Methyl ethyl ketone peroxide fiber recycling device applied to production of high-density fiberboards

A high-density fiberboard and fiber recovery technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve problems such as filter blockage, reduce filtration efficiency, and increase labor intensity of workers, so as to improve efficiency, The effect of simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

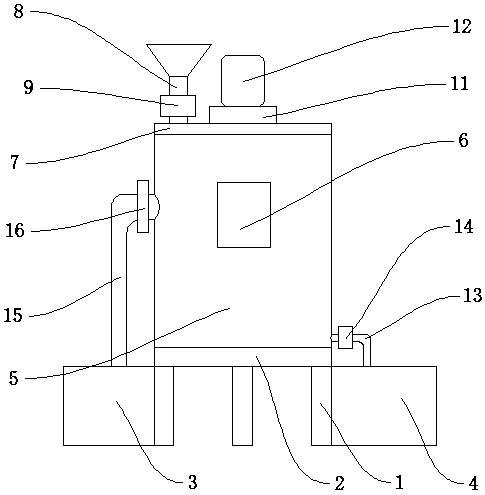

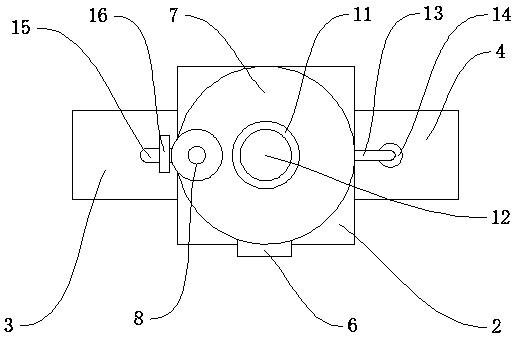

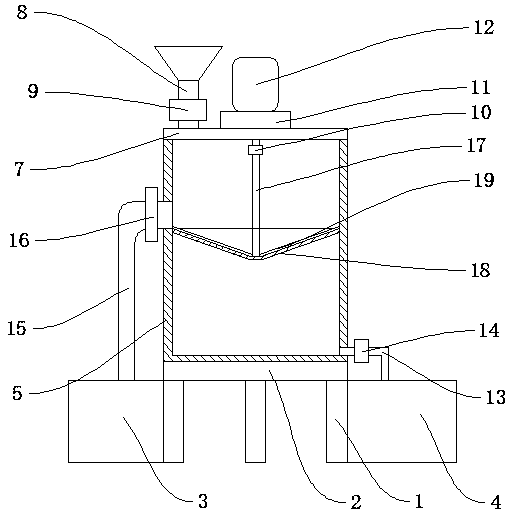

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as Figure 1-Figure 3 As shown, a white water fiber recovery device applied to the production of high-density fiberboard, including a support base 2, a filter chamber 5, a stirring motor 12, a filter screen 18, a support leg 1 is arranged under the support base 2, and both sides of the support leg 1 A fiber recovery box 3 and a white water recovery box 4 are arranged respectively. The fiber recovery box 3 and the white water recovery box 4 decibels are used to recover fibers and white water. A filter chamber 5 is arranged above the support base 2, and the filter chamber 5 is used for recovery and filtration of white water fibers. To provide a working space, a top cover plate 7 is set above the filter chamber 5, a feed hopper 8 and a motor support 11 are set above the top cover plate 7, a feed control valve 9 is set on the feed hopper 8, and the feed control valv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap