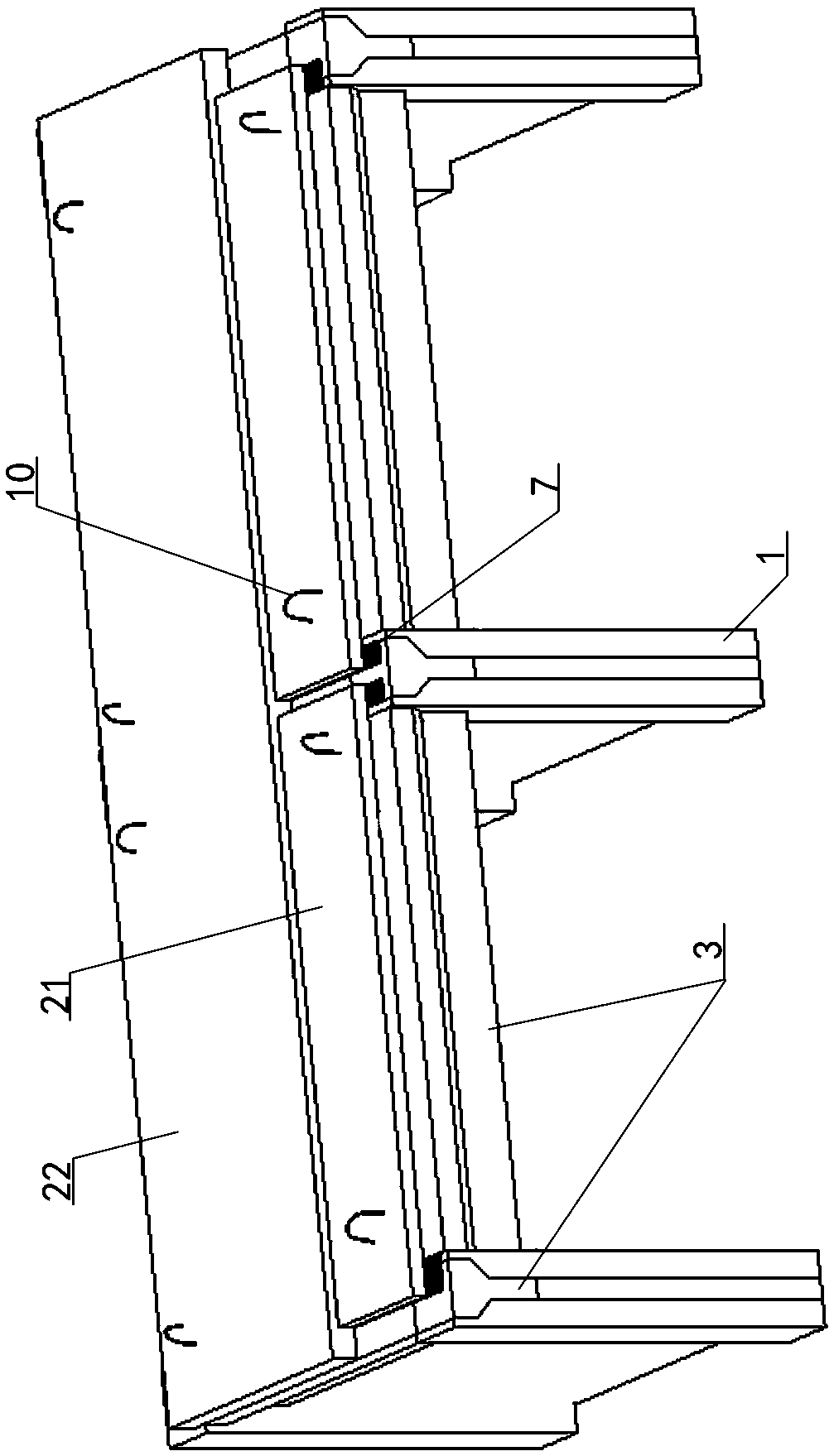

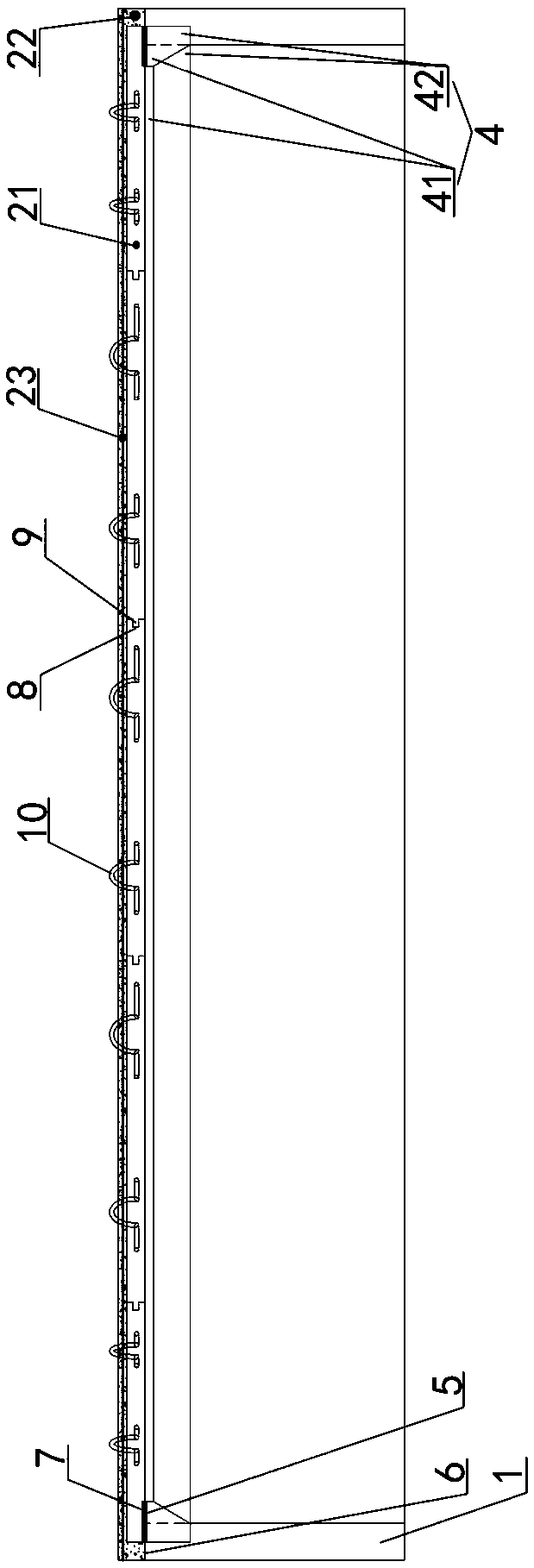

[0035] Embodiment one sees Figure 1-2 As shown, a concrete silo roof structure includes a silo wall 1 and a roof 2. The roof covers the silo and is fixedly connected to the top of the silo wall.

[0036] The roof includes a prefabricated lower part 21 and a cast-in-place upper part 22, the prefabricated lower part is a prefabricated reinforced concrete slab, the size of the prefabricated lower part 21 is smaller than the size of the silo, and the prefabricated lower part 21 is lapped on the silo wall 1 to cover the silo The inner space of the cast-in-place upper part 22 is a cast-in-place concrete layer laid with steel mesh sheets 23, the outer contour size of the cast-in-place upper part is equal to the outer contour size of the silo, and the cast-in-place upper part is cast-in-place on the upper side of the prefabricated lower part, Together with the prefabricated lower part it forms the roof.

[0037] The concrete silo roof structure also includes roof supporting corbels ...

