Fire extinguisher management system

A management system and fire extinguisher technology, applied in the field of fire extinguisher management system, can solve the problems of inaccurate and comprehensive detection results, cumbersome design and installation, waste of manpower and material resources, etc., to improve management efficiency and quality, and stable signal transmission , the effect of low false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

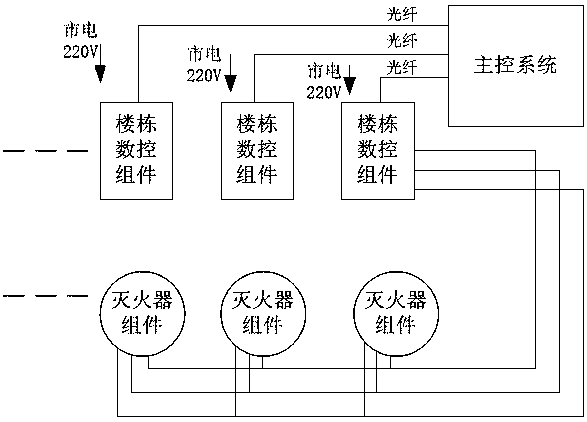

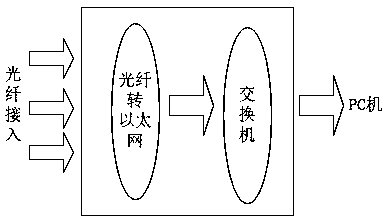

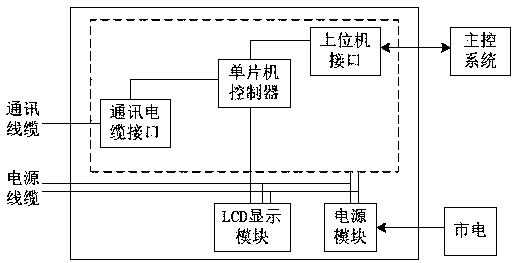

[0028] Such as Figure 1~8 As shown, a fire extinguisher management system includes: a fire extinguisher component, a building numerical control component and a main control system. The fire extinguisher component is directly connected to the pressure gauge interface of the fire extinguisher, and is responsible for collecting whether the fire extinguisher is undervoltage and the address information of the factory solidification; the building The numerical control components are connected to the fire extinguisher components, and the main control system is connected to the numerical control components of each building. The building numerical control components supply power to the fire extinguisher components through the power cable, and collect the undervoltage information and address information transmitted by each fire extinguisher component through the wired communication line, and pass RS485 The optical fiber is transferred to the main control system, and the main control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com