a cable device

A technology of steel cables and support rods, which is applied in the directions of transportation and packaging, cable cranes, erection/assembly of bridges, etc., and can solve the problems of worn reference steel cables, inability to adjust the supporting cable device at the crossing point of the steel cable, and shaking of the supporting cable device. Achieve the effects of improving service life, avoiding artificial high-altitude operations, and smooth climbing and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

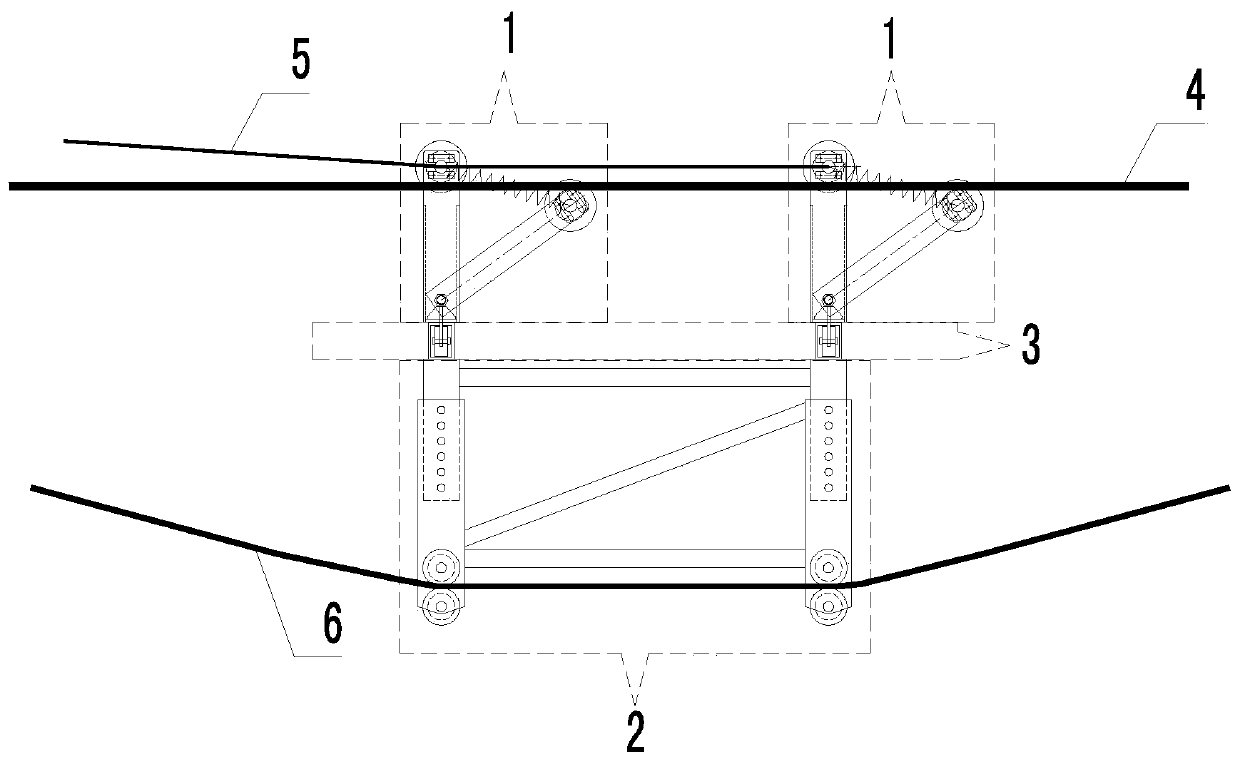

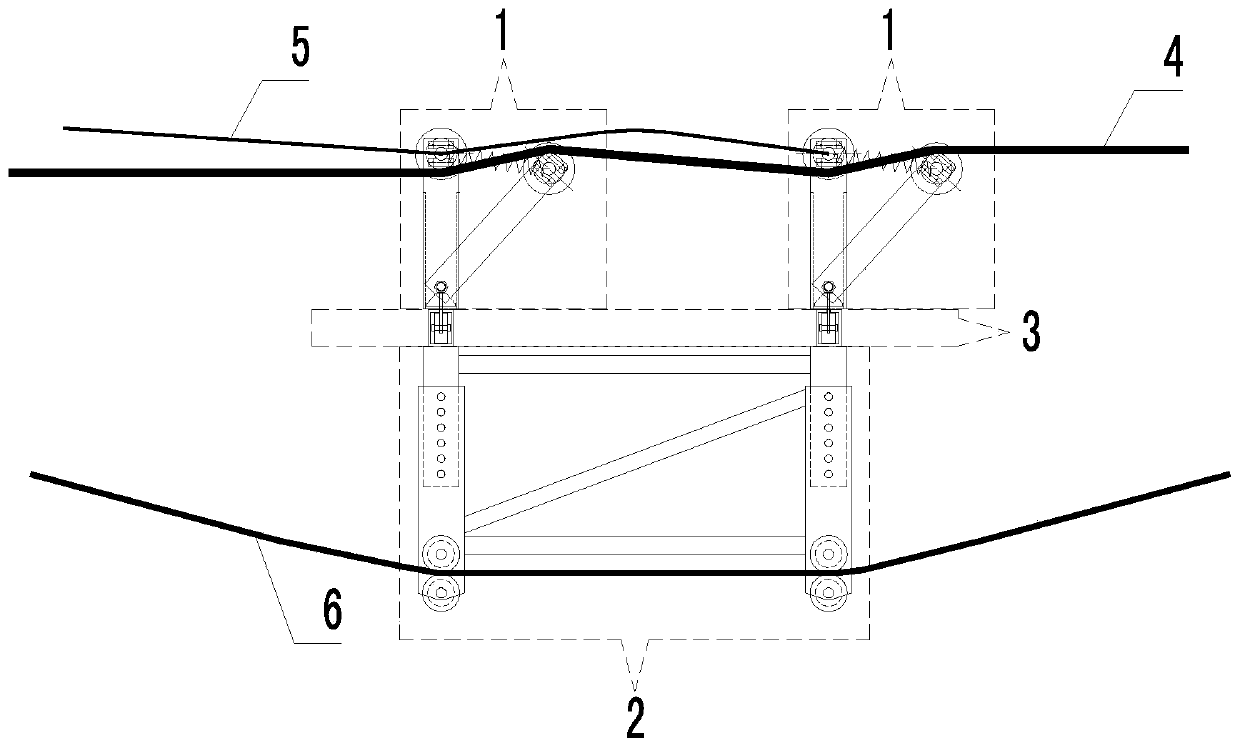

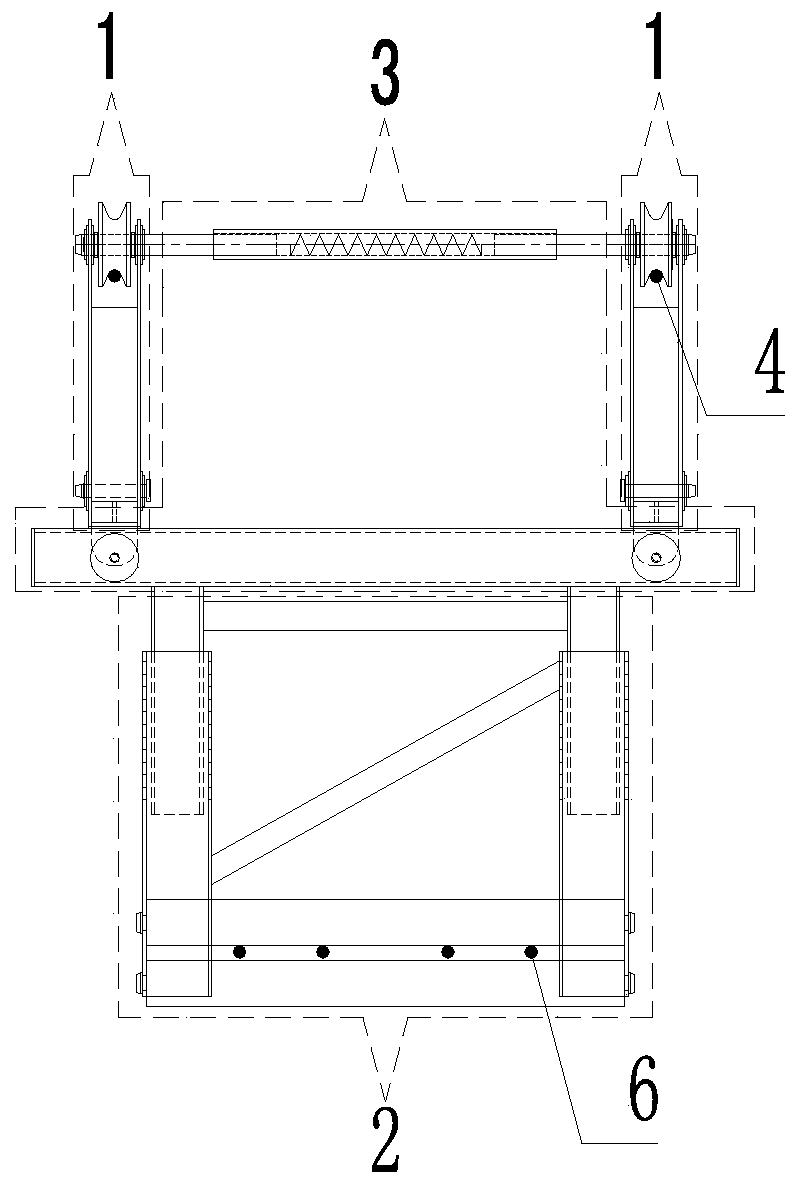

[0039] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a kind of support cable device, and it is used for propping up reference cable 4 and target cable 6, and it comprises support cable system 2, at least two climbing fixing systems 1 and traction system; Support cable system 2. It is used to be actively assembled on the target cable 6. The support cable system 2 can move along the extending direction of the target cable 6, and can also limit the target cable 6 to prevent the target cable 6 from being separated from the support cable system 2 due to swing. ; Two climbing and fixing systems 1 are arranged on the support cable system 2 at intervals along the extension direction perpendicular to the reference steel cable 4, and the climbing and fixing systems 1 are in groups of two, and multiple groups can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com