Digital holography and differential interference combined dual-channel phase-shift phase measuring microscope

A digital holography and differential interference technology, applied in the field of microscopes, can solve problems such as unfavorable measurement results, low utilization rate of energy and information, difficulty in adjusting shear amount and shear direction, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

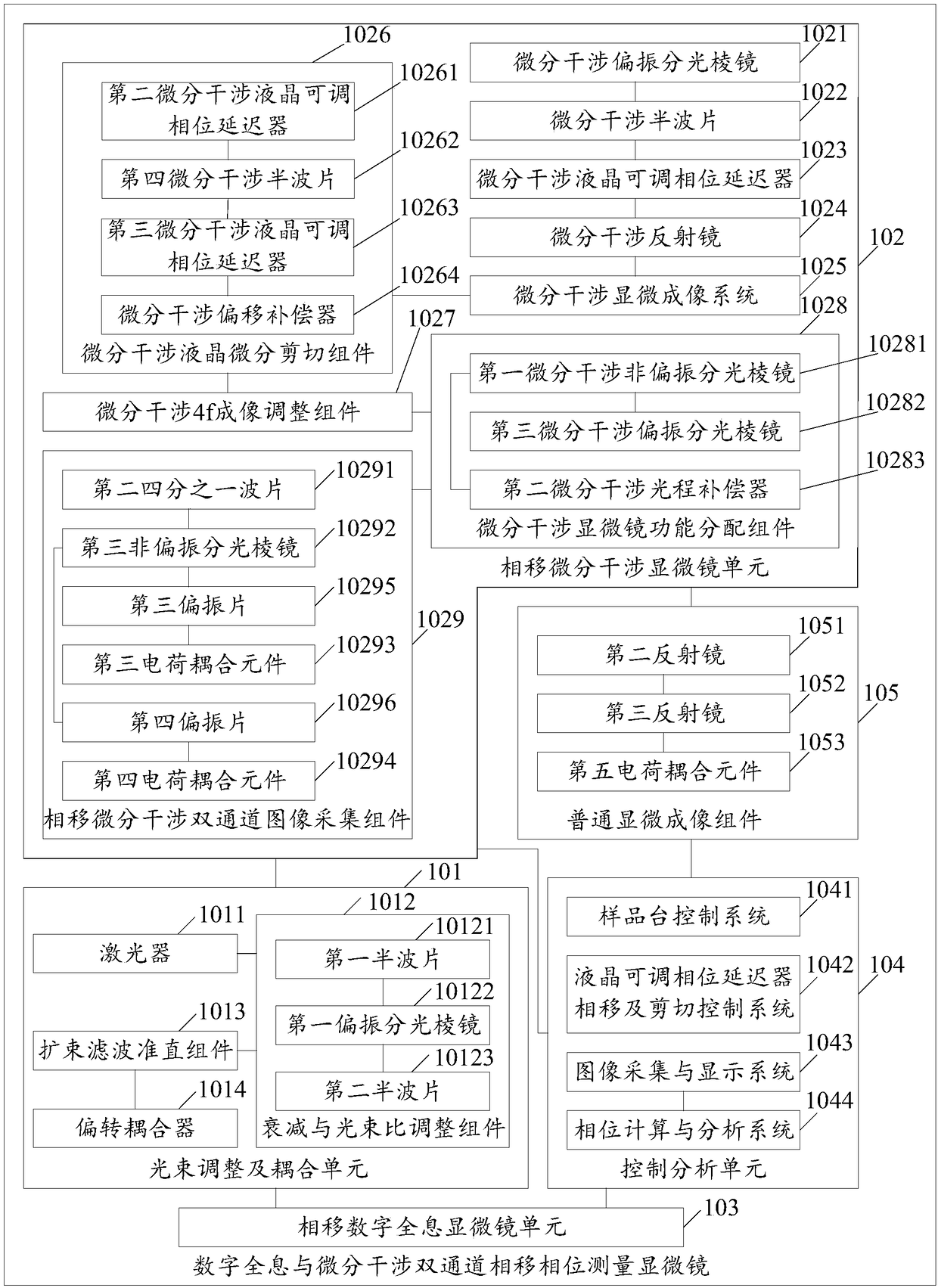

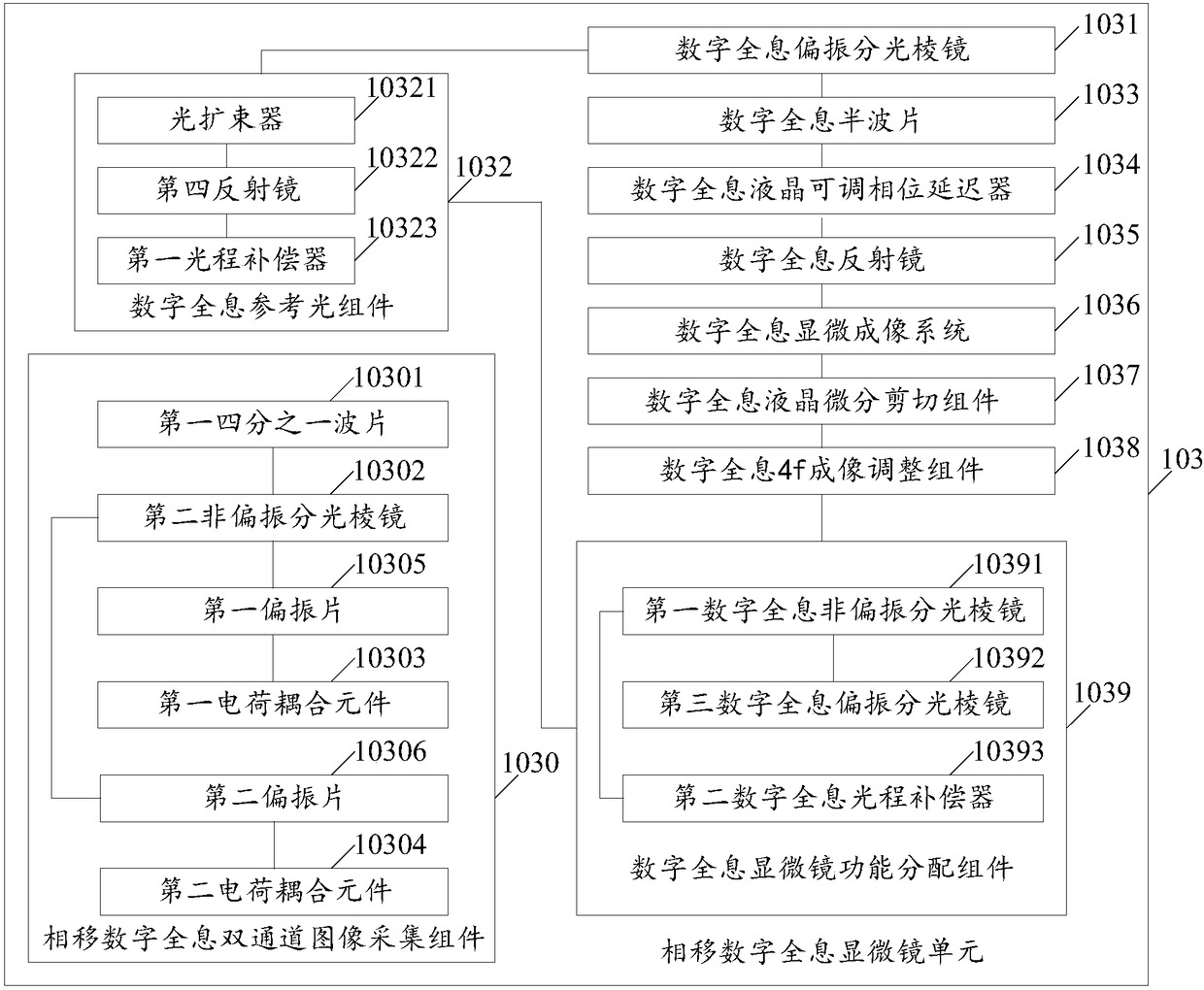

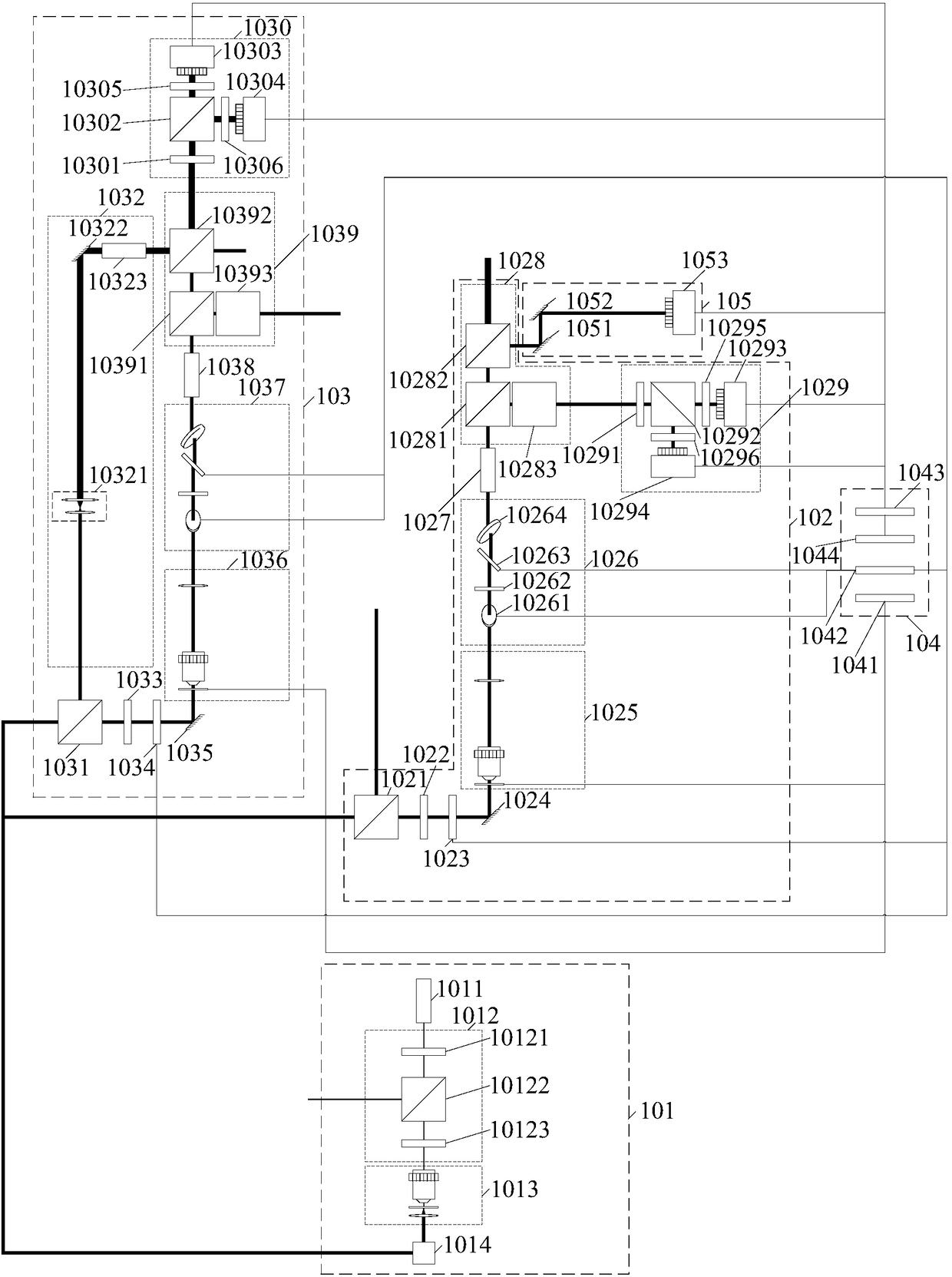

[0031] see figure 1 , figure 1 It is a schematic structural diagram of a dual-channel phase-shift phase measurement microscope that combines digital holography and differential interference disclosed in the embodiment of the present invention. Please refer to it together. figure 2 , figure 2 yes figure 1 