Blend of rubber/nano-carbon material coated artificial stone polishing waste and preparation method thereof

A technology of nano-carbon material and artificial stone, which is applied to the blend of rubber/nano-carbon material coated artificial stone polishing waste and the field of preparation thereof, and achieves the effects of high surface activity, cost reduction and stiffness improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

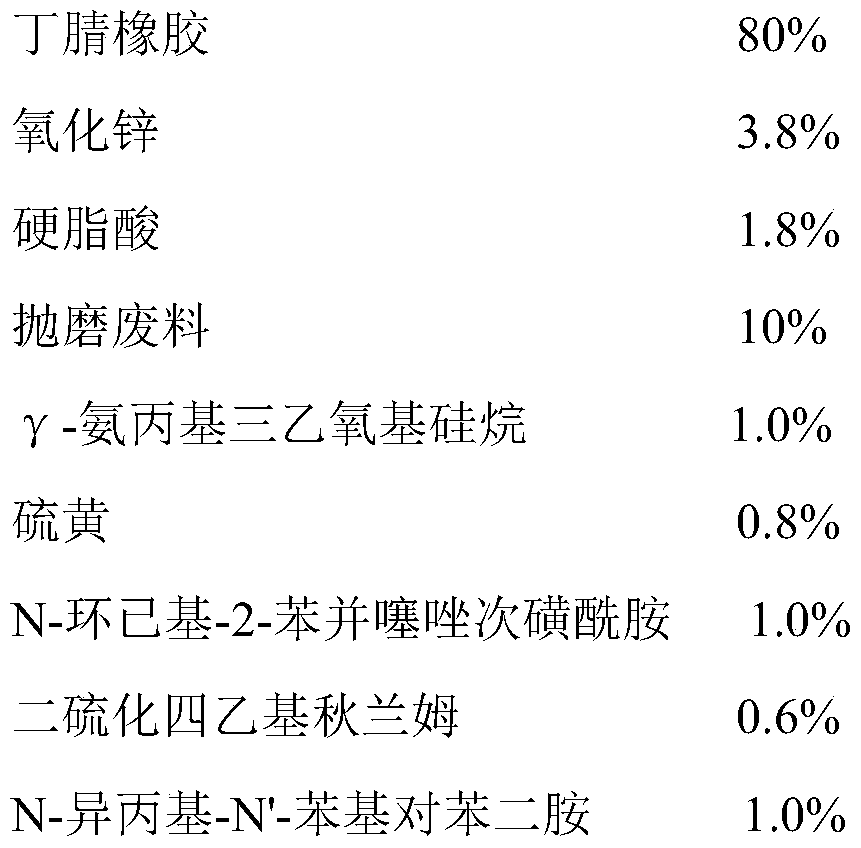

[0046] In terms of mass percentage, the consumption of each raw material is as follows:

[0047]

[0048]

[0049] Mix artificial stone polishing waste and water at a mass ratio of 1:2, stir for 1 hour, and rotate at a speed of 600r min -1 Obtain a suspension of polishing waste, then add graphene oxide into deionized water, stir for 1h, and rotate at a speed of 600r min -1 , ultrasonically dispersed for 2h, made into 5wt% graphene oxide aqueous dispersion, then the graphene oxide aqueous dispersion was added in the polishing waste suspension, wherein the mass ratio of graphene oxide and polishing waste was 1:20, stirring 1h, speed 600r·min -1 , so that graphene oxide is evenly coated on the surface of the polishing waste, the polishing waste is left to stand, suction filtered, and moisture is removed, and then the polishing waste is dried in an oven under the condition of 90 ° C × 2h to obtain graphene oxide Coated polishing waste;

[0050] The nitrile rubber is masti...

