Humidifying device and corrugating machine

A humidification device and heating mechanism technology, applied in the field of corrugating machines, can solve problems such as the decline in the production efficiency of corrugated paper, and achieve the effects of suppressing heat dissipation, easily maintaining proper temperature, and easily managing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0053] In addition, each embodiment shown below is just an illustration, and it does not intend to exclude the application of various deformation|transformation and techniques not expressly shown in the following embodiment. Each configuration of the following embodiments can be implemented in various modifications without departing from the gist thereof, and can be selected or combined as necessary.

[0054] [1. Double-sided machine and its surrounding structure]

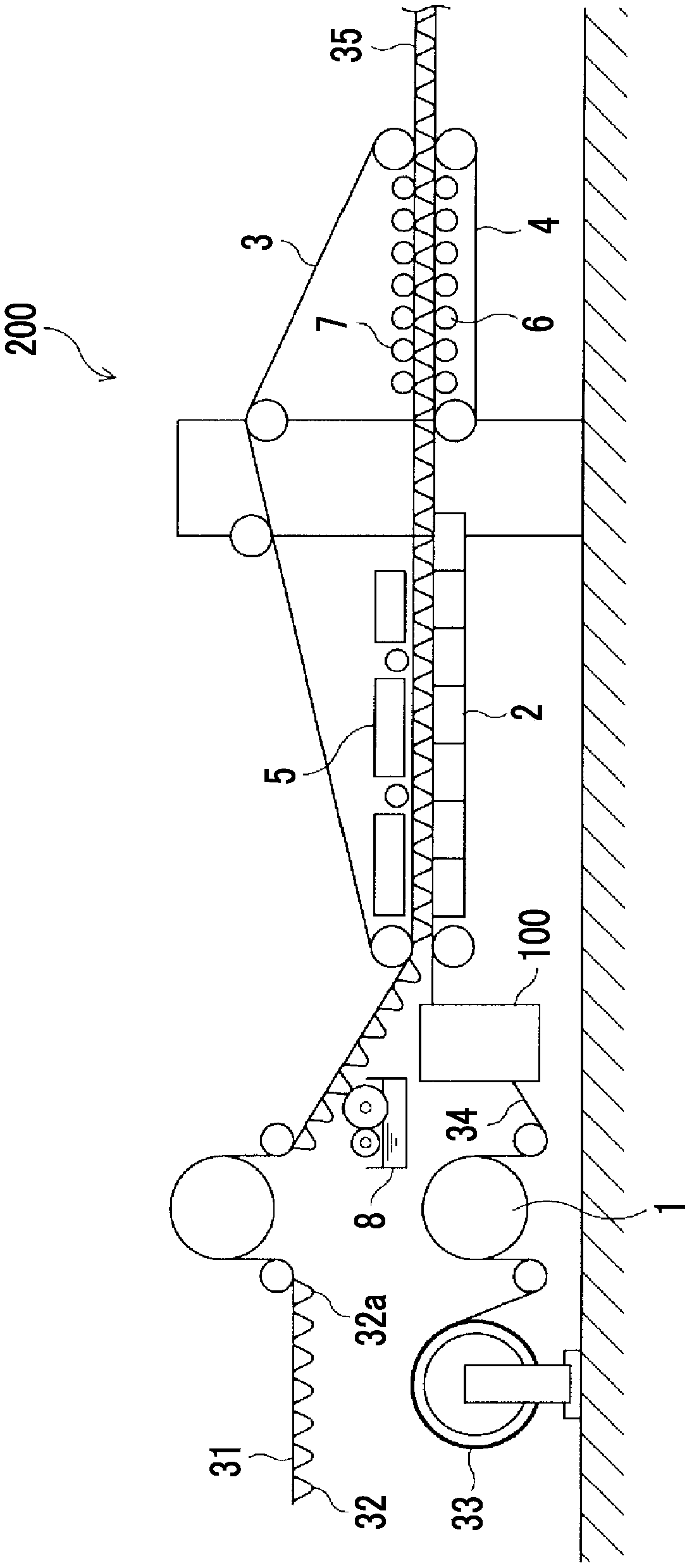

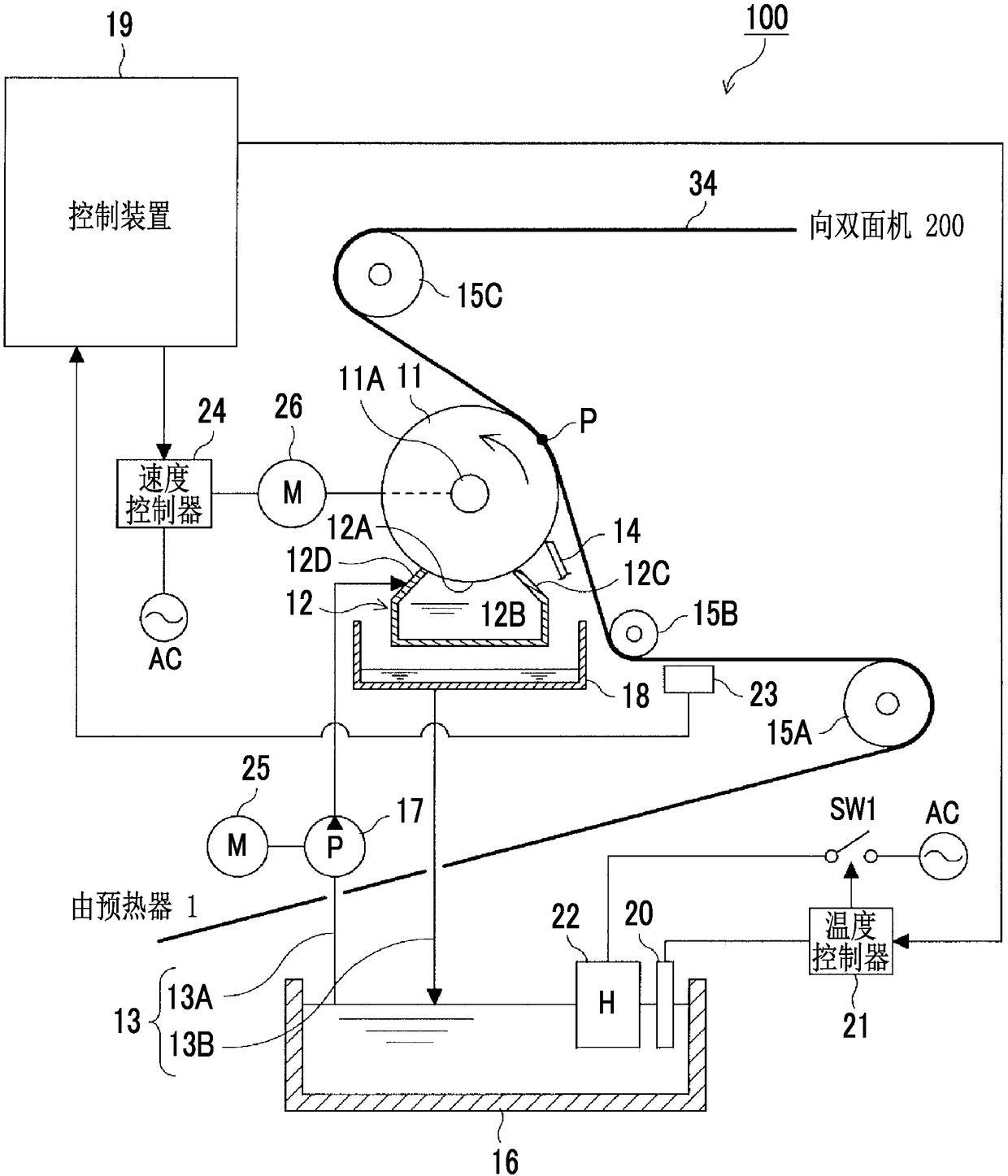

