Lower hydrocarbon fracturing fluid gelling agent with polyalcohol synergism and preparation method thereof

A technology of low-carbon hydrocarbons and polyols, applied in the field of high-efficiency gelling agent synthesis, can solve the problems of continuous mixing on site and slow cross-linking rate, etc., and achieve excellent results, simple preparation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

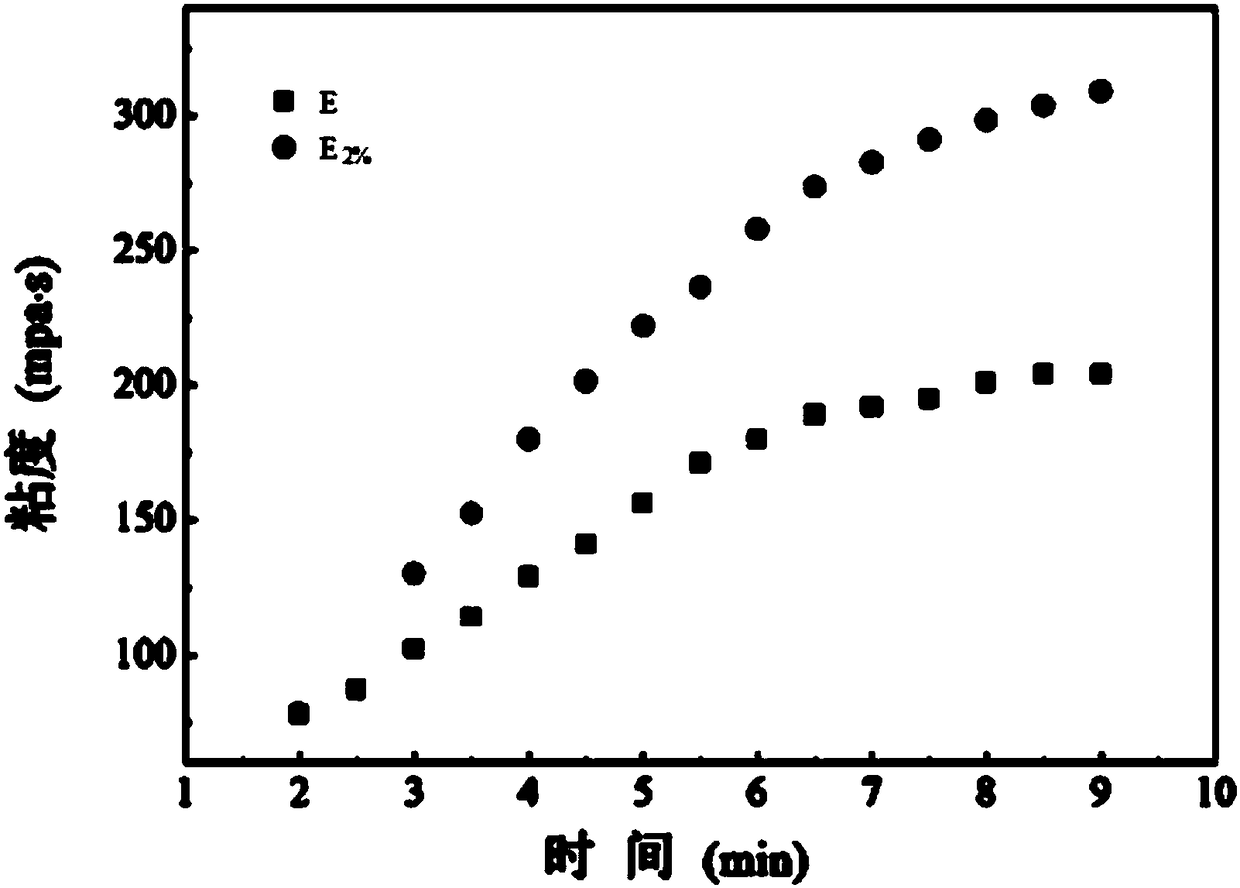

Embodiment 1

[0028] Add 48.50g of triethyl phosphate into a 250mL three-necked flask equipped with mechanical stirring and a thermometer, then add 29.20g of phosphorus pentoxide in three batches within 1 to 1.5 hours, react at 85°C for 5 hours, then cool down to room temperature. A polyphosphate intermediate is obtained. Add mixed alcohol (including 5.44g ethanol, 15.02g n-octanol, 26.63g n-hexadecyl alcohol and 0.95g dipentaerythritol) to the system, react at 95°C, add 3.76g aluminum chloride when reacting for 2 hours, and continue the reaction for 4 hours Finish the reaction, lower to room temperature to obtain polyol synergistic low-carbon hydrocarbon fracturing fluid gelling agent E 2% , with a density of 1.06g / cm 3 .

Embodiment 2

[0030] Add 48.50g of triethyl phosphate into a 250mL three-necked flask equipped with mechanical stirring and a thermometer, then add 29.20g of phosphorus pentoxide in three batches within 1 to 1.5 hours, react at 85°C for 5 hours, then cool down to room temperature. A polyphosphate intermediate is obtained. Add mixed alcohols (including 5.44g ethanol, 15.02g n-octanol, 26.63g n-hexadecyl alcohol and 1.88g dipentaerythritol) to the system, react at 95°C, add 2.82g aluminum sulfate when reacting for 2h, continue to react for 4h Finish the reaction, lower to room temperature to obtain polyol synergistic low-carbon hydrocarbon fracturing fluid gelling agent E 4% , with a density of 1.03g / cm 3 .

Embodiment 3

[0032] Add 48.50g of triethyl phosphate into a 250mL three-necked flask equipped with mechanical stirring and a thermometer, then add 29.20g of phosphorus pentoxide in three batches within 1 to 1.5 hours, react at 85°C for 5 hours, then cool down to room temperature. A polyphosphate intermediate is obtained. Add mixed alcohol (including 7.10g ethanol, 13.98g n-octanol, 26.01g n-hexadecyl alcohol and 1.17g dipentaerythritol) to the system, react at 95°C, add 0.88g aluminum sulfate when reacting for 2h, continue to react for 4h Finish the reaction, lower to room temperature to obtain polyol synergistic low-carbon hydrocarbon fracturing fluid gelling agent E 2.5% , with a density of 1.01g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com