PID-based double closed-loop control method for diesel-electric-fuel combined power plant

A dual closed-loop control, combined power technology, applied in the direction of propulsion unit engine, engine using propulsion unit combination, transportation and packaging, etc., can solve the problem of time-consuming and laborious gas turbine, affecting the safety of power plant, and inability to control the load of gas turbine and motor Distribution and other issues to achieve the effect of guaranteeing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

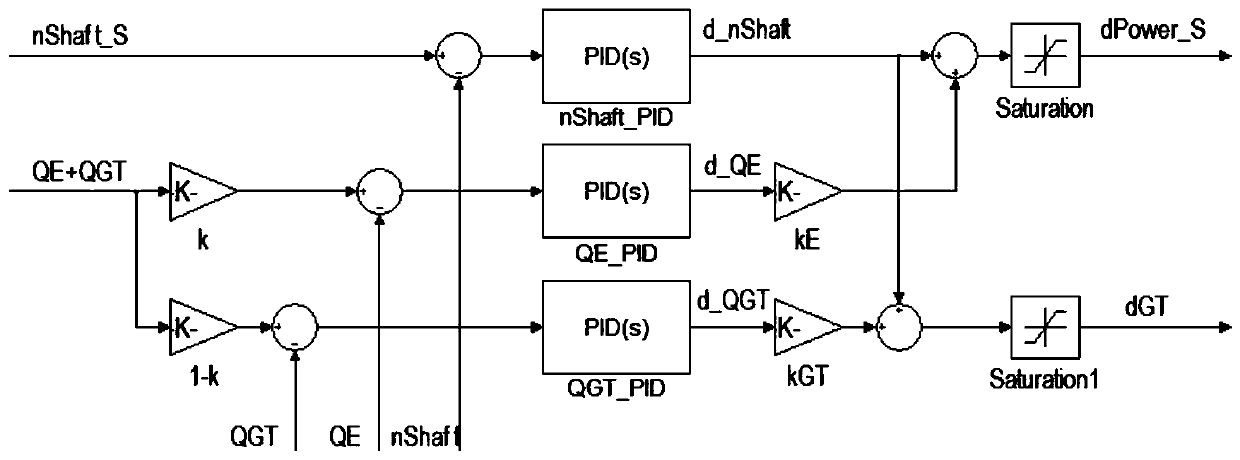

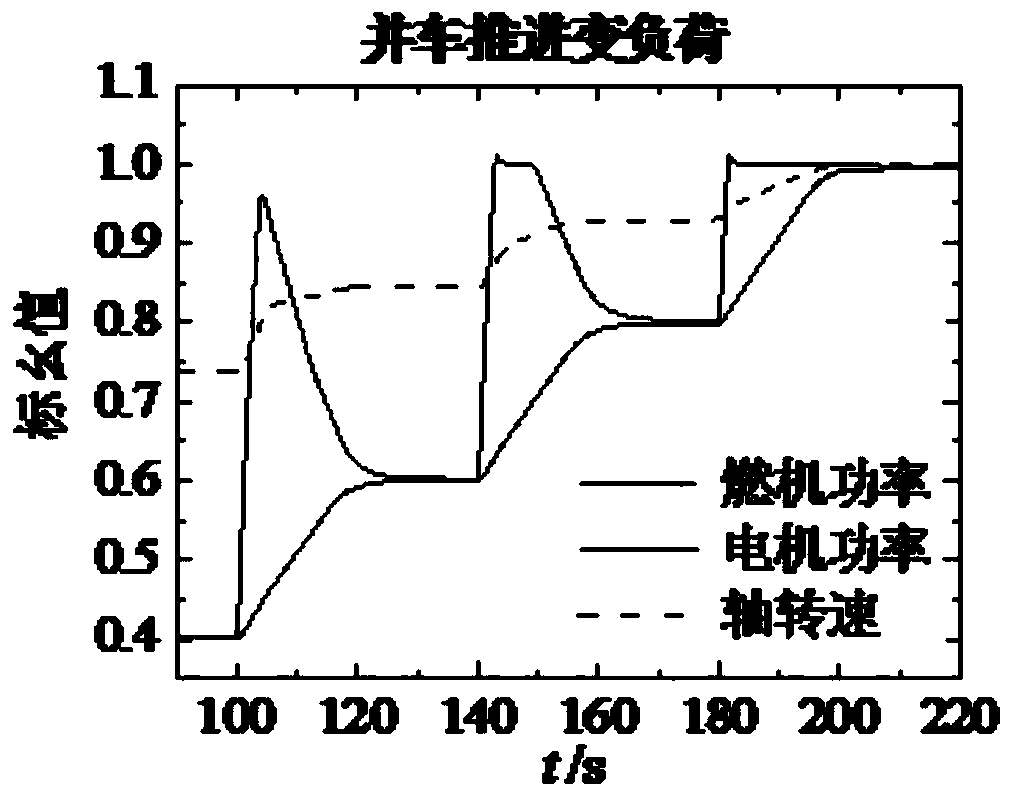

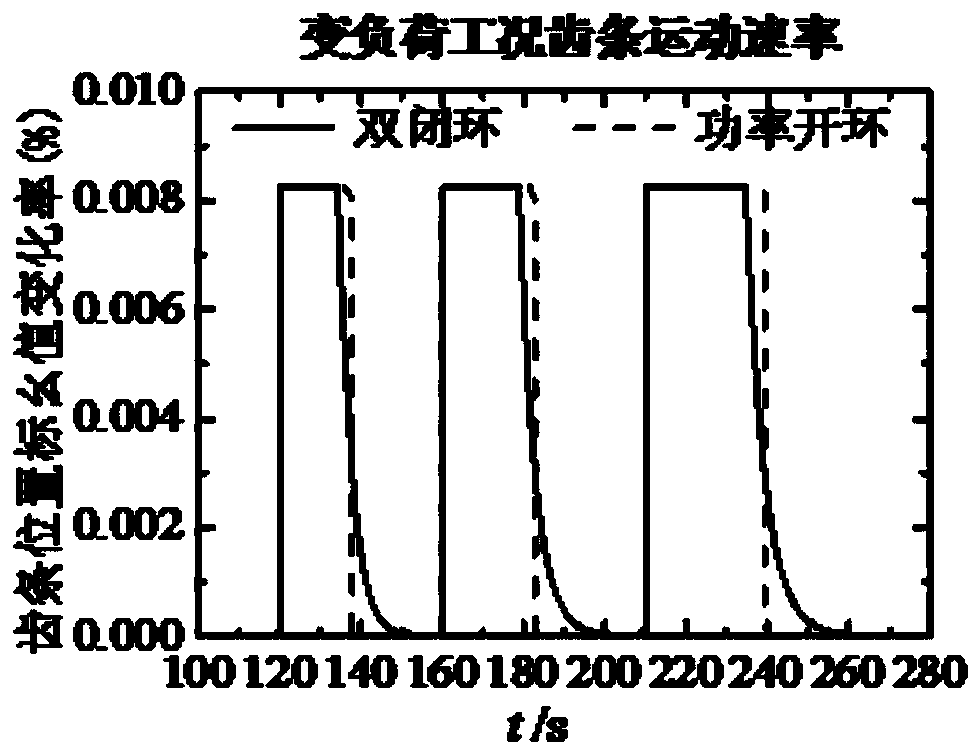

[0025] combine Figure 1-4 , the present invention adopts a PID-based double-closed-loop control method, that is, torque-shaft speed double-closed-loop. The direct output of each ring is the change rate of the controlled object, for the gas engine, it is the change rate of the fuel injection quantity, and for the electric motor, it is the change rate of the set power. Among them, the torque loop determines the change rate of the controlled object according to the preset torque distribution ratio between the gas / electric machine and the feedback torque; the shaft speed loop is determined according to the difference between the set shaft speed and the feedback shaft speed The rate of change of the controlled object. Comprehensively consider the results of the two loop feedbacks to determine the final output. At the same time, the shaft speed control and load dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com