Weak vortex thick oil defoaming separator

A separator and heavy oil technology, which is applied in the direction of foam dispersion/prevention, can solve the problems affecting the safety of crude oil collection and transportation pipelines and equipment, incomplete oil and gas separation, and large errors in metering instruments, achieving compact structure, complete oil and gas separation, Use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the specification.

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

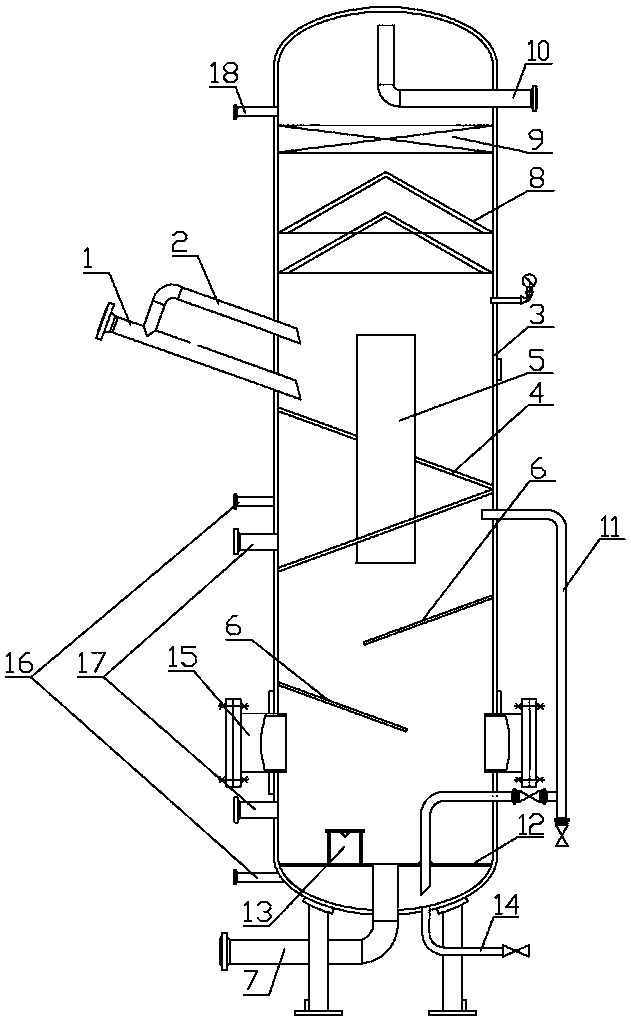

[0020] as attached figure 1 As shown, the weak swirl heavy oil defoaming separator includes a cylinder body 3 and a liquid inlet device; the liquid inlet device includes a liquid phase pipe 1 and a gas phase pipe 2, and the upper side of the liquid phase pipe 1 is connected with a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com