Polyolefin thermoplastic elastomer and processing method thereof

A thermoplastic elastomer and polyolefin technology is applied in the field of elastomers to achieve the effects of easy processing, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

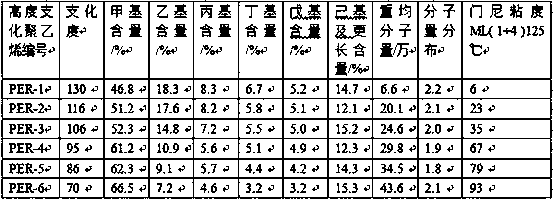

[0022] A polyolefin thermoplastic elastomer, according to 100 parts by weight, its raw materials include: 10 parts of high-density polyethylene, 90 parts of highly branched polyethylene, 0.1 part of antioxidant 1010, wherein the density of high-density polyethylene is 0.976 g / cm 3 , The degree of crystallinity is 90%, and the softening point is 135°C; among them, the number of highly branched polyethylene used is PER-4.

[0023] A processing method of a polyolefin thermoplastic elastomer, specifically comprising the following steps:

[0024] (1) Mix high-density polyethylene, highly branched polyethylene, and antioxidant 1010 in a mixer,

[0025] (2) Polyolefin thermoplastic elastomer was prepared by melt blending at 190°C.

Embodiment 2

[0027] According to 100 parts by weight of the polyolefin thermoplastic elastomer, its raw materials include: 50 parts of high-density polyethylene, 50 parts of highly branched polyethylene, and 1 part of antioxidant 168.

[0028] Among them, the density of high-density polyethylene is 0.940 g / cm 3 , The degree of crystallinity is 80%, and the softening point is 125°C; among them, the number of highly branched polyethylene used is PER-3.

[0029] The processing method of the polyolefin thermoplastic elastomer specifically comprises the following steps:

[0030] (1) Mix high-density polyethylene, highly branched polyethylene, and antioxidant 168 in a mixer;

[0031] (2) Polyolefin thermoplastic elastomer was prepared by melt blending at 230°C.

Embodiment 3

[0033] Polyolefin thermoplastic elastomer, based on 100 parts by weight, its raw materials include: 40 parts of high-density polyethylene, 60 parts of highly branched polyethylene, 0.5 part of antioxidant 1076, and the density of high-density polyethylene is 0.958 g / cm 3 , The degree of crystallinity is 85%, and the softening point is 131°C; among them, the highly branched polyethylene used is 20 parts of PER-1 and 40 parts of PER-6.

[0034] The processing method of polyolefin thermoplastic elastomer specifically comprises the following steps:

[0035] (1) Mix high-density polyethylene, highly branched polyethylene, and antioxidant 1076 in a mixer;

[0036] (2) Polyolefin thermoplastic elastomer was prepared by melt blending at 210°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com