Electrolytic capacitor sealing machine

An electrolytic capacitor and sealing machine technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as poor sealing and unstable operation of capacitors, and achieve the effects of reducing poor product sealing, improving product quality, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

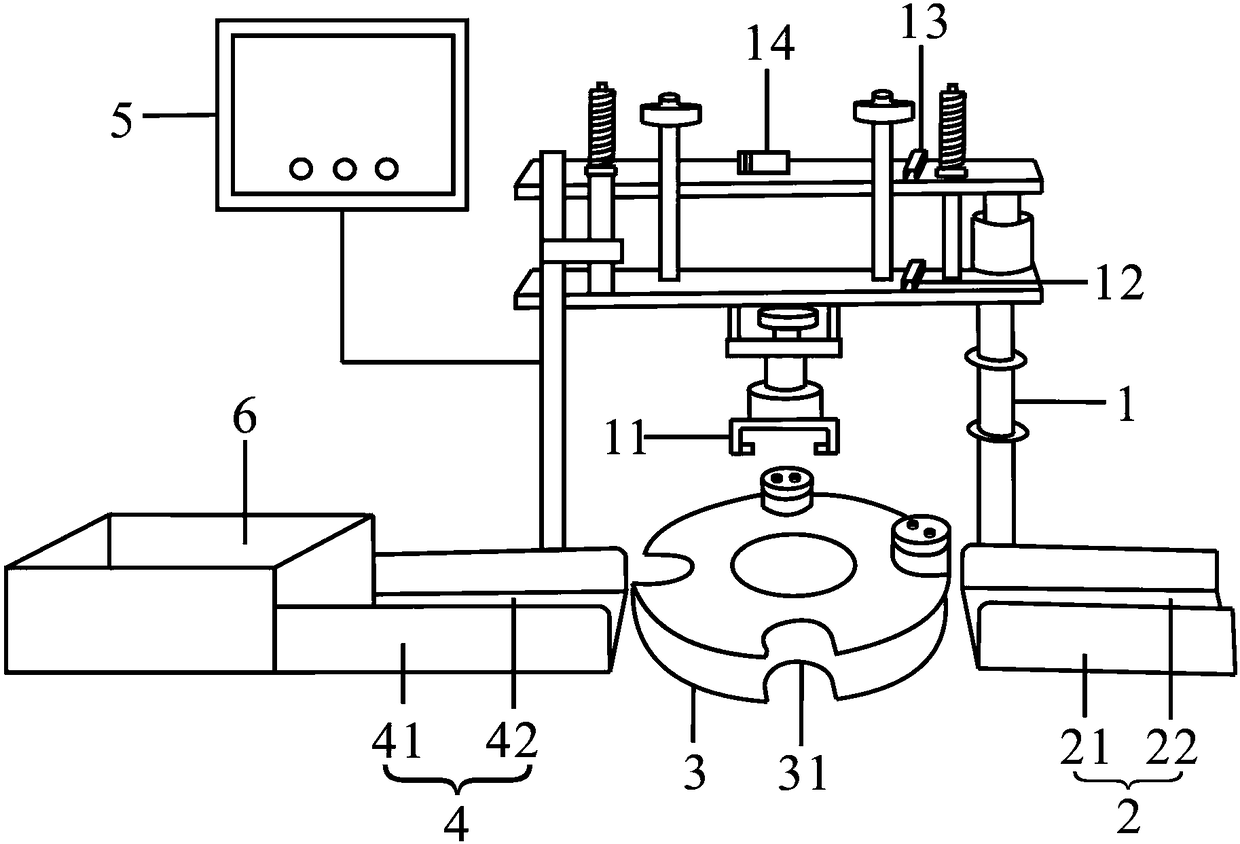

[0024] see figure 1 ,Such as figure 1 As shown, the present invention discloses an electrolytic capacitor sealing machine, which is used to automatically seal electrolytic capacitors to be sealed, including a frame 1, a conveying mechanism 2, a rotating disk 3, an output mechanism 4, a control unit 5 and an electrolytic capacitor collecting table 6. The frame 1 is provided with a sealing fixture 11, the sealing fixture 11 is used to clamp and seal the electrolytic capacitor, the rotating disk 3 is arranged directly under the sealing fixture 11, and the rotating The disc 3 is used to rotate the electrolytic capacitor on the conveying mechanism 2 to directly below the sealing fixture 11, the conveying mechanism 2 and the output mechanism 4 are respectively arranged on both sides of the rotating disc 3, the control unit 5 and the The rack 1 is electrically connected. The control unit 5 is a PLC controller.

[0025] The frame 1 is also provided with a pneumatic cylinder 12, a h...

Embodiment 2

[0030] The invention discloses an electrolytic capacitor sealing machine, which is used for automatic sealing of electrolytic capacitors to be sealed, comprising a frame 1, a conveying mechanism 2, a rotating disk 3, an output mechanism 4, a control unit 5 and an electrolytic capacitor collecting table 6. The frame 1 is provided with a sealing jig 11, the sealing jig 11 is used to clamp and seal the electrolytic capacitor, the rotating disc 3 is arranged directly below the sealing jig 11, and the rotating disc 3 is used for When the electrolytic capacitor on the conveying mechanism 2 is rotated to directly below the sealing fixture 11, the conveying mechanism 2 and the output mechanism 4 are respectively arranged on both sides of the rotating disk 3, the conveying mechanism 2, the The rotating disc 3 and the output mechanism 4 are on the same straight line.

[0031] The control unit 5 is electrically connected to the rack 1 . The control unit 5 is a PLC controller. The PLC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com