Food-grade lipstick and preparation method thereof

A food-grade lipstick technology, applied in the field of natural food-grade lipstick preparation, can solve problems such as damage to the body and nervous system, cause more serious diseases, chronic poisoning, etc., reduce water loss, protect lip skin, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

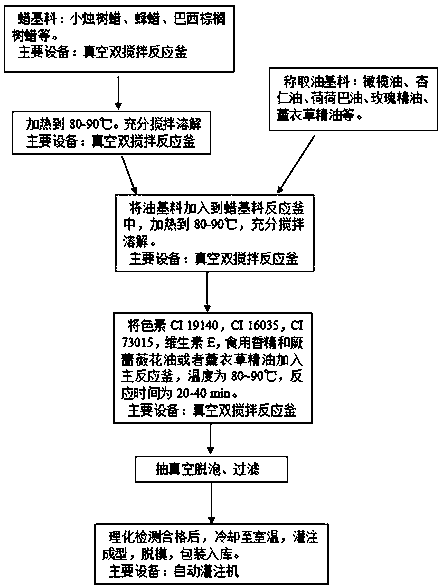

Method used

Image

Examples

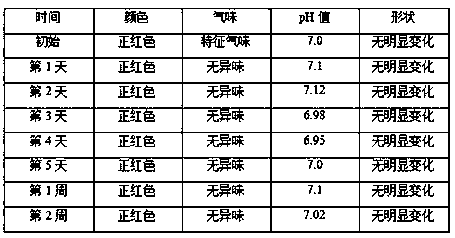

Embodiment 1

[0036] Embodiment 1: the preparation of food grade lipstick.

[0037](a) Weigh 6 grams of candelilla wax, 6 grams of beeswax, and 6 grams of carnauba wax respectively, add them to the main reaction kettle, heat and stir, the stirring speed is 50-100 r / min, and the heating temperature is 80-85 ℃, and the stirring time is 60 minutes; (b) weigh 20 grams of olive oil, 10 grams of almond oil, and 5 grams of jojoba oil. Add the mixed oil into the main reaction kettle with a stirring speed of 50 r / min, a mixing temperature of 85°C, and a stirring time of 20 min; (c) Weigh CI 19140: 1 gram, CI 16035: 1 gram, CI73015 : 1g; Vitamin E: 1g. Add it into the main reactor, the stirring speed is 100 r / min, the stirring temperature is 90°C, and the reaction time is 40 min. (d) The aromatic agent is 1 gram of edible essence and 0.5 gram of rose rose (ROSA DAMASCENA) flower oil or lavender essential oil. Degassing is vacuum degassing, and filtration is filter cloth filtration, and the gauze m...

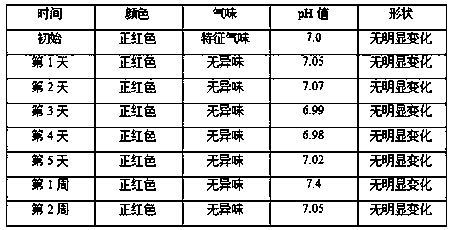

Embodiment 2

[0038] Embodiment 2: the preparation of food grade lipstick.

[0039] (a) Weigh 6 grams of candelilla wax, 7 grams of beeswax, and 6 grams of carnauba wax respectively, add them to the main reaction kettle, heat and stir, the stirring speed is 50-100 r / min, and the heating temperature is 80-85 ℃, and the stirring time is 40 minutes; (b) weigh 25 grams of olive oil, 10 grams of almond oil, and 10 grams of jojoba oil. Add the mixed oil into the main reaction tank with a stirring speed of 50 r / min, a mixing temperature of 85 °C, and a stirring time of 20 min. (c) Weigh CI 19140: 1.5 grams, CI 16035: 2 grams, CI 73015: 0.5 grams; 2 grams of vitamin E. Add it into the main reactor, the stirring speed is 100 r / min, the stirring temperature is 80°C, and the reaction time is 40 min. (d) The aromatic agent is 1 gram of edible essence and 0.5 gram of rose rose (ROSA DAMASCENA) flower oil or lavender essential oil. Degassing is vacuum degassing, and filtration is filter cloth filtrati...

Embodiment 3

[0040] Embodiment 3: the preparation of food grade lipstick.

[0041] (a) Weigh 6 grams of candelilla wax, 6 grams of beeswax, and 7 grams of carnauba wax respectively, add them to the main reaction kettle, heat and stir, the stirring speed is 50-100 r / min, and the heating temperature is 80°C. The stirring time is 40 minutes; (b) weigh 20 grams of olive oil, 15 grams of almond oil, and 10 grams of jojoba oil. Add the mixed oil into the main reaction tank with a stirring speed of 50 r / min, a mixing temperature of 85 °C, and a stirring time of 20 min. (c) Weigh CI 19140: 1.5 grams, CI 16035: 1.5 grams, CI73015: 1 gram; 2 grams of vitamin E. Add it into the main reactor, the stirring speed is 100 r / min, the stirring temperature is 85°C, and the reaction time is 40 min. (d) The aromatic agent is 1 gram of edible essence and 0.5 gram of rose rose (ROSA DAMASCENA) flower oil or lavender essential oil. Degassing is vacuum degassing, and filtration is filter cloth filtration, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com