Groove type solar torque box structure connected in full-hinge manner

A torque box and hinge technology, applied in the field of trough solar torque box structure, can solve the problems of low production efficiency, inconvenient installation, unsightly appearance, etc., and achieve the effects of high production efficiency, high processing accuracy and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

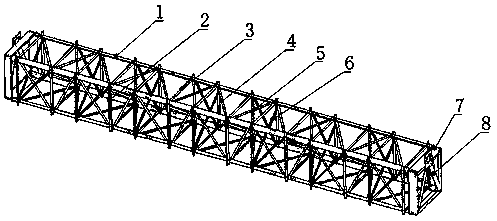

[0019] Such as figure 1 As shown, the trough solar torque box structure includes the main beam of the torque box 1, the vertical brace of the torque box 2, the horizontal brace of the torque box 3, the long diagonal brace of the torque box 4, the short diagonal brace of the torque box 5, the inner brace of the torque box 6, End connection plate 7, large font end plate 8.

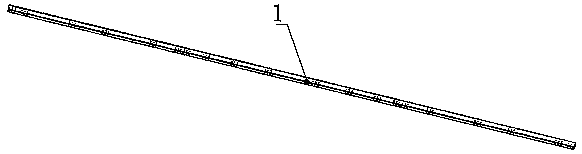

[0020] Such as figure 2 As shown, the torque box main beam 1 is an equilateral angle steel formed by cold-bending and punching a galvanized steel strip.

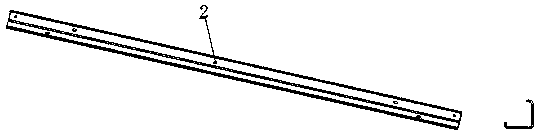

[0021] Such as image 3 As shown, the torque box stand 2 is an equilateral angle steel with bent edges formed by cold-bending and punching a galvanized steel strip.

[0022] Such as Figure 4 As shown, the torque box cross brace 3 is a U-shaped steel with bent edges formed by cold-bending and punching a galvanize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com