Coupling gear spiral rotor pump

A rotor pump and gear technology, applied in the hydraulic field, can solve the problems of gear meshing oil traps, low volumetric efficiency, lack of interchangeability, etc., and achieve the effects of improving overall efficiency, high volumetric efficiency, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

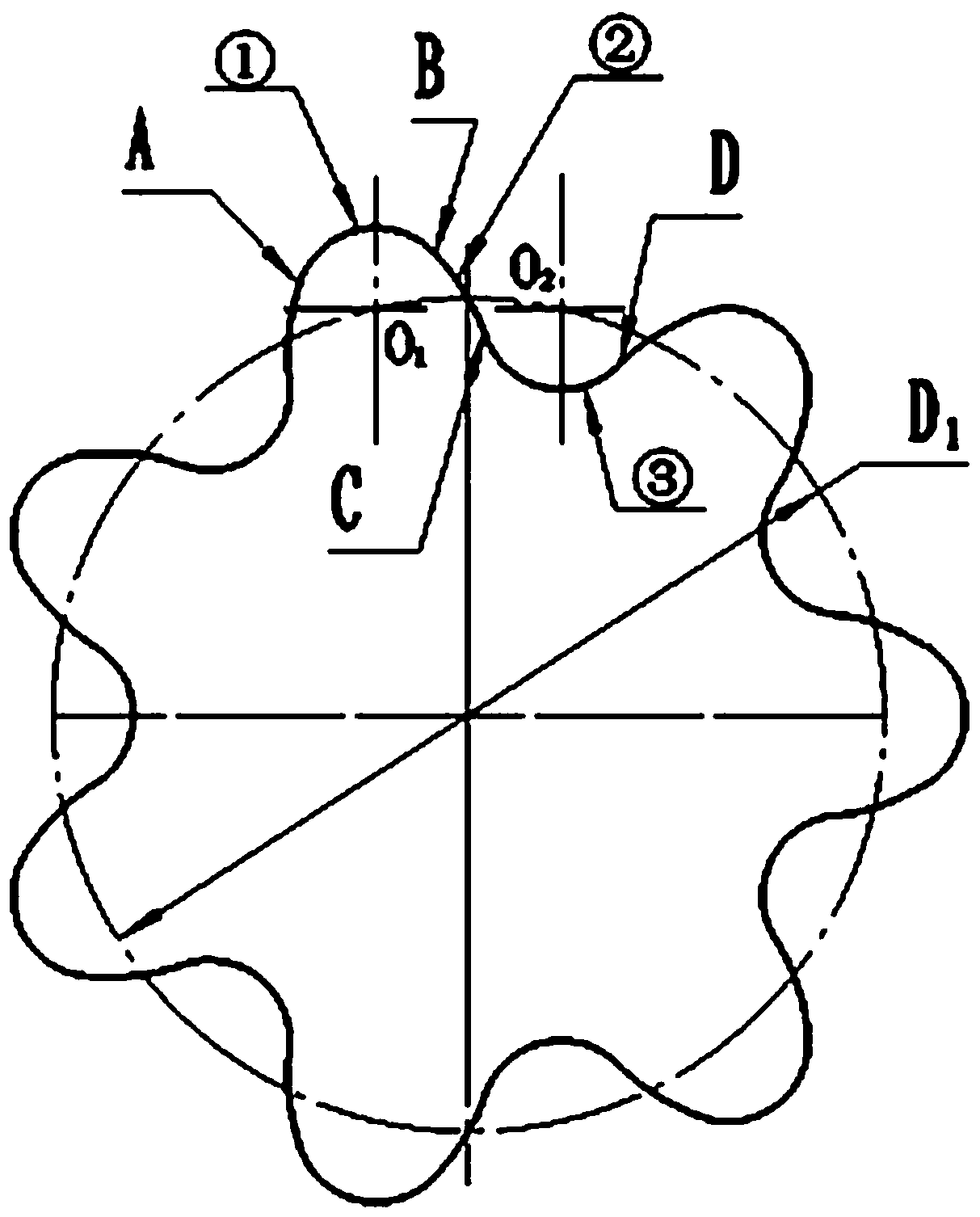

[0037] Technical features and effects of the present invention: 1. The rotor of the pump adopts multi-section coupling curves for tooth profile, and the rotor adopts helical tooth profile design;

