Ground overhead system and mounting method thereof

An installation method and ground technology, applied to floors, local raised floors, buildings, etc., can solve the problems of high difficulty in controlling the gaps in floor tile paving, difficult ground leveling process, and high material consumption, so as to improve the installation quality , shorten the paving hours, improve the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

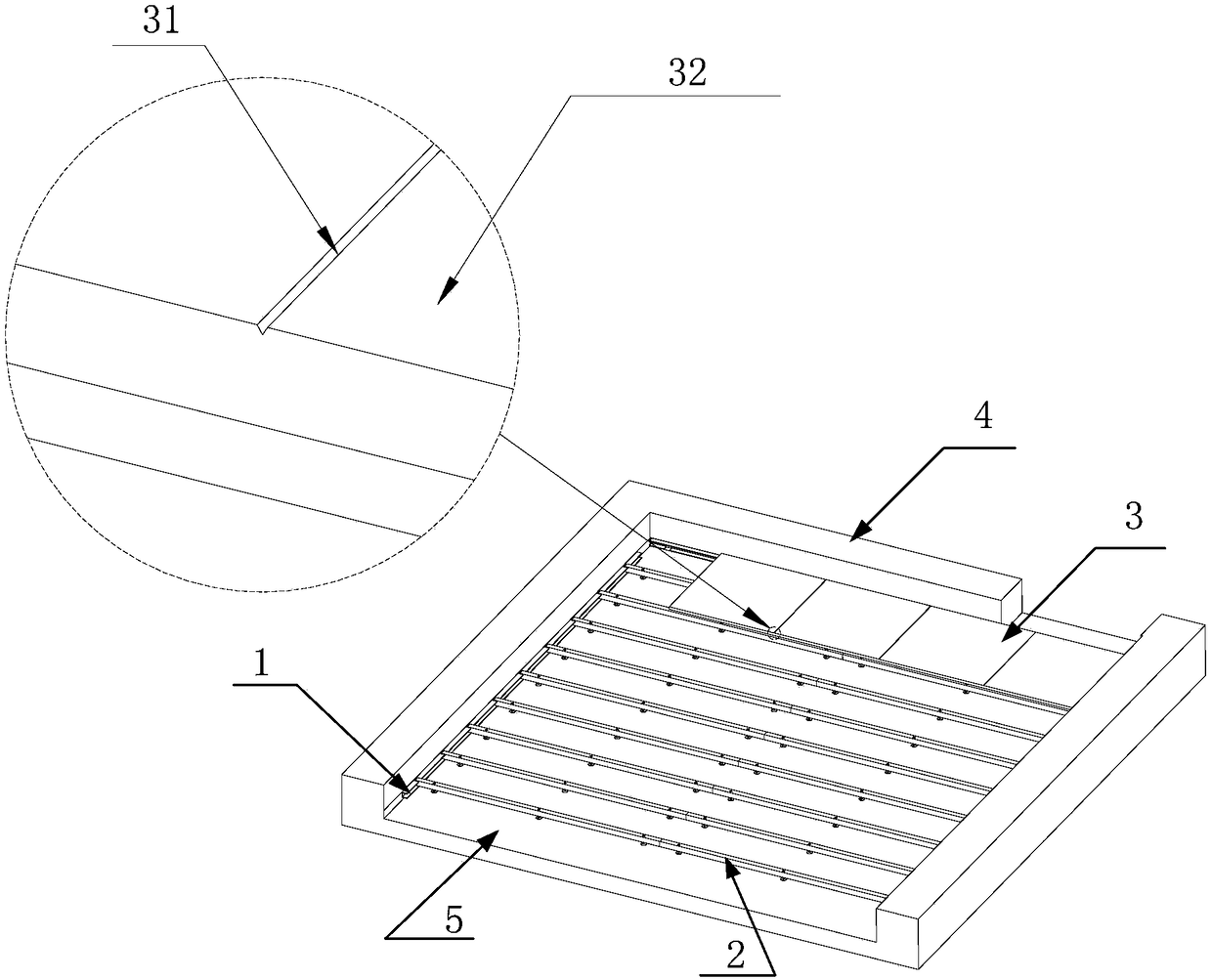

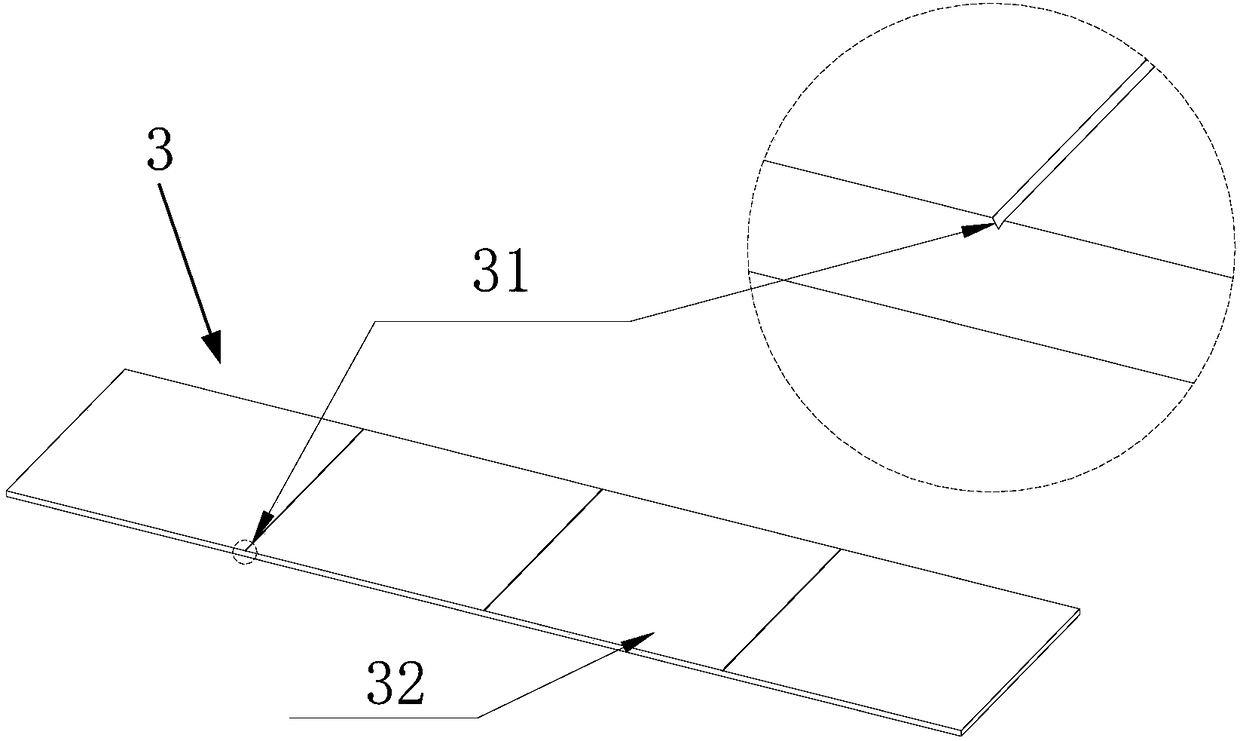

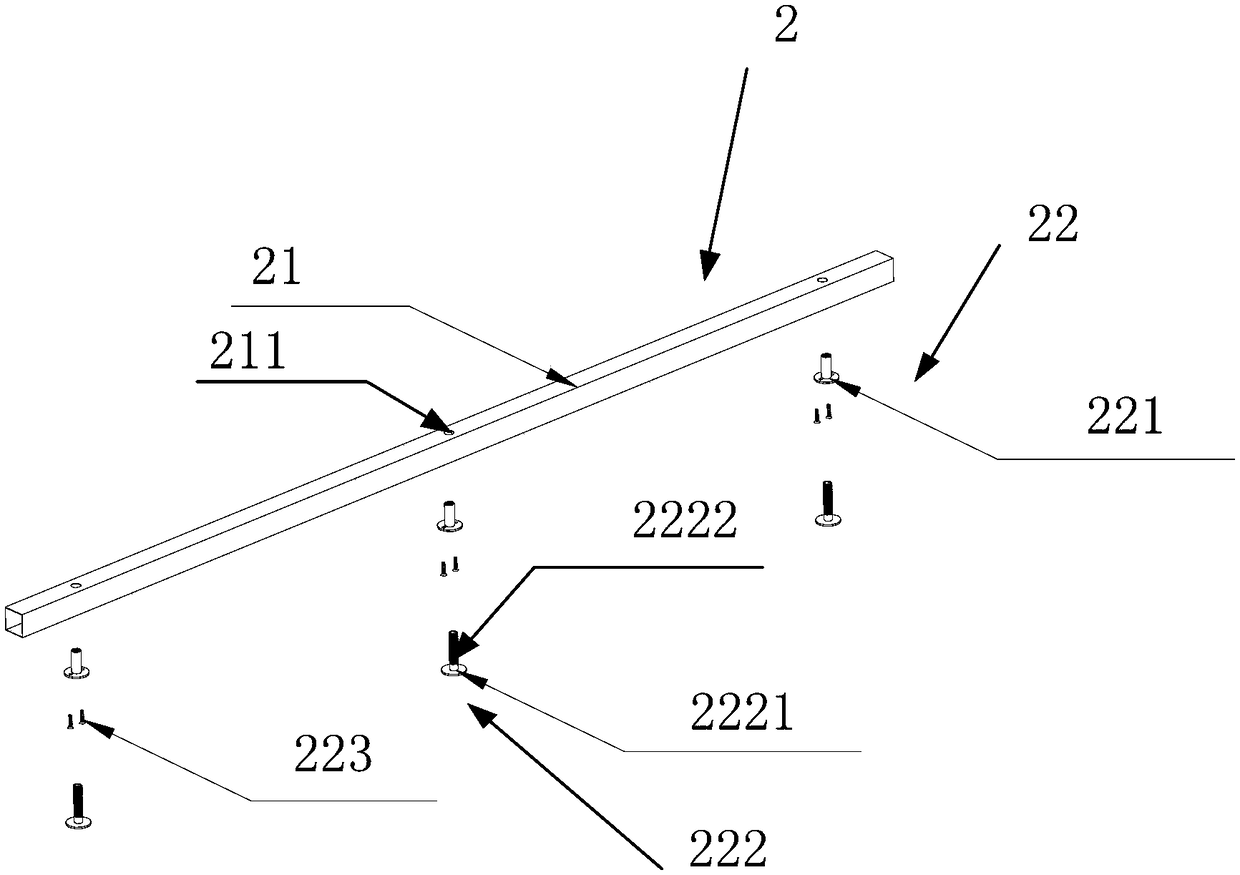

[0034] like figure 1 Shown is a structural schematic diagram of a ground overhead system of the present invention, including: a wall leveling module 1 installed on the wall 4, one or more wall leveling modules mounted on the wall leveling module 1 that can be independently adjusted to the ground 5 The height leveling load-bearing module 2, and one or more finish layer modules 3 paved on the leveling load-bearing module 2, and each of the finish layer modules 3 is provided with one or more false seams 31.

[0035] Specifically, the wall surface leveling module 1 and the leveling load-bearing module 2 form a load-bearing frame, and the decorative surface layer module 3 is laid on the leveling load-bearing module 2 . Due to the false seam provided on the facing layer module 3, the false seam refers to a seam that does not penetrate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com