103 out of the local refinement map. Such as figure 1 and figure 2 As shown, the dual-channel phase-shift phase measurement microscope combined with digital holography and differential interference can include a beam adjustment and coupling unit 101, a phase-shift differential interference microscope unit 102, a phase-shift digital holographic microscope unit 103, a control analysis unit 104, and a common display unit. Micro imaging assembly 105, wherein:

[0032] The beam adjustment and coupling unit 101 is used to convert the linearly polarized light output by the laser included in the beam adjustment and coupling unit 101 into orthogonally polarized light after bea...

Embodiment 2

[0098] see Figure 4 , Figure 4 It is a structural schematic diagram of another dual-channel phase-shift phase measurement microscope combined with digital holography and differential interference disclosed in the embodiment of the present invention. in, Figure 4 The shown dual-channel phase-shift phase measurement microscope combined with digital holography and differential interference is made of figure 1 and figure 2 The shown digital holography combined with differential interferometry is obtained by optimizing the dual-channel phase-shifting phase measurement microscope. and figure 1 and figure 2 The shown digital holography is compared with a two-channel phase-shifting phase measurement microscope combined with differential interference, Figure 4 In the shown dual-channel phase-shift phase measurement microscope combining digital holography and differential interference, components and devices with the same function or the same structure in the phase-shift dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com