Dyeing and wrinkling synchronized process for wrinkling cloth

A crepe cloth and process technology, applied in the field of synchronous dyeing and wrinkling process, can solve the problems of large auxiliary cost and sewage, long working hours, complicated process, etc., and achieve the effect of strong three-dimensional effect, simple process and excellent color rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] (1) Use the unwinder to unroll the wrinkled gray cloth, and sew 7-8 pieces of the unrolled gray cloth. The total length of the wrinkled gray cloth after the seam is controlled at 350-450m. The photo of the cloth gray cloth is as figure 1 shown.

[0041] (2) Pound the crepe gray cloth after seaming, determine the actual weight of the seam gray cloth, and determine the amount of dyes and auxiliary agents in subsequent steps (3) and (4) by proofing.

[0042] (3) Reactive dyeing: Send the measured seam head gray cloth into the Fong's air cylinder. During active dyeing, control the rotation speed of the cloth lifting wheel in the dyeing cylinder to 360m / min. During the subsequent dyeing process, control the total power of the fan in the Fong's air cylinder. 25-35%.

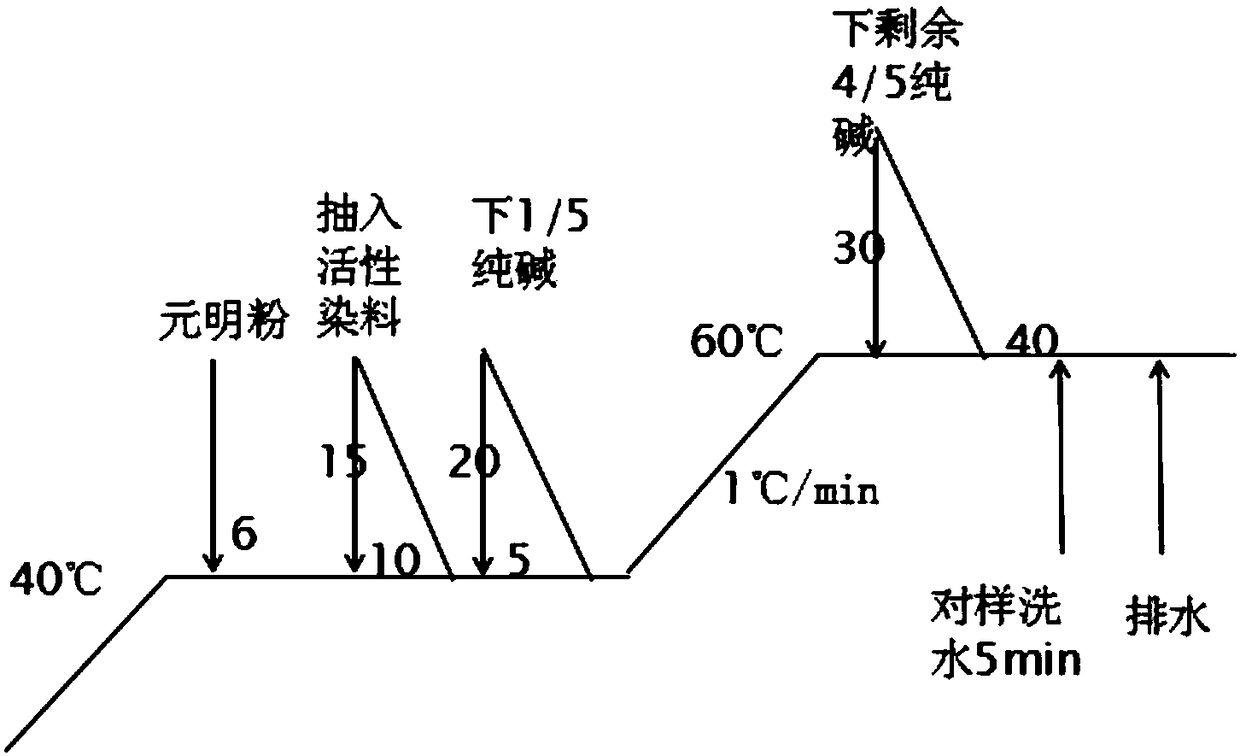

[0043] Such as figure 2 As shown, add process water into the dye vat and heat up to 40°C, add process amount of dissolved sodium sulfate, run for 6 minutes, so that the cloth surface is evenly soaked with so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com