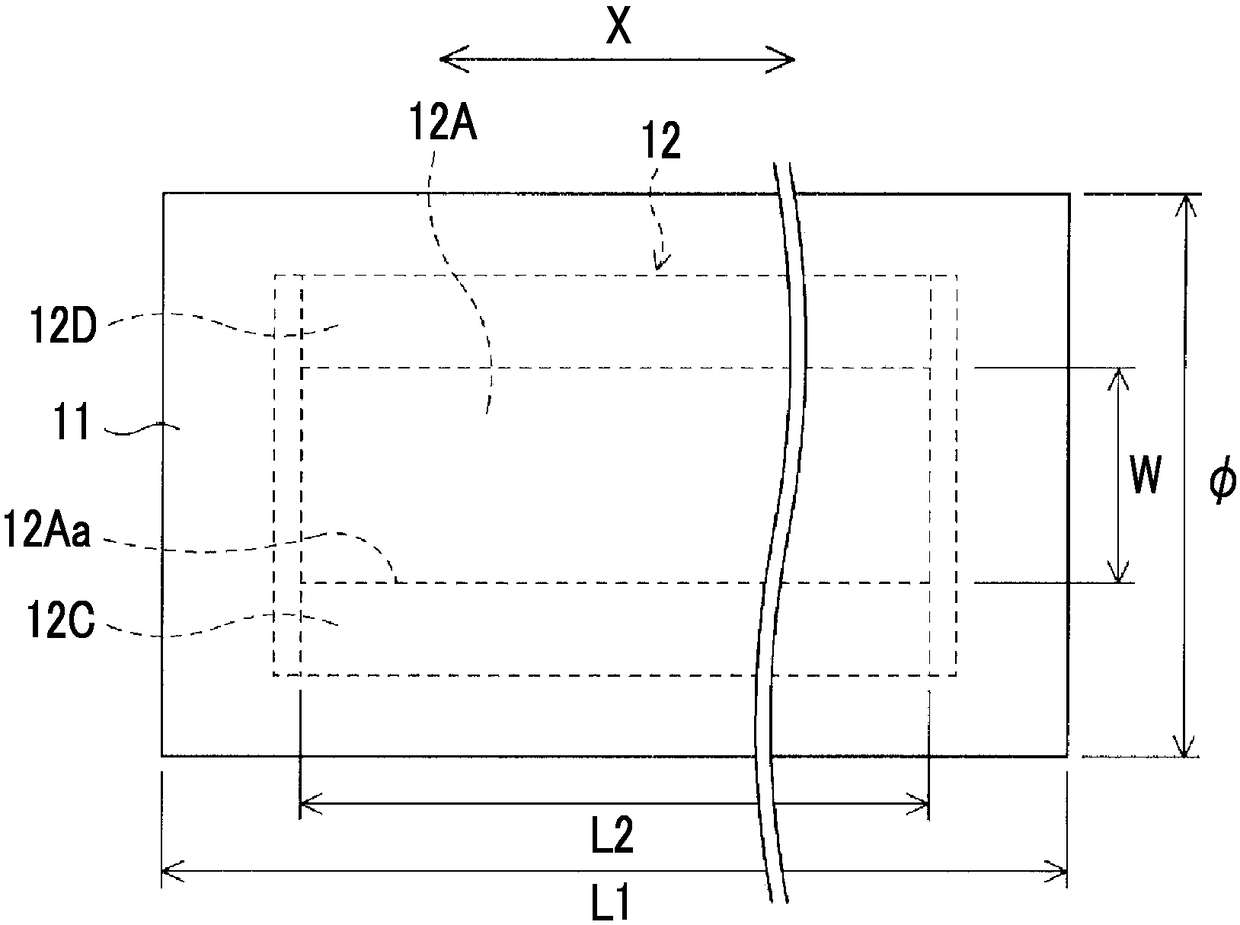

[0055] figure 1 It is a schematic side view extracting and showing the double-facer of the corrugating machine concerning this embodiment, and its vicinity. Such as figure 1 As shown, the double-facer 200 laminates the face paper 34 on the single-face corrugated paper 31 manufactured by the single-facer (not shown) to manufacture the double-face corrugated paper 35 . Therefore, in one direction ( figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com