w-shaped steel sheet pile structure

A steel sheet pile and section steel technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high construction cost of cast-in-place piles, discharge of soil slag or mud, and underground pollution, etc. Small residual stress and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The construction process of W-shaped steel sheet pile and rotary grouting cable-stayed string anchor cable:

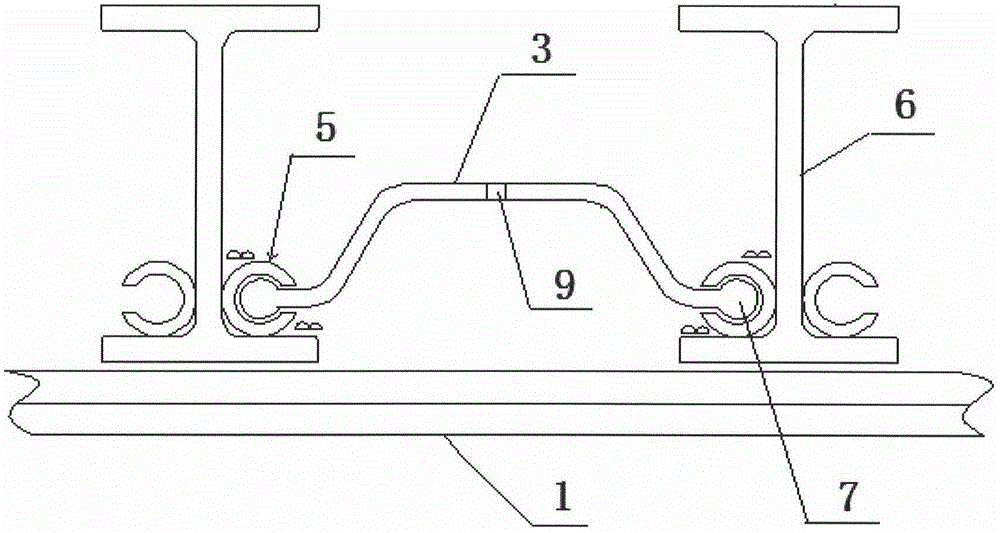

[0033] like Figure 5 , first measure and set out, check the steel sheet pile, position the guide beam, make the guide beam, insert and drive the W-shaped steel sheet pile, pump and excavate the foundation pit, and then start the construction of the rotary grouting anchor cable, passing the anchor cable hole on the U-shaped steel , implement high-pressure rotary grouting anchor cables, form string anchor cables through pressure adjustment and lifting speed, install waist beams, etc., seal the bottom with concrete, pour caps, finally remove anchor cables at waist beams, and remove steel sheet piles. According to the above workflow, According to the size of the pit foundation, different numbers of W-shaped steel sheet piles, waist beam 1 and waist beam support 2, as well as the number of layers of the cable-stayed anchor cable and the anchor rod 4 can be selected....

