Magnetofluid vector control system based on superconducting magnetic field

A technology of vector control and strong magnetic field, applied in ship propulsion, ship parts, ships, etc., can solve the problems of large mechanical noise, large space occupation, large turning radius, etc., and achieve the effect of no mechanical noise and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

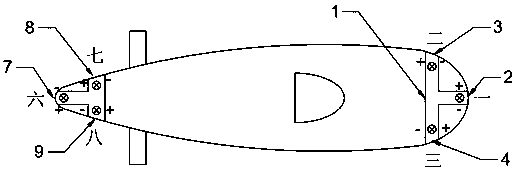

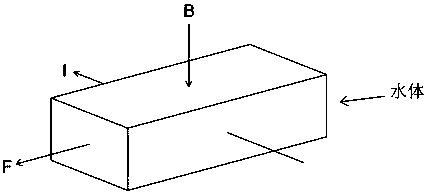

[0030] Such as Figure 1~Figure 18 As shown, the present invention includes a five-way seawater duct 1, a magnetic pole 12, an electrode 13, a high-power DC generator, a fan blade 17, a scraper 18, a drum-shaped gear 21, a cat-ear cavity 29, and an isolation grid 22, Five-way seawater ducts 1 are arranged horizontally at the fore and aft parts of the submarine, and the two five-way seawater ducts 1 include duct one 2, duct two 3, duct three 4, duct four 5, and duct five 6 , Duct 6 7, Duct 7 8, Duct 8 9, Duct 9 10, Duct 10 11. There are 10 ducts in total. Duct 1 and Duct 6 are on the same axis as the center of gravity O of the submarine and parallel to the axis of the main body of the submarine. , Ducts 2 and 3 are coaxial and set horizontally; Ducts 7 and 8 are coaxial and set horizontally. Ducts 2 and 3 and Ducts 7 and 8 are equidistant from the center of gravity of the submarine; Straight setting, duct nine, ten coaxial, vertical setting, each duct opening coincides with th...

Embodiment 2

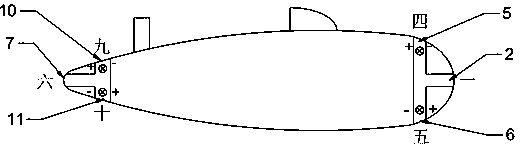

[0035] Such as Figure 1~Figure 18As shown, the present invention includes a tee-shaped seawater channel, a magnetic pole 12, an electrode 13, a high-power DC generator, fan blades 17, a scraper 18, a drum-shaped gear 21, a cat-ear cavity 29, and an isolation grid 22. The three-way seawater culverts are set horizontally at the fore and aft parts of the warship, and the two three-way seawater culverts include 6 culverts, namely, channel 1, channel 2, channel 3, channel 4, channel 5, and channel 6. Ducts 1 and 4 are on the same axis as the center of gravity O of the ship and parallel to the main axis of the ship. Ducts 2 and 3 are coaxial and set horizontally; Ducts 5 and 6 are coaxial and set horizontally. Ducts 5 and 6 are equidistant from the center of gravity O of the ship; each duct opening is consistent with the hull of the ship, and each duct is provided with a pair of magnetic poles 12 and a pair of electrodes 13 near the duct opening. The electrode 13 is arc-shaped, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com