A life-cycle cost assessment method for cable line steel support based on thermal fatigue

A full-life cycle, cable line technology, applied in electrical digital data processing, instruments, data processing applications, etc., can solve problems such as bracket heating, steel bracket fatigue damage, and increase cable line operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

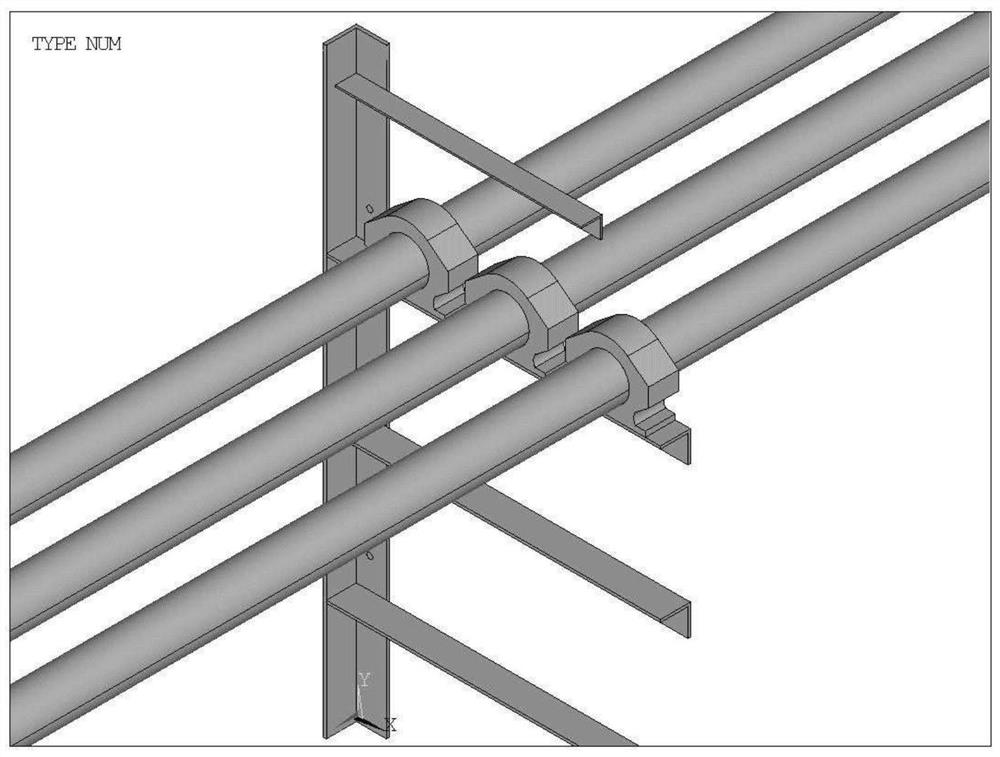

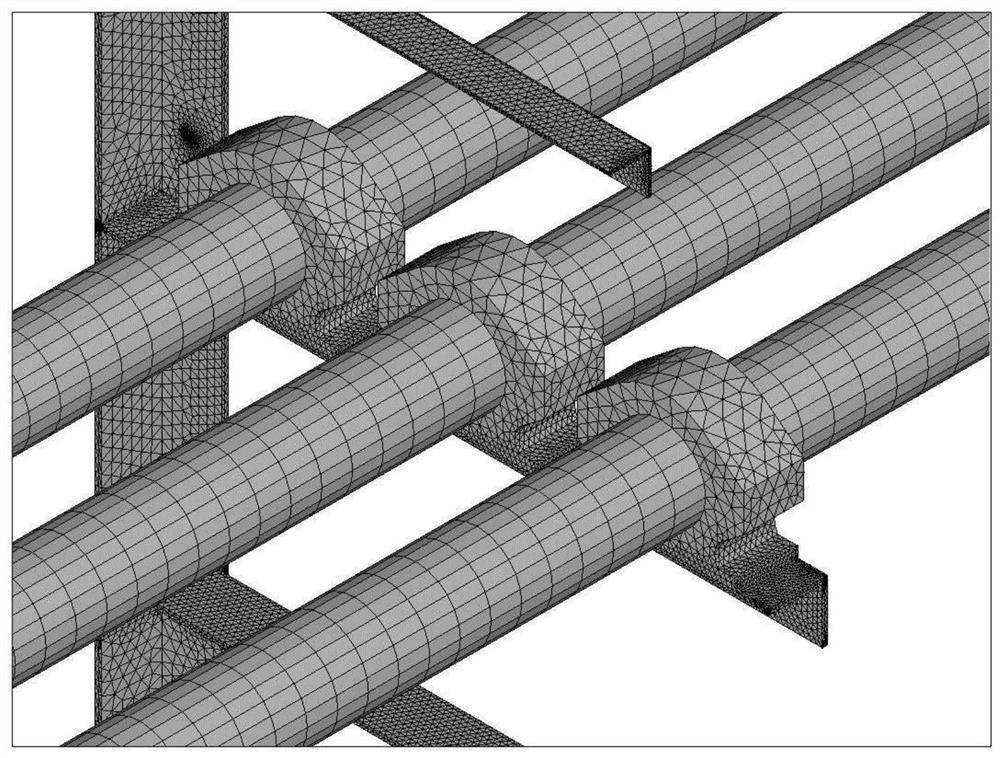

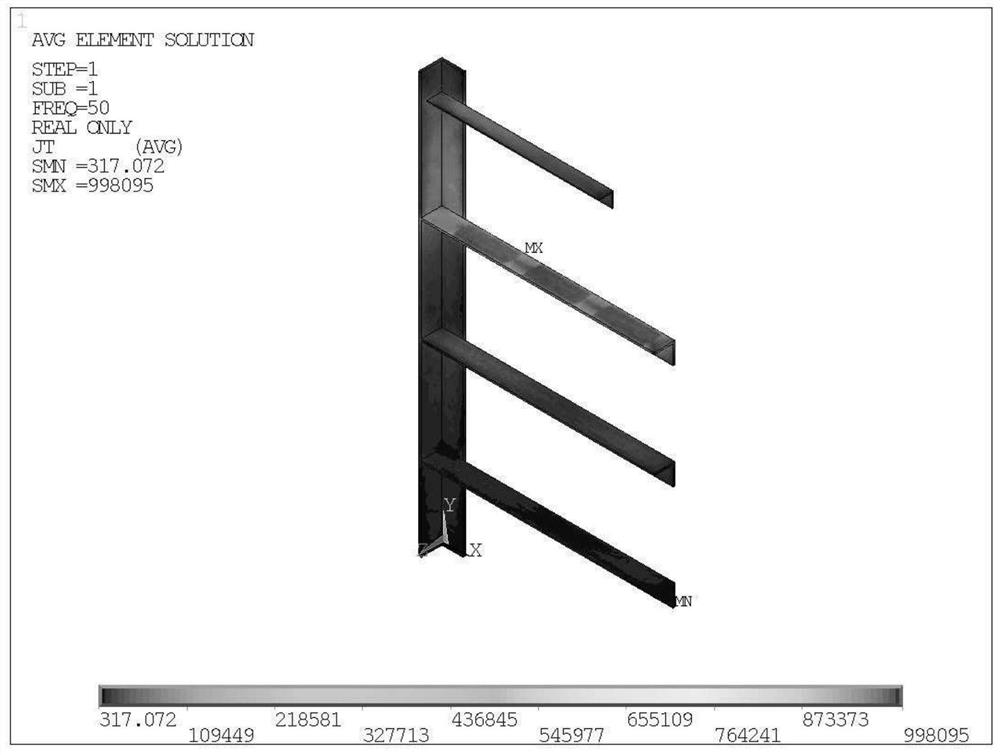

[0048] A life-cycle cost assessment method for cable line steel support based on thermal fatigue. According to the three-dimensional model of the cable line in the cable tunnel, the electromagnetic field is calculated by the finite element method to obtain the eddy current loss on the steel support, and then through the electromagnetic field and flow field, temperature The coupling numerical calculation of the field is used to obtain the temperature change on the steel bracket, and the fatigue life of the steel bracket is calculated considering the fatigue damage of the steel bracket caused by the cyclical thermal stress. The whole life cycle cost model of the cable steel support is established. The parameters in the model include the operating cost of the steel support eddy current loss obtained from the calculation of the electromagnetic field, and the service life is the fatigue life period obtained from the thermal fatigue analysis.

[0049] Specifically include the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com