OLED display panel and OLED display device

A display panel and encapsulation layer technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid device, etc., can solve the problems of insufficient brightness of transparent display, small aperture ratio of display panel, etc., and achieve the goal of increasing brightness and aperture ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

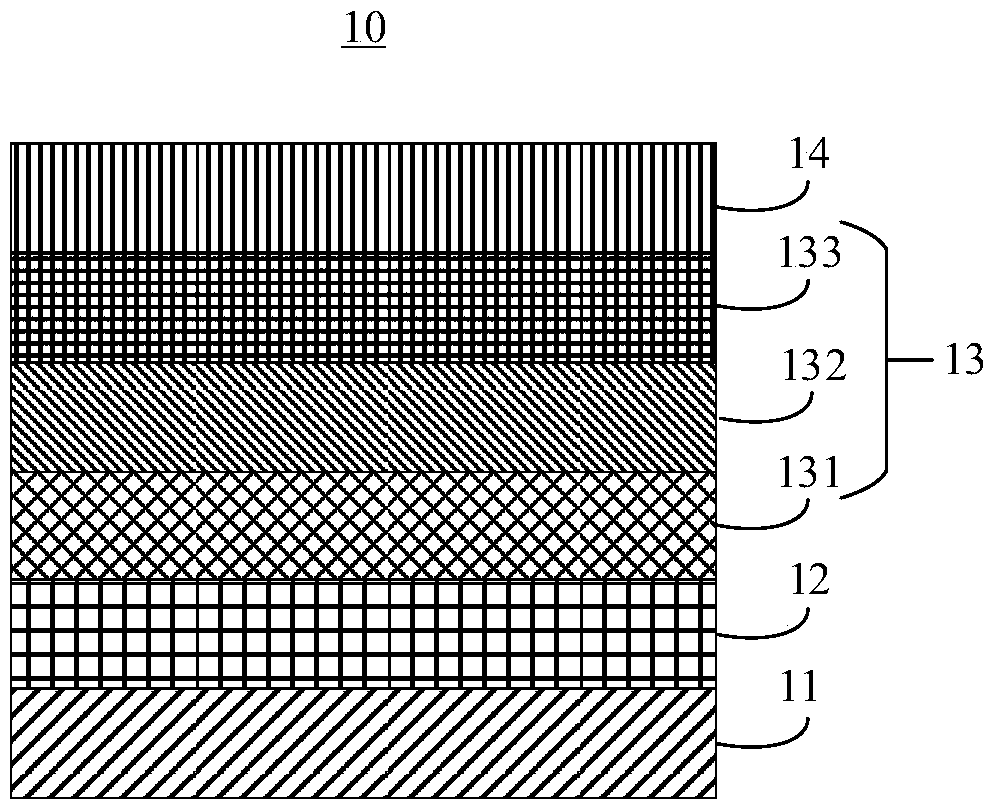

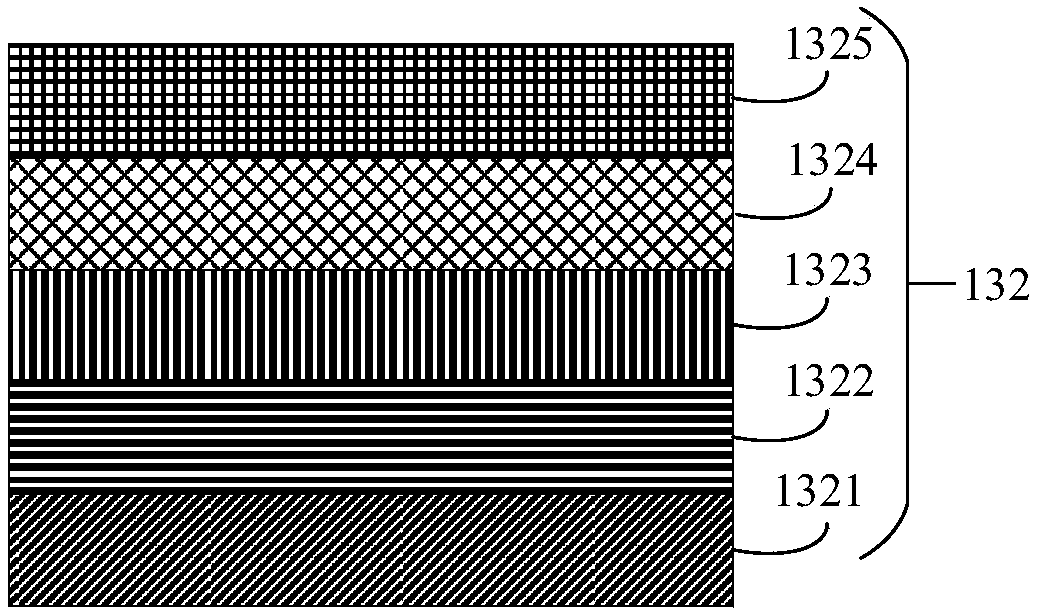

no. 1 approach

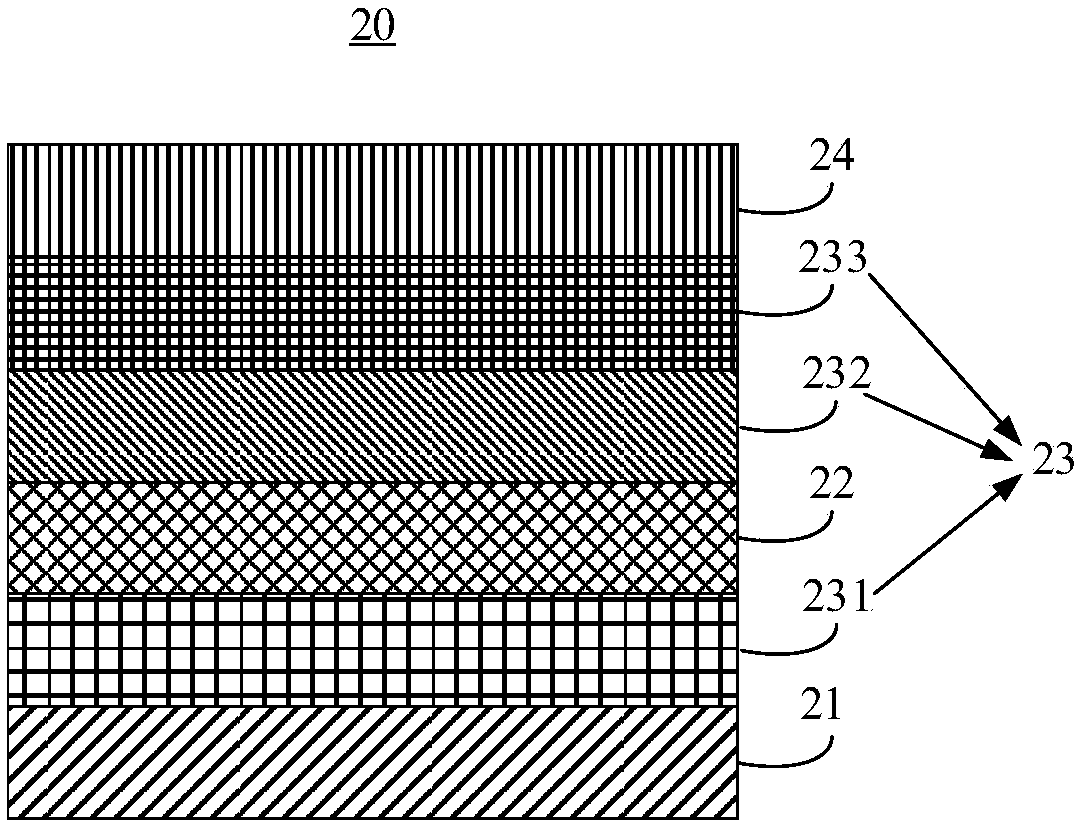

[0047] Different from the first embodiment, the location of the antireflection layer 22 in this embodiment is different. In this embodiment, the antireflection layer 22 is arranged between the anode layer 231 and the hole injection layer 2321, wherein the antireflection layer 22 The refractive index of the hole injection layer 2321 is lower than that of the hole injection layer 2321. In one embodiment, the refractive index of the hole injection layer 2321 ranges from 1.5 to 1.8, and the refractive index of the antireflection layer 22 ranges from 1.2 to 1.4.

[0048] The manufacturing process of the OLED display panel 20 of this embodiment is basically the same as that of the first embodiment, but it is different from the first embodiment. After 231 is prepared, the antireflection layer 22 is fabricated, and then the hole injection layer 2321, the hole transport layer 2322, the light emitting layer 2323, the electron transport layer 2324, the electron injection layer 2325, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com