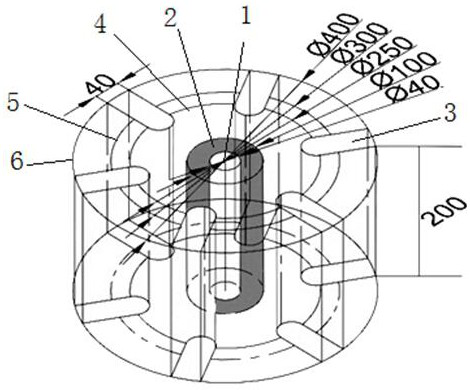

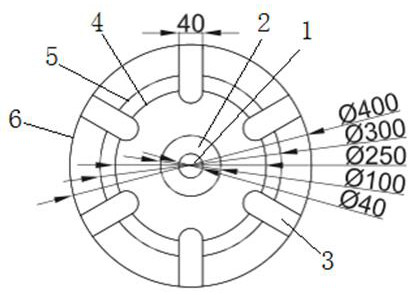

Soil heavy metal remediation device with switchable array electrodes

An array type, heavy metal technology, applied in the field of soil pollution remediation of environmental technology, can solve the problems of large remediation range, long remediation gap, and few variable factors, and achieve low cation exchange capacity, good test repeatability, and expanded remediation range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The test cycle is closely related to factors such as heavy metal pollution concentration, voltage gradient, and water content. First, do a general test to estimate the test cycle; the pollution concentration of Cd is 300mg / kg, the control voltage gradient is 1.5v / cm, and the water content is 30%. , PRB dielectric material adopts zeolite (particle size 1-2mm): zero-valent iron = 1; 1, the test was repaired to the fifth day, and the Cd removal rate was calculated to be 88.2% in the middle of the two electrodes, which was extended from the fifth day to the eighth day The removal rate increased to 92.4% in one day, and the removal rate was 94.1% after extending to the 10th day. The removal rate has reached a relatively high level on the 5th day, and the increase in the removal rate is not obvious when the time is extended, and the remaining Cd may be in a residue state that is not easy to remove. Comprehensively considering the repair time and removal rate, the test period ...

Embodiment 2

[0036] Estimate the soil weight of the filling height (10-15cm) according to the kaolin bulk density and the volume of the soil chamber. Taking the inner ring as an example, the kaolin bulk density is 1.24g / cm 3 , it is expected to fill about 15cm, and the kaolin required for calculation is about 7.5kg. The amount of Cd poisoning in the expected soil is 300mg / kg, and the Cd(NO 3 ).4H 2 O 6.1775g was dissolved in deionized water, and added to the soil to be tested after dissolving, the total amount of deionized water added in the process was 2.25L (to keep the moisture content of the soil at 30%), fully stirred and mixed evenly and retained a sample. Electrolyte solution: 0.1mol / LNaNO3; Citric acid-sodium citrate buffer solution (pH=5), also can use the citric acid of 0.1mol / L as electrolyte solution, voltage gradient is 1.5v / cm, PRB material is mass ratio zeolite ( 1-2mm): Fe 0 =1:1. Set 5 sampling points between the two electrodes, and take samples and record changes in cu...

Embodiment 3

[0040] 7.5kg of kaolin was used in the test, and the poisoning amount of Cd in the expected soil was 300mg / kg, and the poisoning amount of Cu was 500mg / kg, and the Cd(NO 3 ) 2 .4H 2 O 6.1775g, Cu(NO3) 2 .3H 2 O 14.1796g, the total amount of deionized water added in the process is 2.25L (to keep the moisture content of the soil at 30%), fully stir and mix and retain the sample. Electrolyte solution: 0.1mol / LNaNO3; Citric acid-sodium citrate buffer solution (pH=5), also can use the citric acid of 0.1mol / L as electrolyte solution, voltage gradient is 1.5v / cm, PRB material is mass ratio zeolite ( 1-2mm): Fe 0 =1:1, after 24 hours of balance, start timing from power on, take samples and record every 24 hours, and finally analyze and calculate the removal rate of each point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com