[0038] 2. On the end cover where the axial force is directed, the axial force automatic compensation structure design is used to overcome the adverse effects of the axial force;

[0039] 3. The use of DU sliding bearings enables the rotor to move axially, achieving automatic axial clearance compensation and reducing leakage;

[0040] 4. In the radial direction, the mutual self-compression of different materials realizes the balance of forces and achieves the best clearance;

[0041] 5. A transition joint is added at the end of the driving shaft, and the switch between the flat key and the spline can be realized only by improving the transition joint.

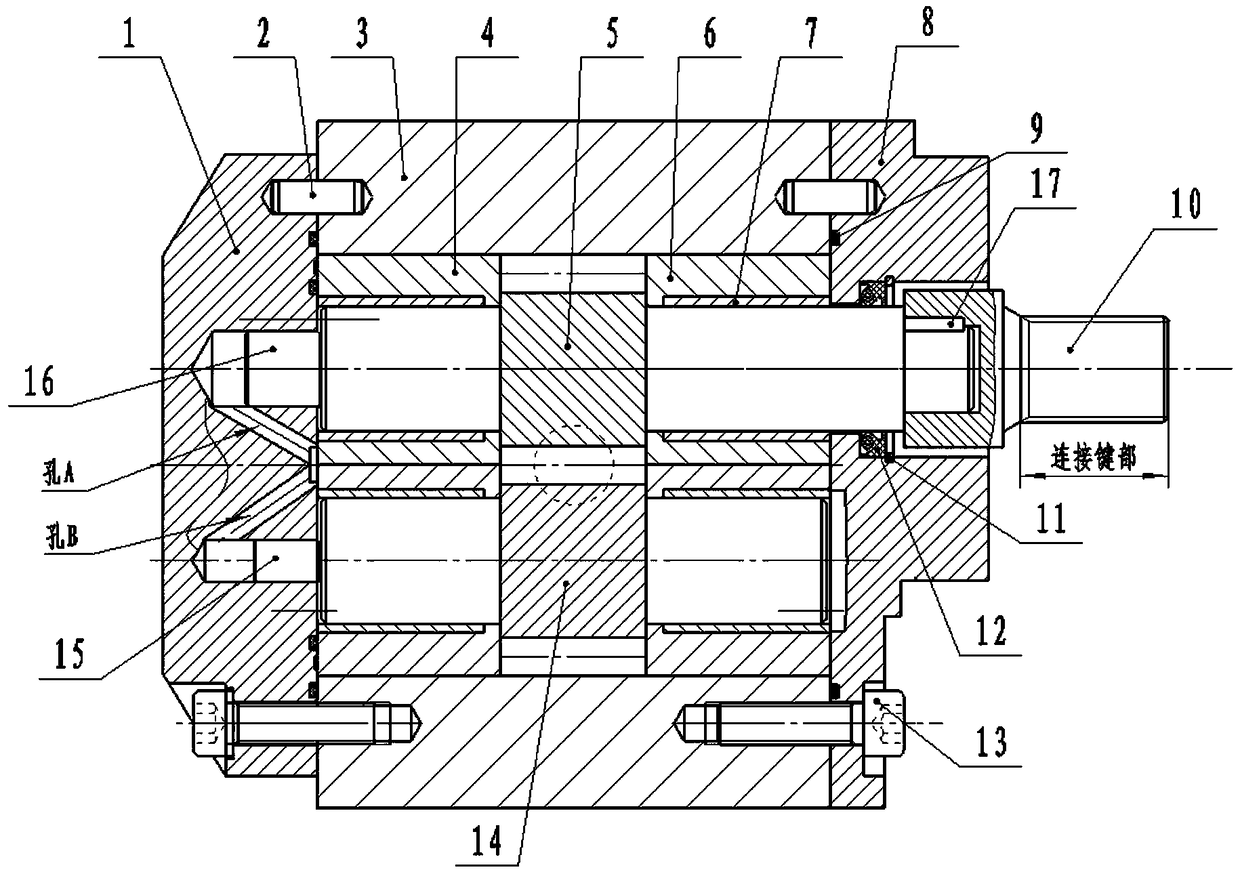

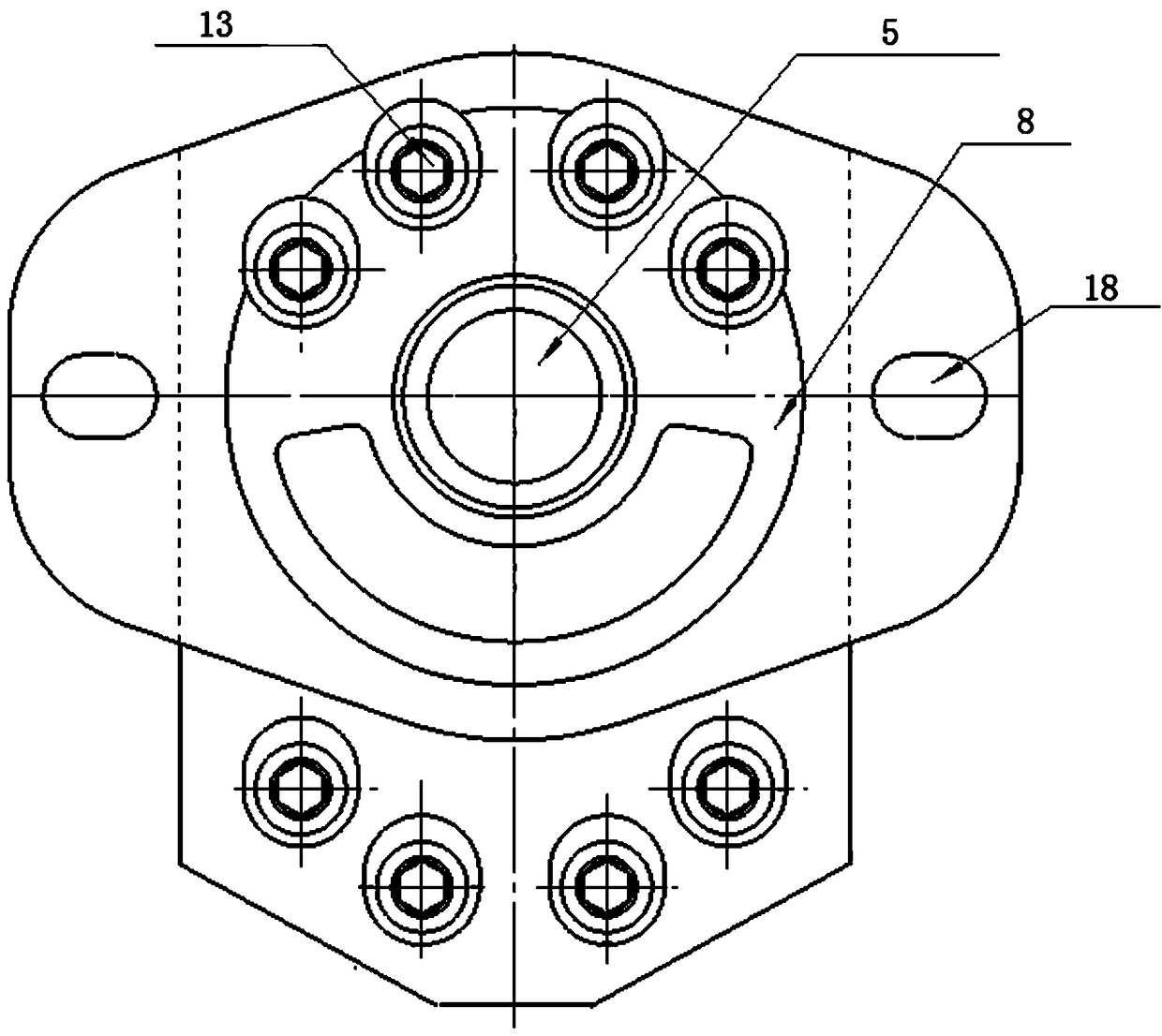

[0042] figure 1 Shown is the overall structure diagram, the main components are: bottom cover 1, positioning pin shaft 2, pump bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com