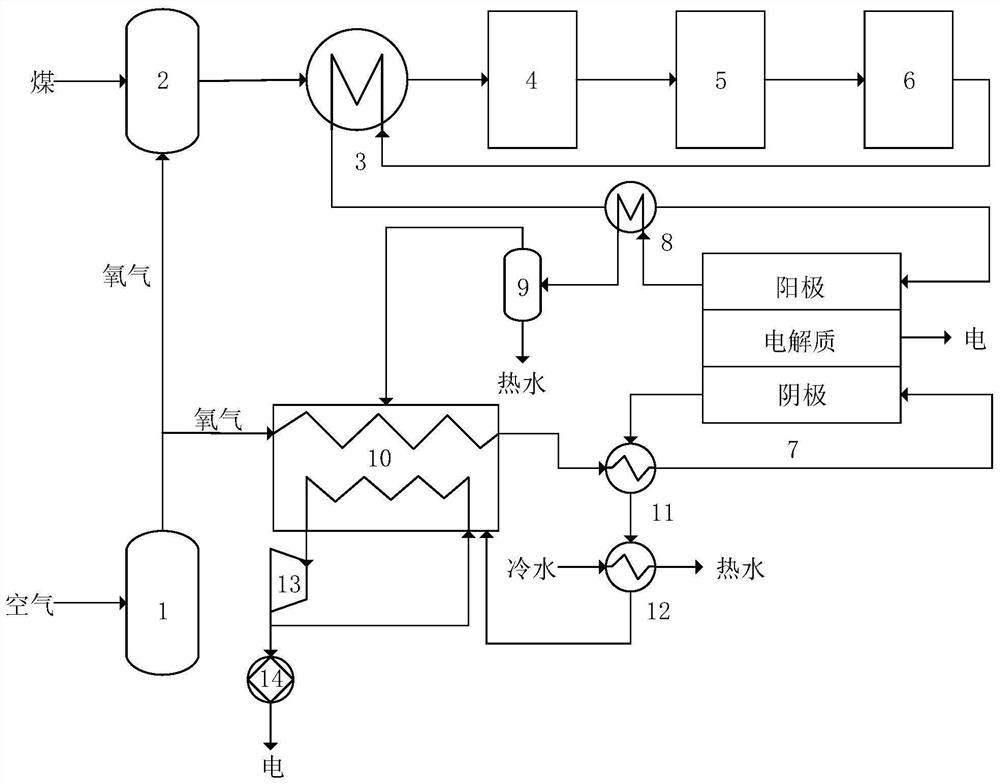

Integrated coal gasification solid oxide fuel cell-steam turbine combined power generation system and process

A solid oxide, fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of natural gas and coke oven gas not conforming to national conditions, etc., to improve power generation efficiency and energy utilization, Avoid corrosion and leakage problems and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) 41750Nm 3 / min air passes into the air separation plant 1, and oxygen and nitrogen are separated in the air separation plant 1, and the oxygen is divided into two strands by the oxygen output pipeline of the air separation plant 1, one (flow 350Nm 3 / min) into the gasifier 2 and 0.6t / min coal for coal gasification reaction to generate synthesis gas, the temperature of the synthesis gas output from the gasification furnace 2 is 800-900°C, the composition of the synthesis gas is CO: 30-70V%, h 2 : 5~30V%, CO 2 : 5~15V%, H 2 O: 0~15V%, CH 4 : 0~5V%, H 2 S: 0-8V%. The synthesis gas enters the first heat exchanger 3 through the high-temperature gas inlet of the first heat exchanger 3 for heat exchange, and the temperature drops below 100°C, then is output from the high-temperature gas outlet of the first heat exchanger 3 and enters the electrostatic precipitator 4 , so that the particle content is less than 200mg / Nm 3 ; Then pass into the desulfurization device 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com