Multi-carbon battery

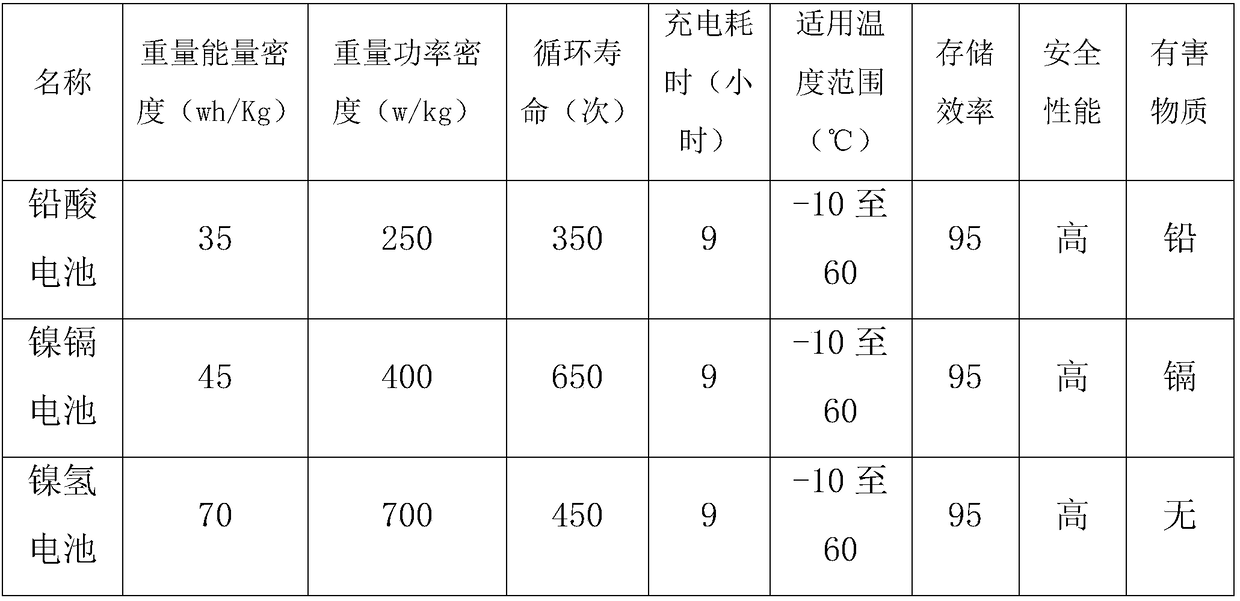

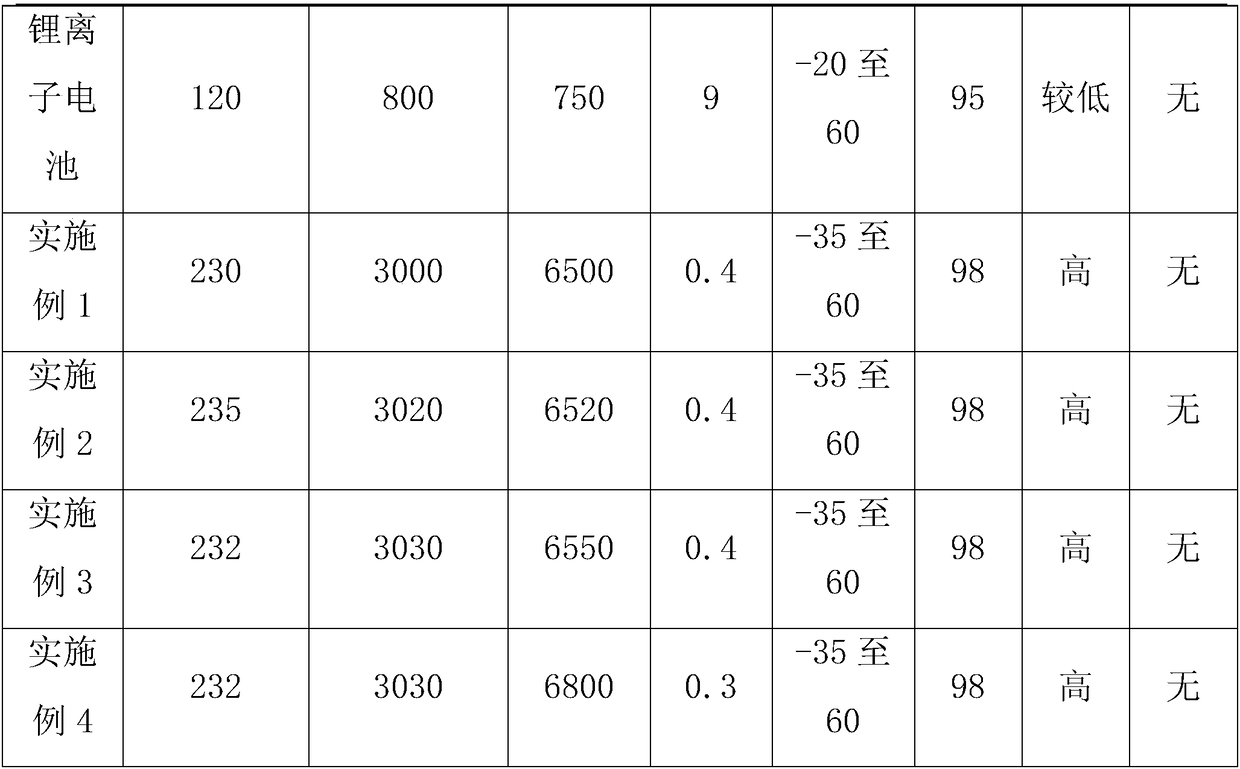

A technology of carbon battery and porous activated carbon, which is applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the problems of long charging time and short cycle life of batteries, and achieve super strong discharge capacity at large currents, small process losses, and energy conversion high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