Embodiment 2

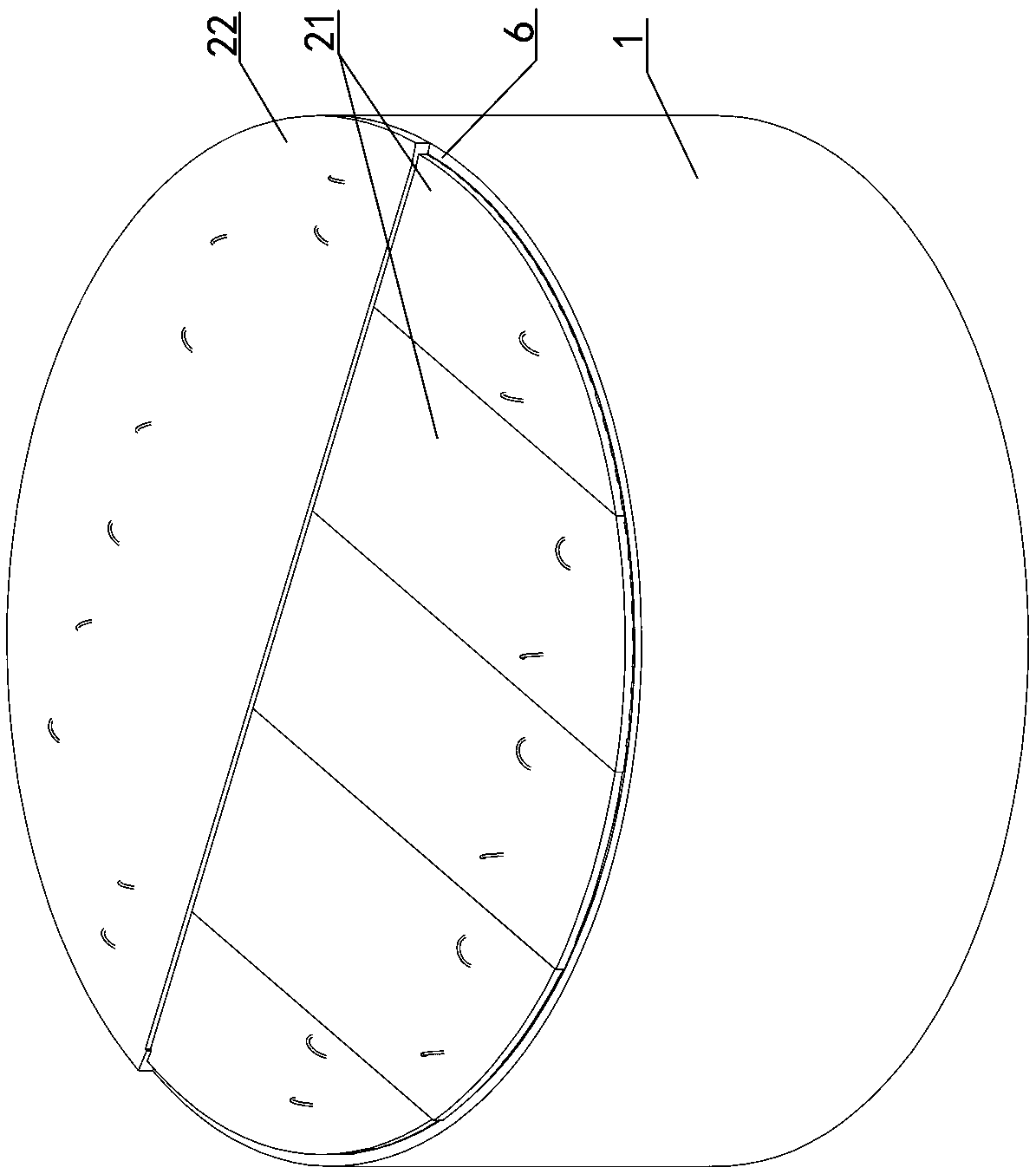

[0042]Embodiment two see Figure 3-4 As shown, the difference from Embodiment 1 is that the silo is a circular silo, the silo wall is a ring, the roof supporting corbels also form a ring along the silo wall, and the prefabricated lower part is a set of strips Shaped prefabricated slabs, arranged in the same direction, the width of the strip prefabricated slabs is the same, the edge of the strip prefabricated slab is lapped on the roof support corbel, and the edge shape of the strip prefabricated slab is set along the roof support corbel to match the roof support The arc that matches the arc of the corbel.

[0043] The roof supporting bracket is located on the top inner side of the warehouse wall 1, and the top supporting bracket is a second bracket 4. The cross section of the second bracket 4 is wide at the top and narrow at the bottom, and the second bracket 4 includes from bottom to top. The second upper part 41 and the second lower part 42, the second upper part 41 has a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com