Unmanned aerial vehicle charging pile

A technology of unmanned aerial vehicles and charging piles, applied in the field of unmanned aerial vehicles, can solve the problems of affecting work efficiency, limited power, increase costs, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

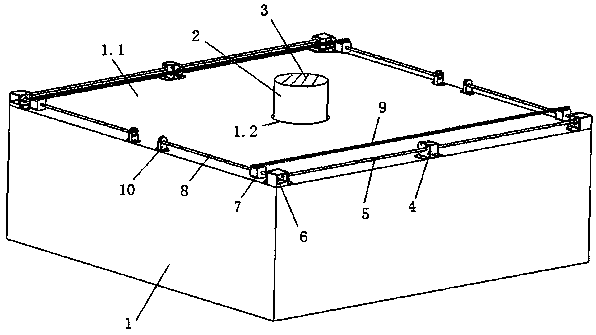

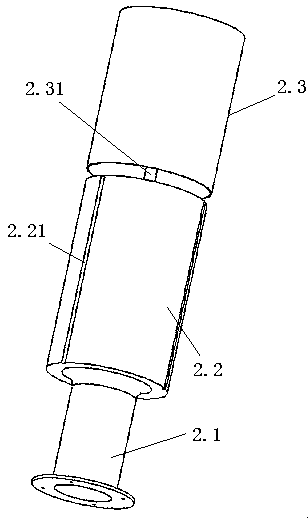

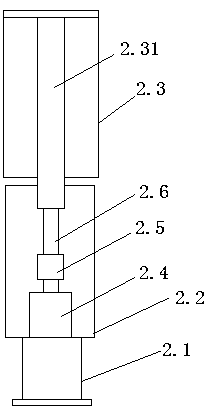

[0032] At present, drones basically rely on batteries for power supply. The battery can provide limited power at one time, and the battery life is low. It is necessary to prepare multiple batteries at the same time and control the drone to land every once in a while to replace the battery, enhance its battery life, and operate The process is cumbersome, and the UAV needs to disassemble and assemble the battery many times during the mission, which not only affects the work efficiency, but also easily damages the electronic components and rack of the UAV, which increases the cost. Although wireless charging piles are used to charge UAVs nowadays, the current UAV charging piles have a complex structure, and it is difficult to automatically locate the charging position of the UAV, and the wireless charging device is exposed outside, which is easily affected by the external environment. The impact of the battery is damaged, which affects the service life of the wireless charging dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com