Embodiment 2

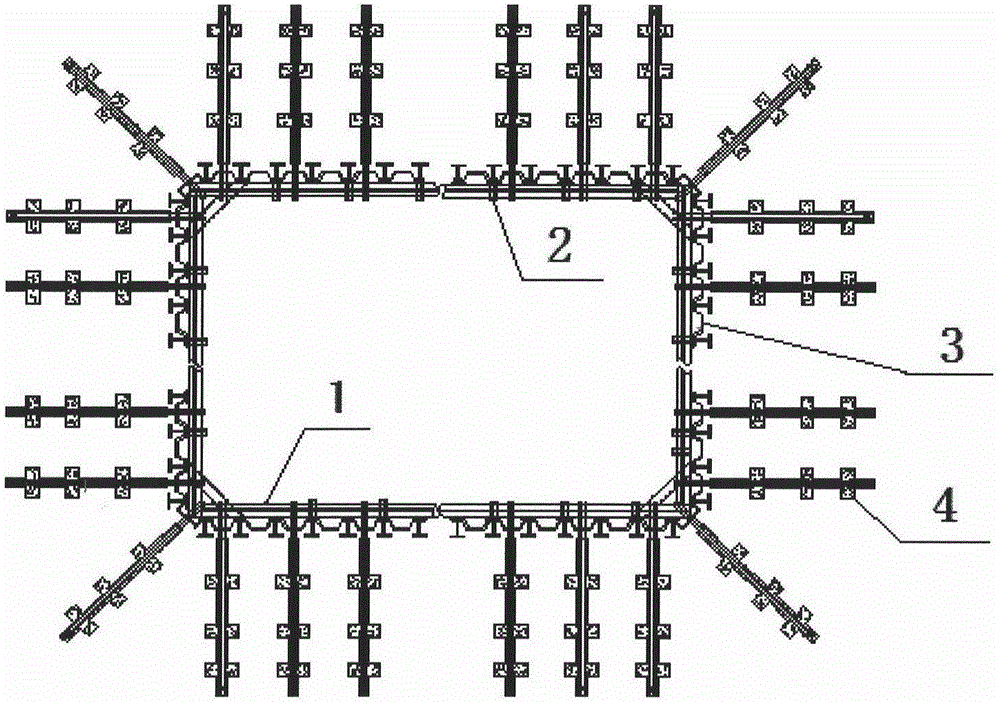

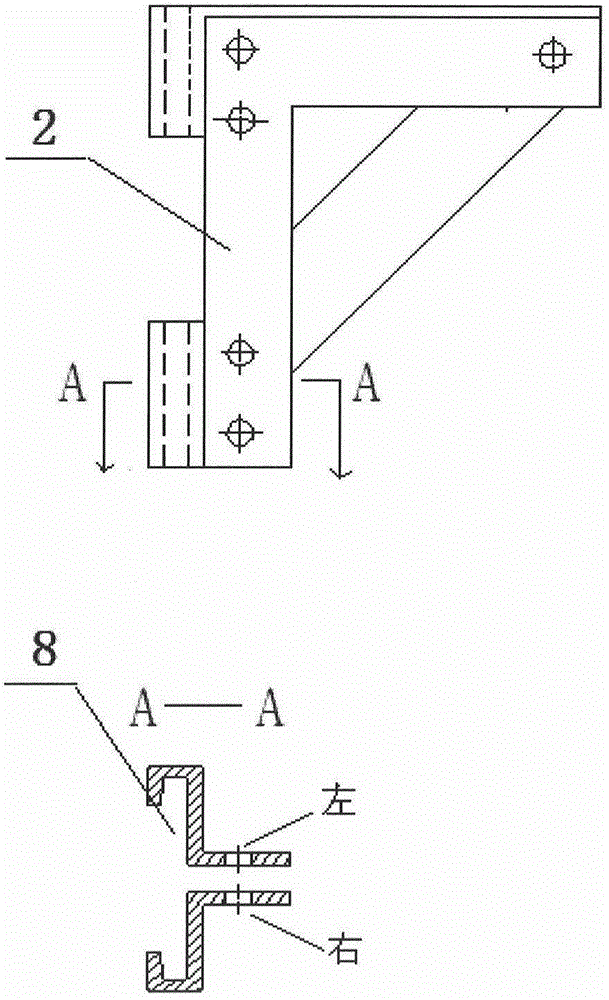

[0035] W-shaped steel sheet piles can be used in combination with existing internal support structures such as Figure 4 As shown, a number of W-shaped steel sheet piles form a closed foundation pit. Triangular plates 13 are arranged on the four corners of the foundation pit. The beams 11 and longitudinal beams 10 in the pit foundation are arranged perpendicular to each other. The waist beam 1 is fixedly connected, and the waist beam support 2 is arranged below the waist beam 1. The waist beam support 2 is a left and right combination type, and a diagonal brace 12 is provided on the adjacent side of the pit foundation.

[0036] like Figure 6 As shown, first measure and set out, check the steel sheet pile, position the guide beam, make the guide beam, insert and drive the W-shaped steel sheet pile, pump and excavate the foundation pit, then install the inner support of the waist beam, seal the bottom with concrete, and pour the cap , and finally the waist beam anchor cable is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com