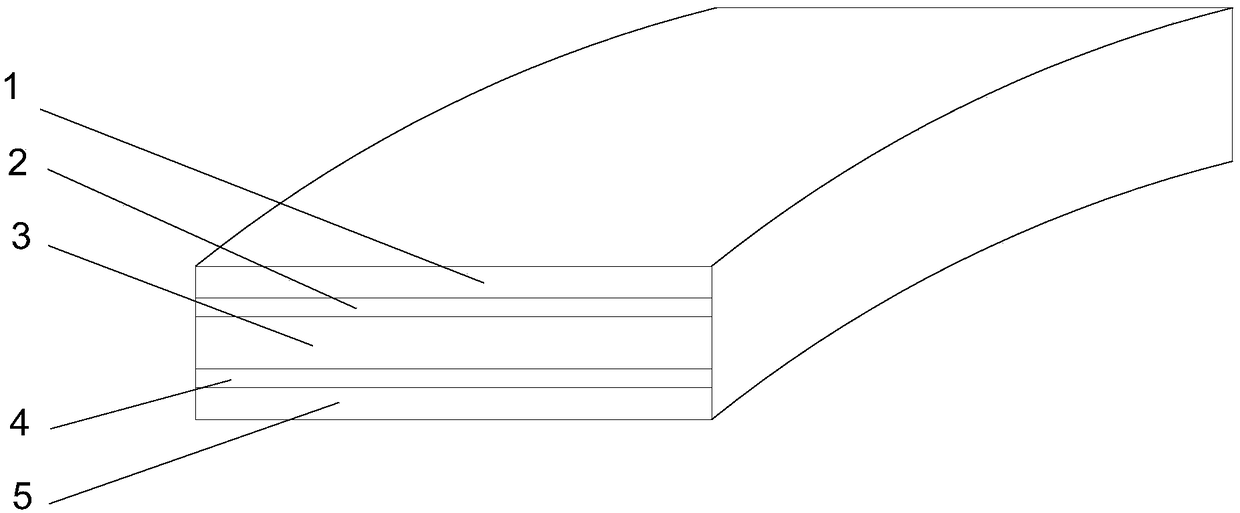

[0049] Multi-carbon batteries, such as figure 1 As shown, it includes a first porous activated carbon layer 1, a metal oxide layer 3, and a second porous activated carbon layer 5. A first diaphragm layer 2 is provided between the first porous activated carbon layer 1 and the metal oxide layer 3. A second diaphragm layer 4 is provided between the two porous activated carbon layers 5 and the metal oxide layer 3;

[0050] The first porous activated carbon layer 1 includes the following components, which are specifically as follows:

[0051] Activated carbon 80%;

[0052] Acetylene black 15%;

[0053] Thickener 5%;

[0054] The metal oxide layer 3 includes the following components, which are specifically as follows:

[0055] Phosphorus iron lithium carbonate mixture 75%;

[0056] Carbon black 20%;

[0057] Gel adhesive 5%;

[0058] The second porous activated carbon layer 5 includes the following components, which are specifically as follows:

[0059] Activated carbon 80%;

[0060] Acetylene bl...

Embodiment 2

[0066] Same as Example 1, the difference is that the first porous activated carbon layer (1) includes the following components, specifically as follows:

[0067] Activated carbon 87%;

[0068] Acetylene black 10%;

[0069] Thickener 3%;

[0070] The metal oxide layer (3) includes the following components, specifically as follows:

[0071] Phosphorus iron lithium carbonate mixture 88%;

[0072] Carbon black 10%;

[0073] Gel adhesive 2%;

[0074] The second porous activated carbon layer (5) includes the following components, specifically as follows:

[0075] Activated carbon 87%;

[0076] Acetylene black 10%;

[0077] Thickener 3%.

[0078] The thickness of the first diaphragm layer 2 is 0.020 mm, and the thickness of the second diaphragm layer 4 is 0.020 mm.

Embodiment 3

[0080] Same as Example 1, the difference is that the first porous activated carbon layer (1) includes the following components, specifically as follows:

[0081] Activated carbon 70%;

[0082] Acetylene black 20%;

[0083] Thickener 10%;

[0084] The metal oxide layer (3) includes the following components, specifically as follows:

[0085] Phosphorus iron lithium carbonate mixture 60%;

[0086] Carbon black 30%;

[0087] Gel adhesive 10%;

[0088] The second porous activated carbon layer (5) includes the following components, specifically as follows:

[0089] Activated carbon 70%;

[0090] Acetylene black 20%;

[0091] Thickener 10%.

[0092] The thickness of the first diaphragm layer 2 is 0.025 mm, and the thickness of the second diaphragm layer 4 is 0.025 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com