Intermediate infrared high-reflection optical element test apparatus and test method based on optical parameter oscillator

A technology of optical components and optical parameters, which is used in optical instrument testing, machine/structural component testing, measuring devices, etc., can solve the problems of complex structure of deuterium fluoride chemical lasers, inconvenient testing of optical components, and high operating costs, and achieves the use of The effect of low cost, high reliability, high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

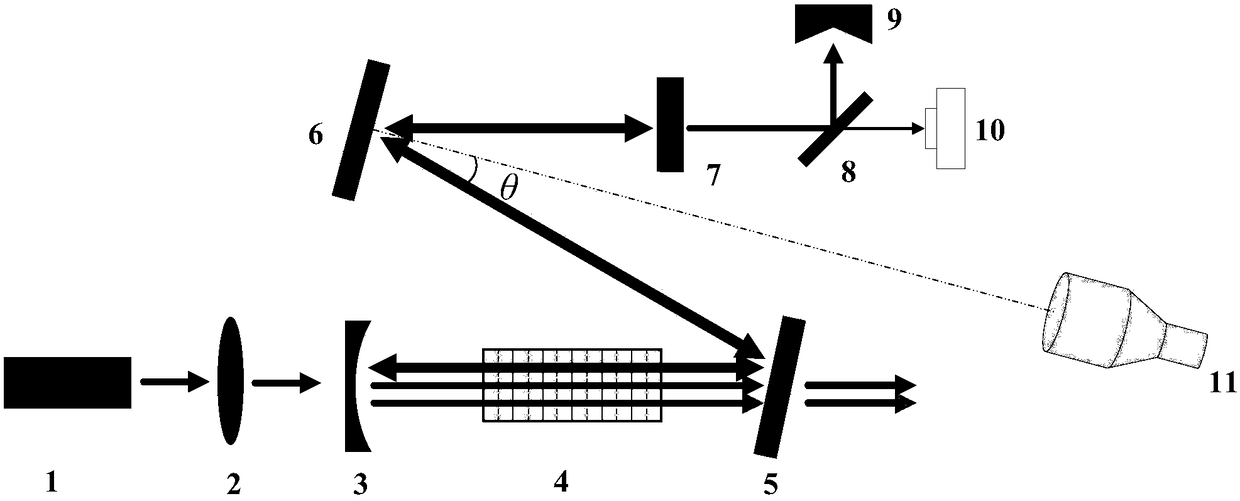

[0037] see figure 1 , the mid-infrared high-reflection optical element testing device based on an optical parametric oscillator provided by the present invention includes a near-infrared fiber laser 1, a pump coupling optical system 2, a high-reflection cavity mirror 3, a nonlinear frequency conversion crystal 4, and a dichroic mirror 5 , a mid-infrared high-reflection optical element 6 to be tested, a coupling output mirror 7, a mid-infrared spectroscope 8, a power meter 9, a mid-infrared camera 10, and a monitoring system 11; wherein the high-reflection cavity mirror 3, the dichroic mirror 5, the to-be-tested The mid-infrared highly reflective optical element 6 and the outcoupling mirror 7 form a resonant cavity of a closed-cavity op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com