Molecular sieve, sound absorbing material comprising same as well as loudspeaker

A technology of sound-absorbing materials and molecular sieves, applied in the direction of molecular sieves and alkali exchange compounds, molecular sieve compounds, molecular sieve characteristic silicates, etc., can solve the problems of reducing the effect of bass improvement, single surface properties, and difficulty in entering and exiting air molecules to achieve performance stability Boost, Boost Bass Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

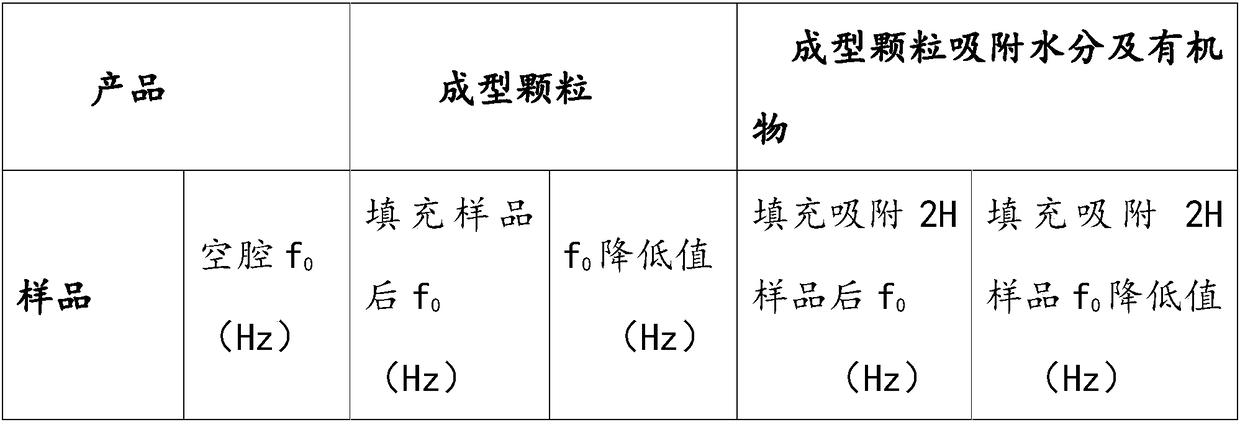

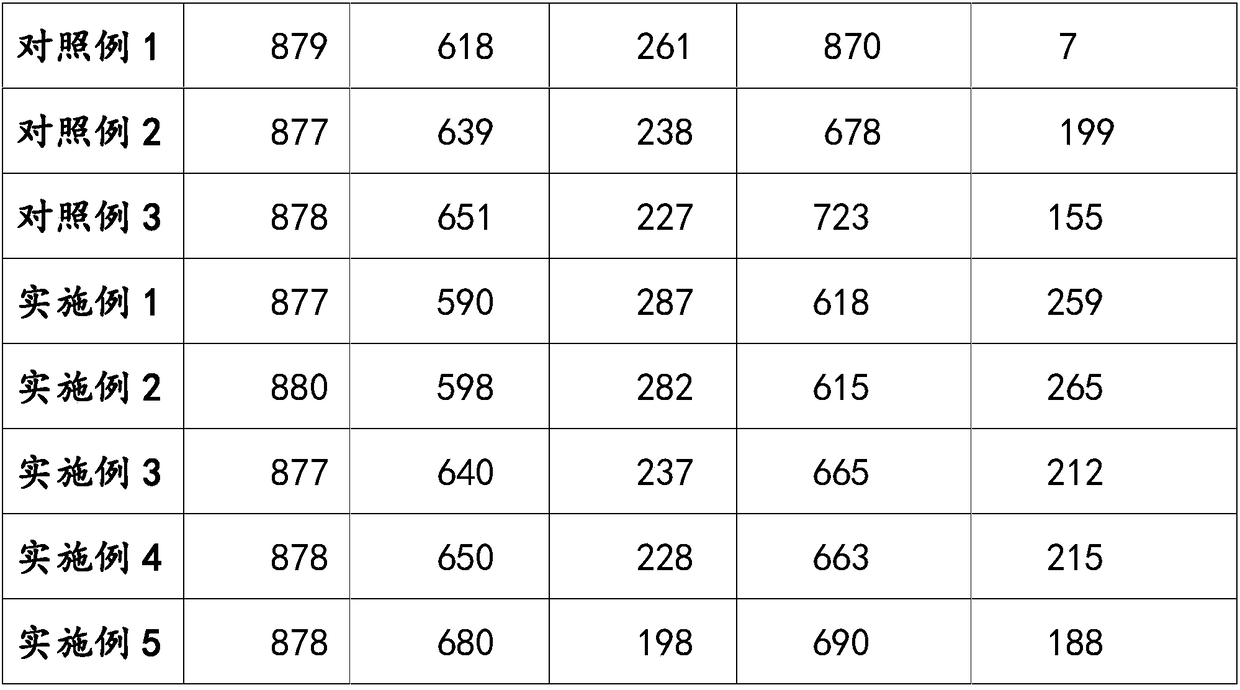

Embodiment 1

[0026] ZSM-5 (silicon-aluminum ratio 500, MFI structure) is a core-shell molecular sieve with MCM-41 as the shell. The diameter of the core layer is 1-5um, and the thickness of the shell layer is 0.2-0.5um. In the 1mL cavity of the body, test f 0 ; Simultaneously, in order to test the sound-absorbing effect of the core-shell molecular sieve after adsorbing organic substances, some particles are placed in a closed space with toluene / butyl acrylate (volume ratio 1:1), and its relative humidity is 70%-80%, 2 After one hour, take it out and put it into a 1mL cavity with a speaker unit to test f 0 .

Embodiment 2

[0028] ZSM-5 (silicon-aluminum ratio 500, MFI structure) is the core, and the mesoporous silica of the two-dimensional hexagonal P6MM structure is the core-shell molecular sieve. The diameter of the core layer is 0.7-8um, and the thickness of the shell layer is 0.05-0.2um. Pellet molding, filled with a speaker monomer 1mL cavity, test f 0 ; In order to test the sound-absorbing effect of the core-shell molecular sieve after adsorbing organic substances, some particles were placed in a closed space with toluene / butyl acrylate (volume ratio 1:1) at a relative humidity of 70%-80% for 2 hours Finally, take it out and put it into a 1mL cavity with a speaker unit to test f 0 .

Embodiment 3

[0030] Silicalite-1 (MFI structure) is the core, and ZSM-5 is the core-shell molecular sieve of the shell. The diameter of the core layer is 3-8um, and the thickness of the shell layer is 0.03-0.10um. After granulation, it is filled with a 1mL cavity with a speaker unit , test f 0 ; In order to test the sound-absorbing effect of the core-shell molecular sieve after adsorbing organic substances, some particles were placed in a closed space with toluene / butyl acrylate (volume ratio 1:1) at a relative humidity of 70%-80% for 2 hours Finally, take it out and put it into a 1mL cavity with a speaker unit to test the f 0 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com