Packaging material and packaging container

A technology for packaging containers and packaging materials, applied in the field of packaging materials and packaging containers, can solve the problems of foam deterioration, polymer foam collapse, high cost-effectiveness, etc., and achieve the effect of improving rigidity, adhesion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

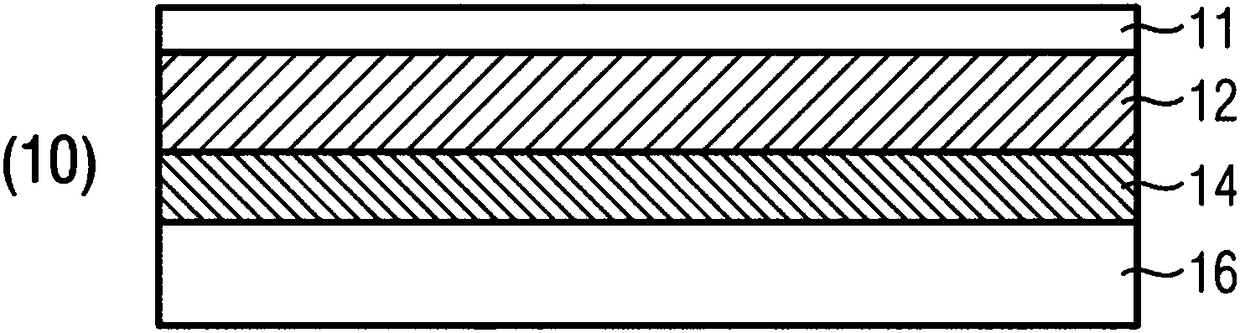

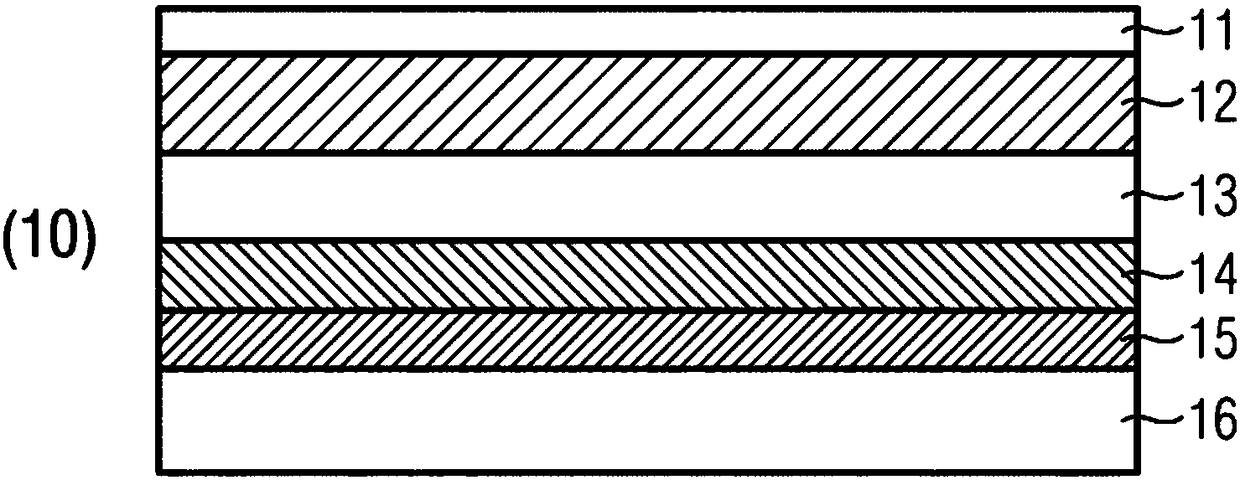

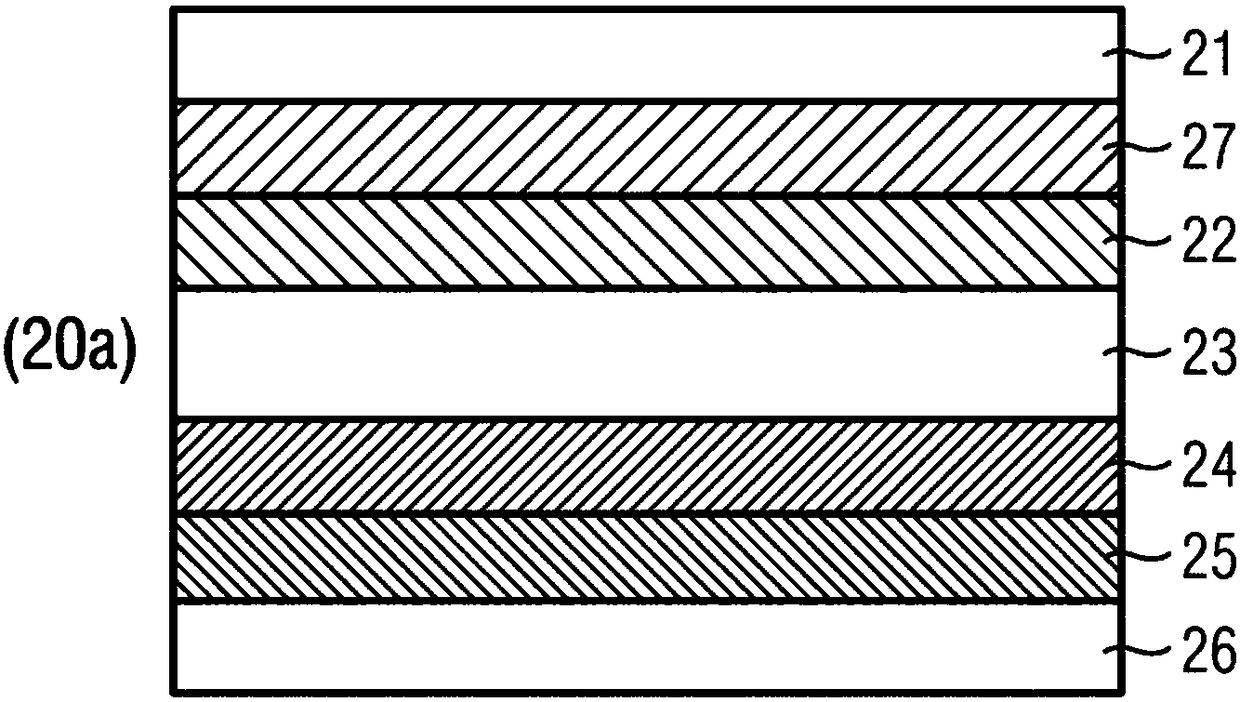

[0136] A packaging material for packaging containers of liquid or semi-liquid food, comprising a decorative layer (11), the packaging material has a main body layer (12) on one side of the decorative layer, the main body layer (12) has a thickness less than 700kg / m 3 Cross-linked foamed cellulose having a density and thickness of at least 25% of the main body layer having a barrier layer (14) on the side opposite to the decorative layer (11), said barrier layer being opposite to the main body layer ( 12) The opposite side has a heat sealable layer (16).

[0137] The packaging material includes an adhesive between the heat-sealable layer and the barrier layer.

[0138] The packaging material includes a laminate layer between the chassis layer and the barrier layer.

[0139] The packaging material includes an additional layer between the decorative layer and the main body layer.

[0140] Said packaging material, wherein said additional layer is a paper or paperboard layer or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com