Method for reinforcing rock-fill dam concrete face through ultra high toughness cementitious composites

A technology for concrete panels with ultra-high toughness, applied in the direction of dams, barrages, weirs, etc., can solve the problems of panel cracking, unchanged quasi-brittle material properties of concrete materials, limited crack resistance, etc., to prevent cracking and deformation of components Coordinating and improving the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

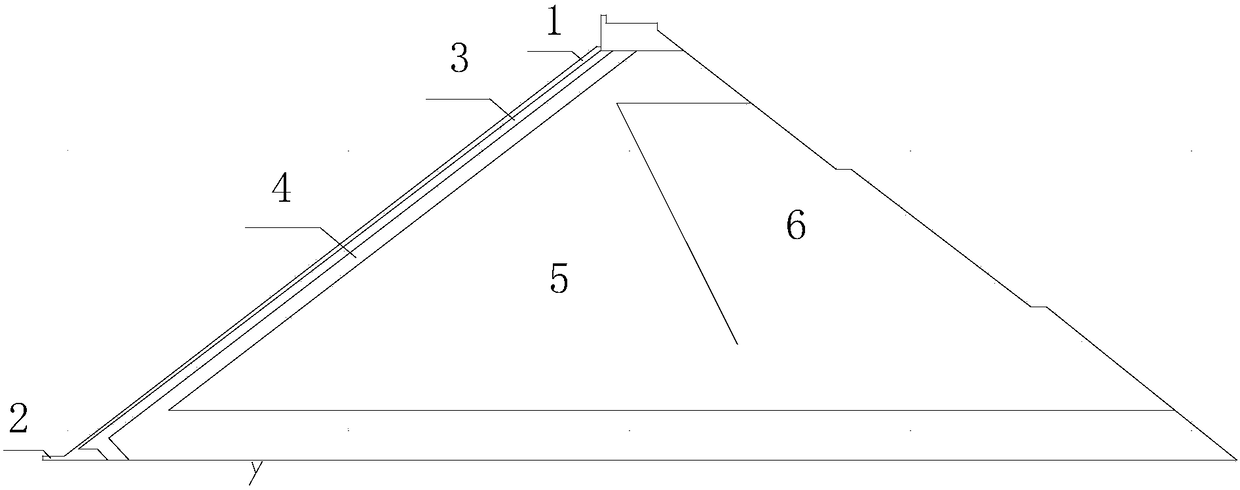

[0029]The barrage is a reinforced concrete face rockfill dam, the width of the river valley is about 140m~150m, and the ground elevation of the riverbed section is 50m~55m. The concrete face dam is a Class 2 structure, designed according to the flood once in 200 years, and checked for the flood once in 5,000 years. The dam crest elevation is 106.00m, the maximum dam height is 64.00m, the dam crest length is 290.00m, the dam crest width is 8.00m, and the upstream and downstream slopes are 1:1.3. The downstream dam slopes are respectively provided with horse tracks at elevations 85.00m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com