Hydrolysis saccharification process of alternanthera philoxeroides

A hollow lotus seedling and process technology, applied in the direction of fermentation, etc., can solve the problem of low final reducing sugar production, achieve the effects of reducing energy consumption, improving treatment rate, and high glucose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

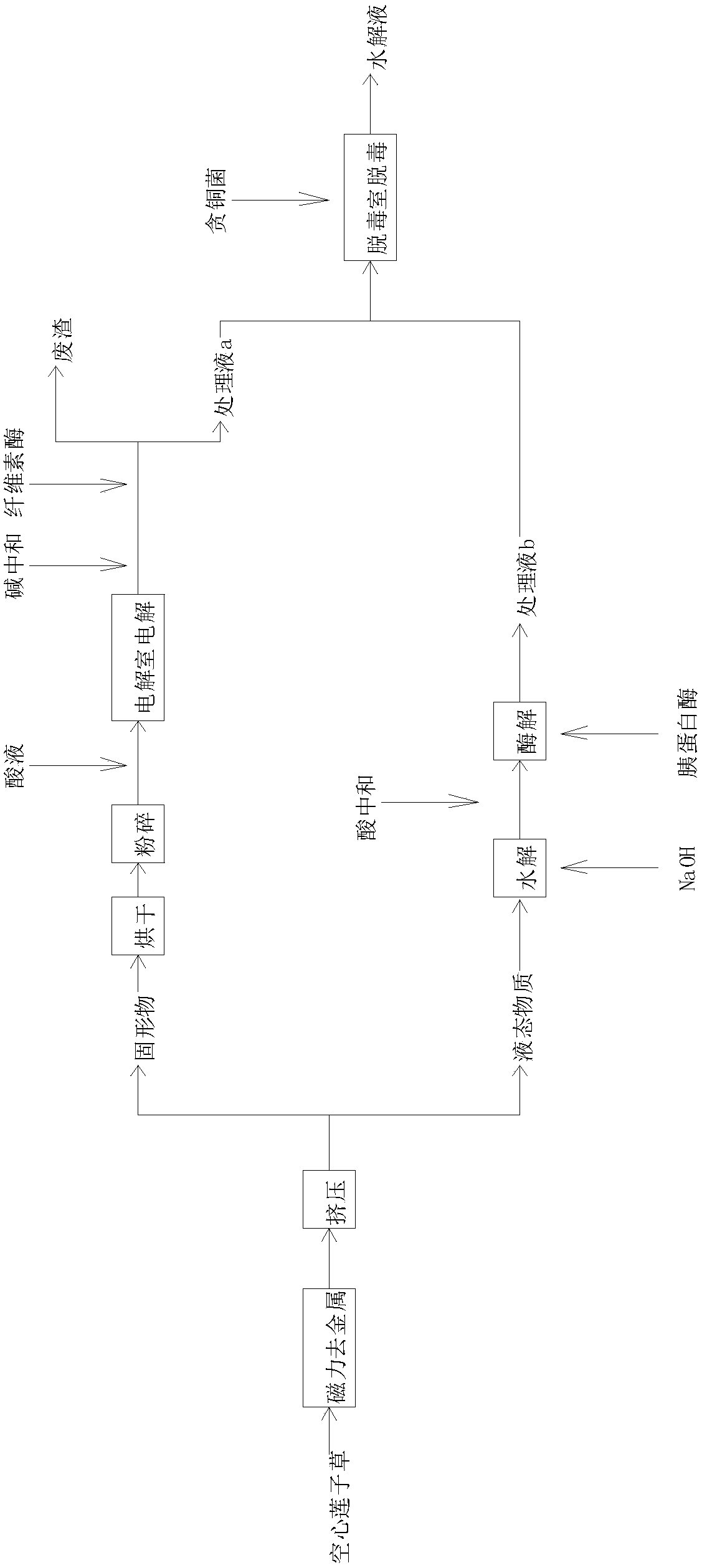

[0028] The hydrolysis and saccharification process of Asteroides spinosa described in the present embodiment specifically comprises the following steps:

[0029] (1) Choose 500g Hollow Lotus Seed Grass as raw material, put the Hollow Lotus Seed Grassland material into the drum sieve with several bar magnets distributed in parallel on the inner wall of the drum, open the drum sieve to remove impurities and metal, rotate for 30min, and collect the hollow lotus seeds Grass raw material, and then put the collected hollow lotus grass raw material into the press to realize solid-liquid separation, and obtain solid and liquid substances;

[0030] (2) After drying and pulverizing the solid obtained in step (1), drop into an electrolytic cell filled with sulfuric acid solution (concentration is 2%) and stir and dissolve to form a solution. Two carbon electrodes are arranged in the electrolytic cell, and the carbon The electrode power supply is used to treat the solution in the electrol...

Embodiment 2

[0034] The hydrolysis and saccharification process of Asteroides spinosa described in the present embodiment specifically comprises the following steps:

[0035] (1) Choose 500g Hollow Lotus Seed Grass as raw material, put the Hollow Lotus Seed Grassland material into the drum sieve with several bar magnets distributed in parallel on the inner wall of the drum, open the drum sieve to remove impurities and metal, rotate for 30min, and collect the hollow lotus seeds Grass raw material, and then put the collected hollow lotus grass raw material into the press to realize solid-liquid separation, and obtain solid and liquid substances;

[0036] (2) After drying and pulverizing the solid obtained in step (1), drop into an electrolytic tank filled with sulfuric acid solution (concentration is 1.5%) and stir and dissolve to form a solution. Two carbon electrodes are arranged in the electrolytic tank, and the carbon The electrode power supply is used to treat the solution in the electr...

Embodiment 3

[0040] The hydrolysis and saccharification process of Asteroides spinosa described in the present embodiment specifically comprises the following steps:

[0041] (1) Choose 500g Hollow Lotus Seed Grass as raw material, put the Hollow Lotus Seed Grassland material into the drum sieve with several bar magnets distributed in parallel on the inner wall of the drum, open the drum sieve to remove impurities and metal, rotate for 30min, and collect the hollow lotus seeds Grass raw material, and then put the collected hollow lotus grass raw material into the press to realize solid-liquid separation, and obtain solid and liquid substances;

[0042] (2) After drying and pulverizing the solid matter obtained in step (1), drop into an electrolytic cell filled with sulfuric acid solution (concentration is 1%) and stir and dissolve to form a solution. Two carbon electrodes are arranged in the electrolytic cell, and the carbon The electrode power supply is used to treat the solution in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com