Preparation method of nano calcium carbonate

A technology of nano-calcium carbonate and inorganic calcium, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve problems such as uneven particle size and complicated process, and achieve the effect of solving pollution problems and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

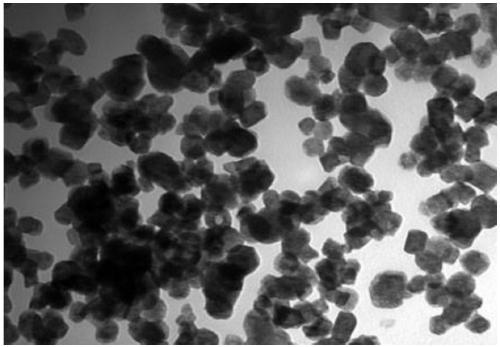

Image

Examples

Embodiment 1

[0034] A preparation method of nano-calcium carbonate, comprising the steps of:

[0035] Step 1, dissolving the water-soluble inorganic calcium salt in distilled water and ultrasonically dissolving for 30 minutes, and filtering at a constant temperature to obtain an inorganic calcium solution;

[0036] Step 2, passing ammonia gas into the inorganic calcium solution for cyclic aeration and ultrasonic reaction for 1 hour to obtain a calcium hydroxide solution;

[0037] Step 3, adding hydroxypropyl cellulose to the calcium hydroxide solution, sonicating until it is completely dispersed, and then heating and evaporating to obtain a suspension concentrate;

[0038] Step 4, adding carbon dioxide gas into the suspension concentrated liquid and circulating aeration microwave reaction for 2 hours to obtain the suspension liquid;

[0039] Step 5, the suspension is filtered to obtain a white precipitate, then soaked in anhydrous ethanol for an ultrasonic reaction for 1 hour, and after f...

Embodiment 2

[0050] A preparation method of nano-calcium carbonate, comprising the steps of:

[0051] Step 1, dissolving the water-soluble inorganic calcium salt in distilled water and ultrasonically dissolving for 60 minutes, and filtering at a constant temperature to obtain an inorganic calcium solution;

[0052]Step 2, passing ammonia gas into the inorganic calcium solution, circulating aeration and ultrasonic reaction for 3 hours, to obtain calcium hydroxide solution;

[0053] Step 3, adding hydroxypropyl cellulose to the calcium hydroxide solution, sonicating until it is completely dispersed, and then heating and evaporating to obtain a suspension concentrate;

[0054] Step 4, adding carbon dioxide gas into the suspension concentrated liquid and circulating aeration microwave reaction for 4 hours to obtain the suspension liquid;

[0055] Step 5, the suspension is filtered to obtain a white precipitate, then soaked in absolute ethanol for 3 hours of ultrasonic reaction, filtered and d...

Embodiment 3

[0065] A preparation method of nano-calcium carbonate, comprising the steps of:

[0066] Step 1, dissolving the water-soluble inorganic calcium salt in distilled water for 50 minutes, ultrasonically dissolving, and filtering at a constant temperature to obtain an inorganic calcium solution;

[0067] Step 2, passing ammonia gas into the inorganic calcium solution, circulating aeration and ultrasonic reaction for 2 hours, to obtain calcium hydroxide solution;

[0068] Step 3, adding hydroxypropyl cellulose to the calcium hydroxide solution, sonicating until it is completely dispersed, and then heating and evaporating to obtain a suspension concentrate;

[0069] Step 4, adding carbon dioxide gas into the suspension concentrated liquid and circulating aeration microwave reaction for 3 hours to obtain the suspension liquid;

[0070] Step 5, the suspension is filtered to obtain a white precipitate, then soaked in absolute ethanol for 2 hours of ultrasonic reaction, filtered and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com