Multi-sensor online liquor picking system with liquid level control function

A multi-sensor and temperature sensor technology, applied in the field of multi-sensor online wine picking system, can solve the problems of poor reliability, great influence of hops, low detection accuracy, etc., achieve good accuracy, compact and reasonable structure layout, and reduce the impact of raw wine flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but this does not limit the protection scope of the present application.

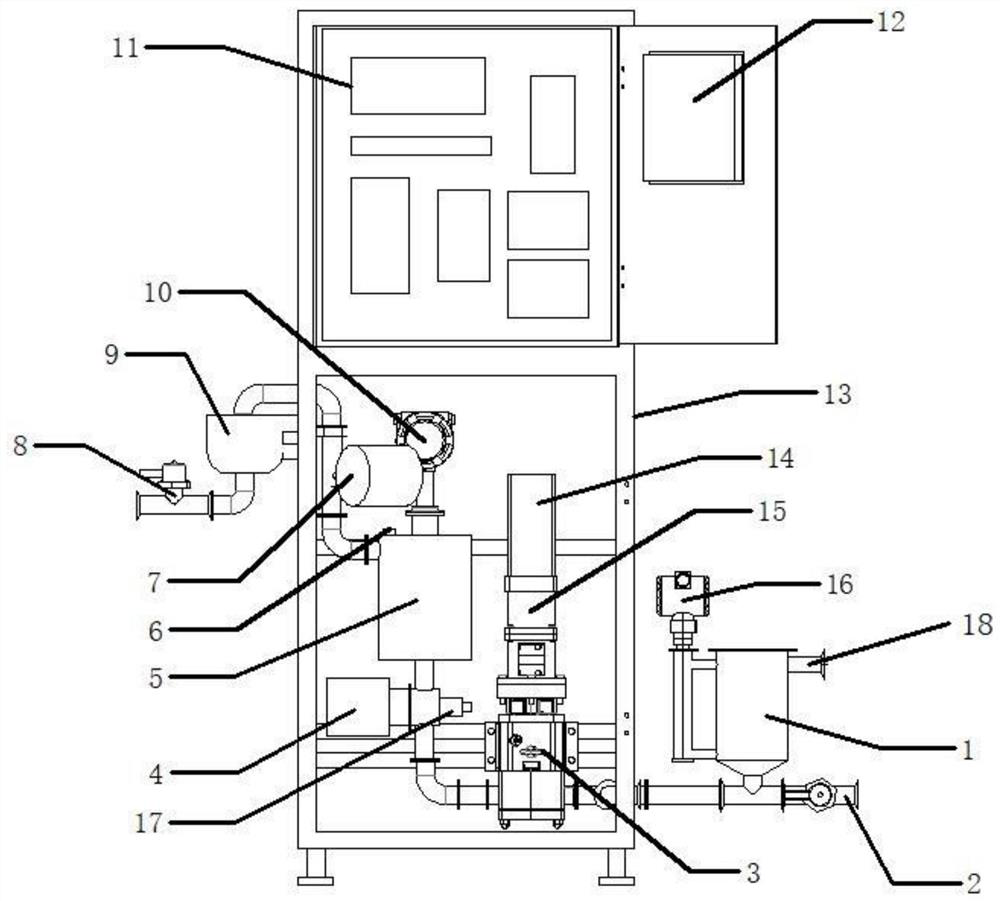

[0023] like figure 1 As shown in the figure, the present invention is a multi-sensor online wine picking system (referred to as the system) with liquid level control, including a wine collector 1, a raw wine lift pump 3, a refractometer 4, a wine quality information collector 5, a temperature Sensor 6, tuning fork density sensor 10, flow sensor 7, power motor 14, reducer 15, liquid level sensor 16 and No. 2 temperature sensor 17;

[0024] The inlet of the upper part of the wine collector 1 leads to the original wine cooled by the condenser, the outlet of the lower part of the wine collector 1 is connected to the pumping end of the original wine lifting pump 3, and the pump outlet of the original wine lifting pump 3 is connected to the wine quality information collection. d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com