Embodiment 2

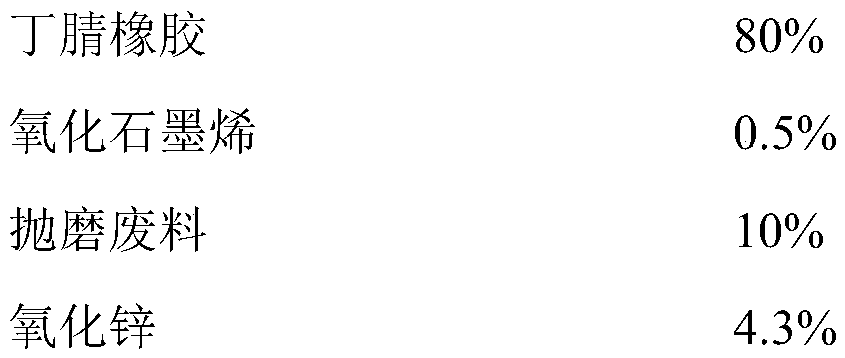

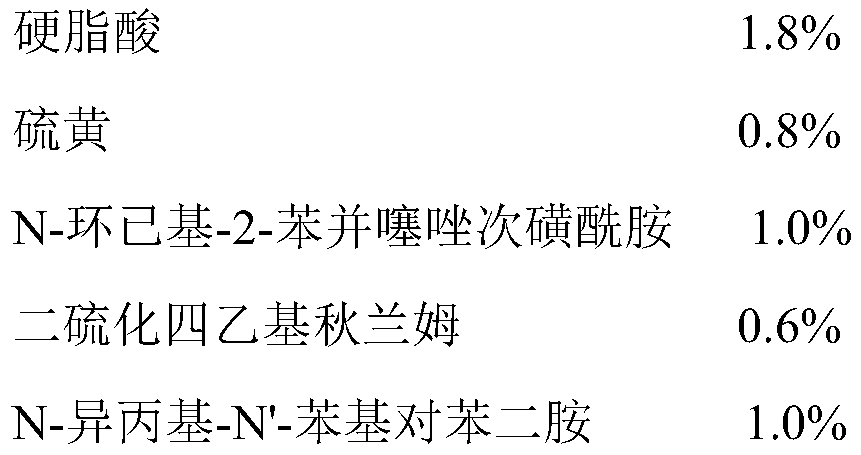

[0052] In terms of mass percentage, the consumption of each raw material is as follows:

[0053]

[0054] Mix artificial stone polishing waste and water at a weight ratio of 1:2, stir for 2 hours, and rotate at a speed of 300r min -1 , to obtain a suspension of polishing waste, then add graphene oxide into deionized water, stir for 2 hours, and rotate at a speed of 600r·min -1 , ultrasonically dispersed for 3h, made into a 5wt% graphene oxide water dispersion, and then the water dispersion was added to the polishing waste suspension, wherein the mass ratio of graphene oxide and polishing waste was 1:30, stirred for 2h, and the speed 600r·min -1 , so that graphene oxide is evenly coated on the surface of the polishing waste, the polishing waste is left to stand, suction filtered, and moisture is removed, and then the polishing waste is dried in an oven under the condition of 90°C×4h to obtain graphene oxide Coated polishing waste;

[0055] The nitrile rubber is masticated...

Embodiment 3

[0057] In terms of mass percentage, the consumption of each raw material is as follows:

[0058]

[0059] Mix artificial stone polishing waste and water at a mass ratio of 1:2, stir for 1 hour, and rotate at a speed of 600r min -1 , to obtain a suspension of polishing waste, and then add graphene to deionized water, stir for 2h, and rotate at a speed of 600r·min -1 , ultrasonic dispersion 3h, be made into 5wt% graphene aqueous dispersion, then water dispersion is added in the polishing waste suspension, wherein the mass ratio of graphene and polishing waste is 1:20, stirs 1h, rotating speed 600r· min -1 , let graphene evenly cover the surface of the polishing waste, put the polishing waste to stand, suction filter, remove water, and then dry the polishing waste in an oven under the condition of 90 ° C × 2h, to obtain graphene coating Repolishing waste;

[0060] The nitrile rubber is masticated with a rubber internal mixer, and the rotor speed is 40r min -1 , add graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com