Variable-flow type water pump

A flow and variable technology, applied in non-variable pumps, coolant flow control, pumps, etc., can solve the problems of large flow loss of cooling medium, large installation space, low energy utilization rate, etc., and achieve flow loss reduction Small size, energy-enhancing, and work-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

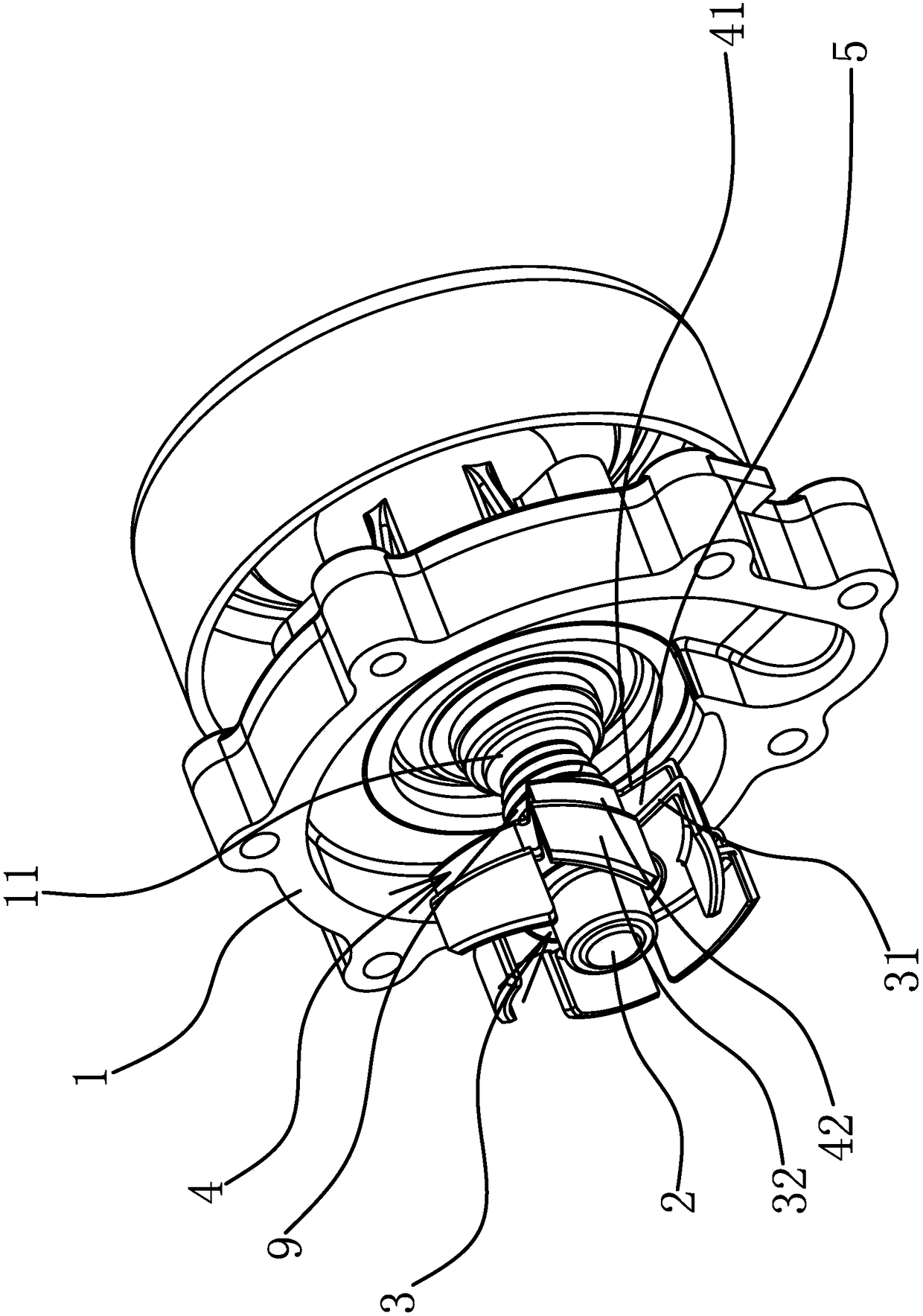

