Slag removing device for die casting machine

A die-casting machine and frame technology, applied in mechanical cleaning, foundry equipment, manufacturing tools, etc., can solve the problems of easy occurrence of safety accidents and low efficiency of manual slag removal, so as to reduce cost, improve production efficiency, and reduce safety accidents. the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

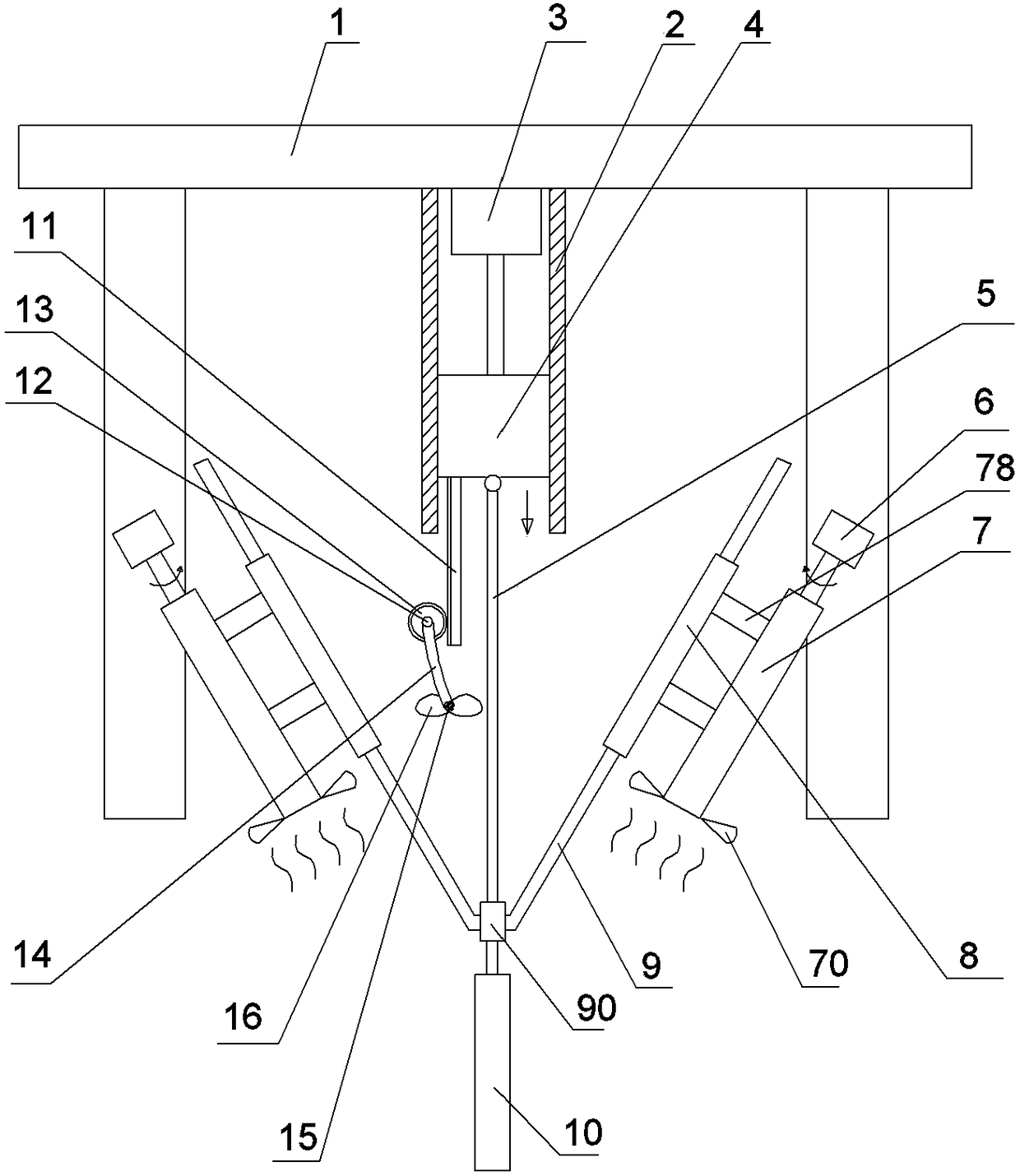

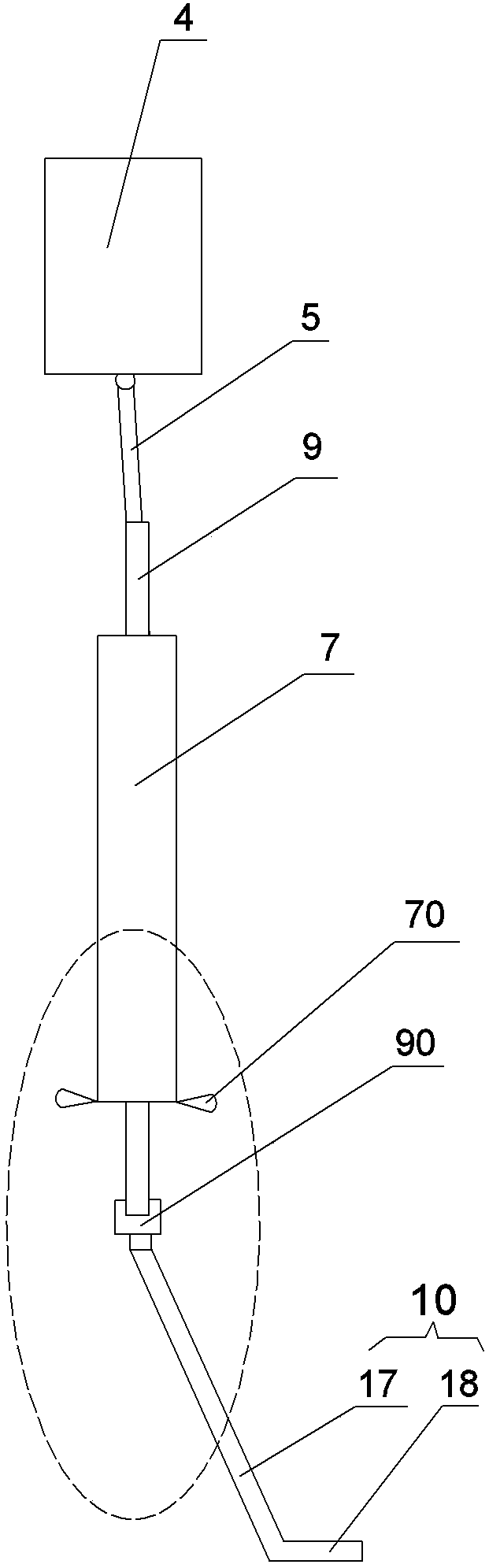

[0019] Further detailed explanation through specific implementation mode below:

[0020] The reference signs in the drawings of the description include: frame 1, chute 2, hydraulic cylinder 3, slider 4, connecting rod 5, mounting seat 6, rotating shaft 7, first paddle 70, connecting frame 78, sleeve 8 , "V" shaped frame 9, collar 90, slag removal net 10, rack 11, third rotating shaft 12, gear 13, flexible shaft 14, second rotating shaft 15, second paddle 16, steel wire mesh 17, flat plate 18 .

[0021] Such as figure 1 and figure 2 As shown, the slag removal device for die-casting machine of this embodiment includes a frame 1, two mounts 6 are fixed on the frame 1, and a first rotating shaft 7 is installed on the mounts 6 through ball bearings. The rotating shaft 7 is fixedly connected with the first paddle 70, and the outer circle of the first rotating shaft 7 is also fixed with a sleeve 8 through a connecting frame 78. The axis of the sleeve 8 is parallel to the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com