Method for recycling waste masks

A technology for recycling and processing masks, applied in the field of fiber material recycling, can solve problems such as low tensile strength, low elongation, cracking, etc., and achieve the effects of improving bonding performance, improving bending resistance, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

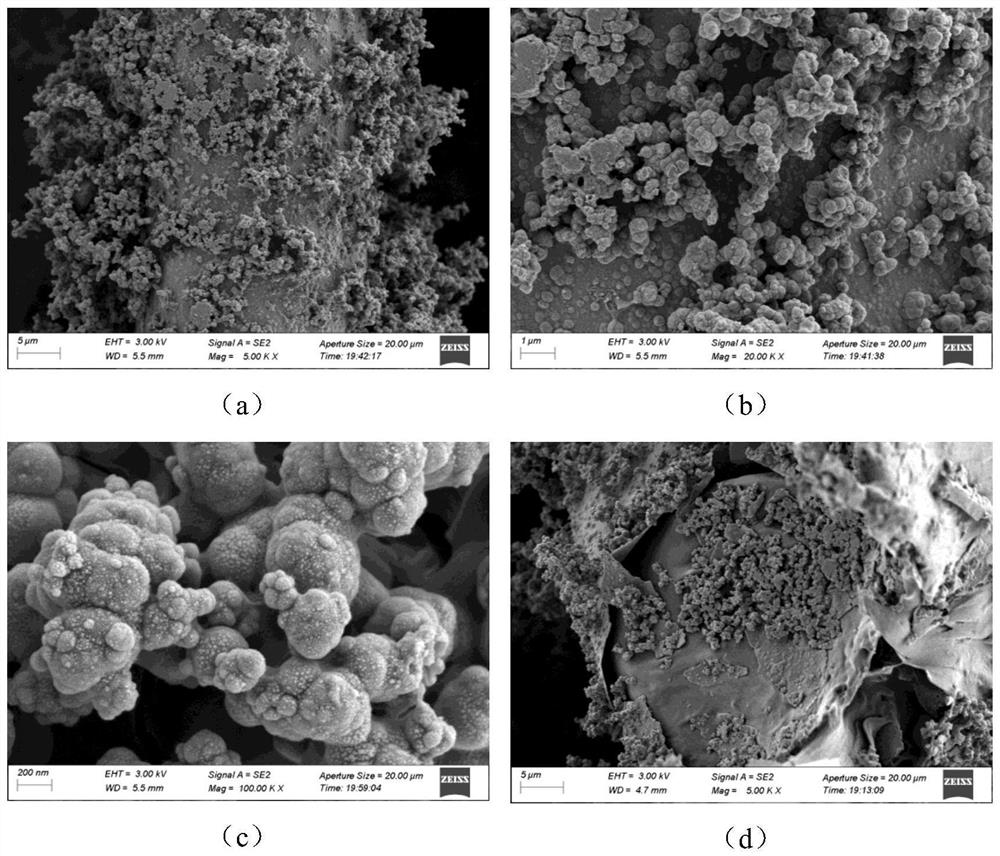

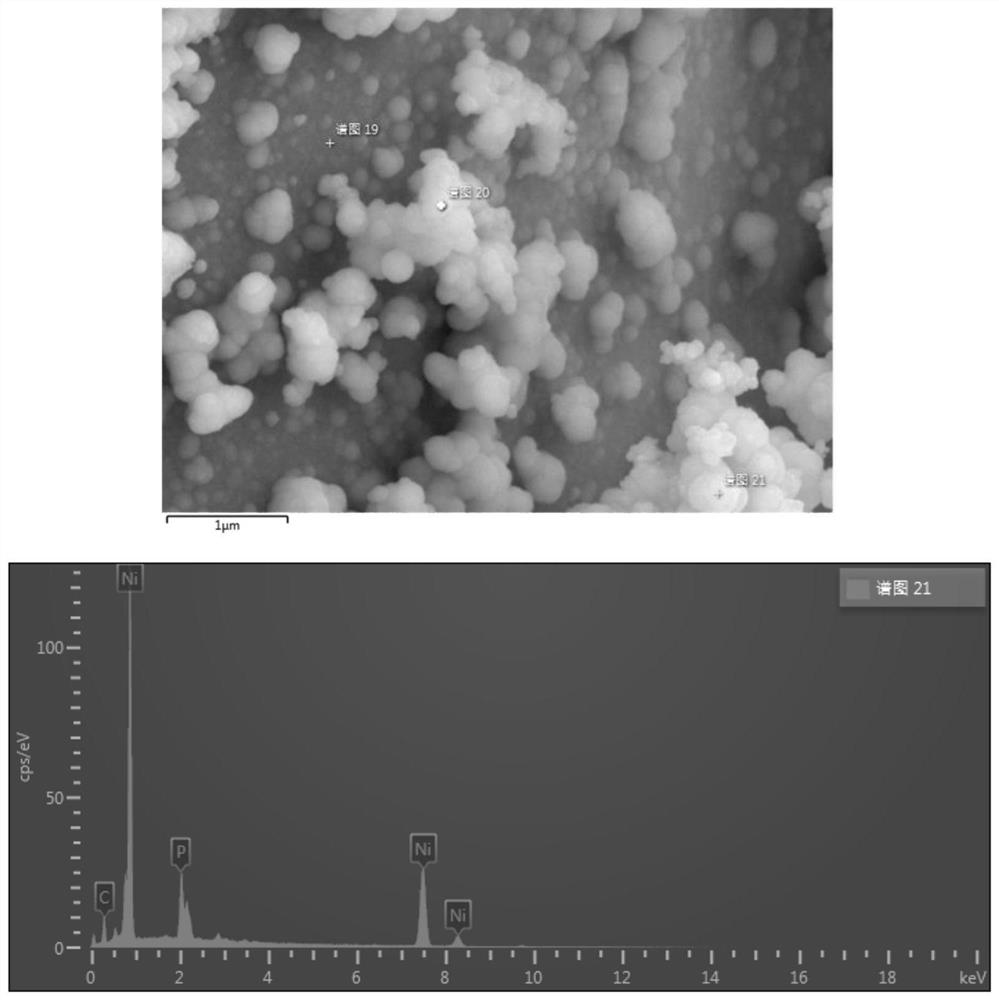

[0031] Subtract the nose bridge strip and the surrounding joints of the discarded masks, and cut the remaining part into mask fibers with a length of 15mm and a width of 2mm. Then put the mask fiber into the roughening solution, the sensitization solution, and the palladium chloride solution with a pH of 2 for ultrasonic treatment for 10 minutes, ultrasonic power 240W, and ultrasonic temperature 30°C. The composition of the roughening solution is 90 parts of concentrated sulfuric acid, 100 parts of ammonium persulfate and 1000 parts of water; the composition of the sensitization solution is 20 parts of stannous chloride, 15 parts of hydrochloric acid and 980 parts of water; the palladium chloride solution is 0.3 parts of palladium chloride , 100 parts of water.

[0032] After the treatment, the mask fibers were put into the plating bath for treatment. The plating solution was placed in a constant temperature water bath at a temperature of 60°C. After 10 minutes of treatment, t...

Embodiment 2

[0037] Subtract the nose bridge strip and the surrounding joints of the discarded masks, and cut the remaining part into mask fibers with a length of 15mm and a width of 2mm. Then put the mask fiber into the roughening solution, the sensitization solution, and the palladium chloride solution with a pH of 2 for ultrasonic treatment for 5 minutes, ultrasonic power 200W, and ultrasonic temperature 30°C. The composition of the roughening solution is 90 parts of concentrated sulfuric acid, 100 parts of ammonium persulfate and 1000 parts of water; the composition of the sensitization solution is 20 parts of stannous chloride, 15 parts of hydrochloric acid and 980 parts of water; the palladium chloride solution is 0.5 parts of palladium chloride , 100 parts of water.

[0038] After the treatment, the mask fibers were put into the plating bath for treatment. The plating solution was placed in a constant temperature water bath at a temperature of 60°C. After 10 minutes of treatment, th...

Embodiment 3

[0043] The preparation method of this embodiment is the same as that of Example 1, except that the pH of the palladium chloride solution is 4, and the mask fiber mortar Y2 is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com