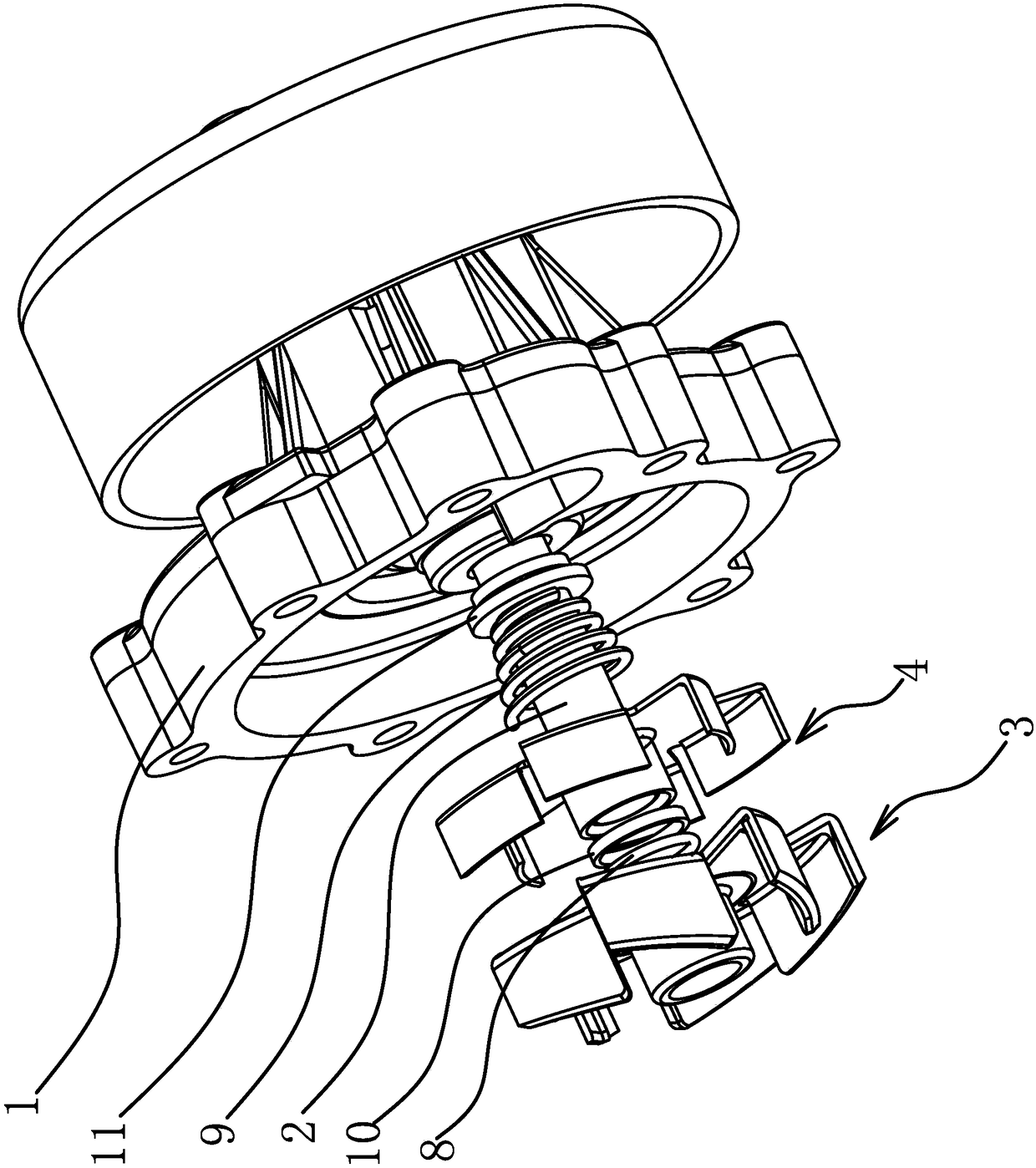

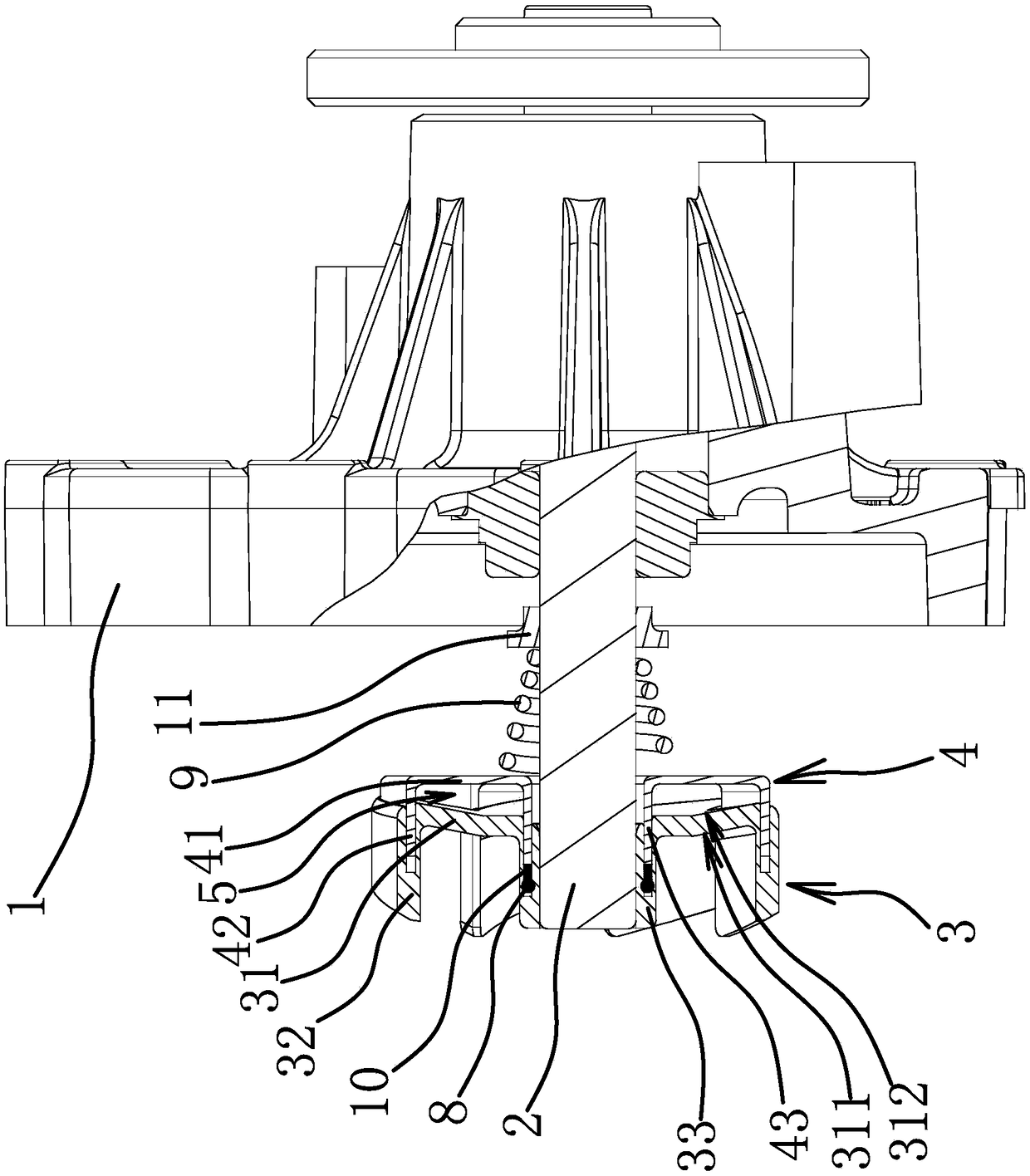

[0027] Specifically, as figure 1 and figure 2 As shown, the variable flow water pump includes a pump casing 1, a pump shaft 2, a main impeller 3 fixedly connected to the pump shaft 2, and an auxiliary shaft sleeved on the pump shaft 2 and arranged coaxially with the main impeller 3 and slidingly connected. The impeller 4, the main impeller 3 and the auxiliary impeller 4 are all open water pump impellers. The main impeller 3 has a main disk 31 and main blades 32 , and the auxiliary impeller 4 has an auxiliary disk 41 and auxiliary blades 42 . Among them, the auxiliary blade 42 corresponds to the main blade 32 one by one and is inserted into the main blade 32 so that a water collection chamber 5 is formed between the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com